How to judge and deal with these abnormal phenomena in transformers?

1. Analysis of abnormal operation of transformers

(1) The sound of the transformer is abnormal

As soon as the transformer is connected to the power supply, there will be a buzzing sound, which is mainly due to the effect of high-voltage magnetic flux. During normal operation, the sound of the transformer is uniform. When there are other noises, you should carefully find the cause and deal with it.

Audited supplier

Audited supplier1. The sound of the transformer is larger than usual, and the sound is uniform. There may be the following reasons:

(1) Overvoltage occurs in the power grid. When a single-phase grounding occurs in the power grid or a resonance overvoltage occurs, the sound of the transformer will increase.

(2) When the transformer is overloaded, the transformer will make a heavy "hum" sound. If the load of the transformer is found to exceed the allowable normal overload value, the transformer load should be reduced according to the regulations on site.

Solution: analyze the reasons, make records, strengthen monitoring, and restore the transformer to normal operation as soon as possible. If it is caused by overload, it shall be carried out in accordance with the principle of overload treatment.

2. The transformer has noise

There may be vibrations caused by loose parts on the transformer. If the sound of the transformer is significantly increased, and the current and voltage are not abnormal, it may be caused by the loosening of the internal clamp or the screw pressing the iron core, which increases the vibration of the silicon steel sheet.

Treatment method: If it does not affect the operation of the transformer, it can be temporarily not dealt with, make records, strengthen monitoring, report and dispatch, and apply for power outage inspection and processing by relevant leaders.

3. The transformer has discharge sound

The transformer has a "crackling" discharge sound. If you see blue corona or sparks near the transformer bushing at night or in rainy weather, it means that the porcelain parts are seriously dirty or the equipment line cards are in poor contact. If the transformer is internally discharged, it is the electrostatic discharge of the ungrounded components or the inter-turn discharge of the coil, or the discharge due to the poor contact of the tap changer.

Solution: At this time, the dispatcher and relevant leaders should be reported to apply for power failure inspection of the transformer.

4. The transformer has a popping sound

Indicates that the internal or surface insulation of the transformer is broken down, and the transformer should be stopped immediately for inspection.

5. The transformer has the sound of water boiling

If the transformer has the sound of water boiling, and the temperature changes sharply and the oil level rises, it should be judged that the transformer winding is short-circuited or the tap changer is in poor contact caused by serious overheating, and the transformer should be stopped immediately for inspection.

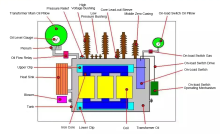

(2) The upper oil temperature is high

Usually, the oil temperature of the upper layer of the transformer should be detected during operation, and the temperature of the windings should be controlled by supervising the oil temperature of the upper layer to prevent the insulation level from dropping and aging. Under normal load and normal cooling conditions, the transformer oil temperature is more than 10°C higher than usual or the transformer load remains unchanged, and the oil temperature continues to rise. Fault (such as iron core fire and short circuit between winding turns, etc.). At this time, the transformer should be stopped immediately to prevent the transformer accident from expanding.

(3) The oil color is abnormal

Normally, the transformer oil should be bright yellow and transparent. When it is found that the color of the oil in the oil level gauge changes during operation, you should contact to take oil samples for laboratory analysis. If the color of the transformer oil suddenly deteriorates during operation, and there is carbon in the oil and other abnormal phenomena, the power should be cut off immediately for inspection and treatment.

(4) The oil level is abnormal

The oil pillow of the transformer is equipped with an oil level gauge, which generally shows three oil level lines when the temperature is -30°C, +20°C, and +40°C. According to these three marking lines, it can be judged whether it is necessary to refuel or drain.

High oil level:

When the oil level of the transformer in operation is too high or the oil overflows from the oil pillow, you should first check whether the load and temperature of the transformer are normal. false oil level. At this time, with the consent of the dispatcher on duty, the gas (heavy gas) protection should be changed to the signal, and then the respirator should be cleared for processing. If the oil pillow overflows due to the high ambient temperature, it should be drained.

Low oil level:

If the oil level of the transformer is too low, the gas (light gas) protection will act; when there is a serious lack of oil, the iron core and windings will be exposed to the air, which is easy to be affected by moisture and may cause insulation breakdown. Refuel. If the oil level drops rapidly due to a large amount of oil leakage, below the gas relay or continues to drop, the transformer should be stopped immediately.

(5) Overload

When the transformer in operation is overloaded, the indication of the ammeter exceeds the stable value, the signal, the alarm bell, etc. may appear. Operators should handle it according to the following principles:

①Check whether the current on each side exceeds the specified value, and report to the duty officer on duty.

②Check whether the oil level and oil temperature of the transformer are normal, and put all the coolers into operation at the same time.

③ Adjust the operation mode in time. If there is a spare transformer, it should be put into operation.

④Contact scheduling and adjust the load distribution in time.

⑤ In the case of normal overload, the allowable operating time can be determined according to the multiple of the overload, and the monitoring of oil level and oil temperature shall be strengthened, and the allowable value shall not be exceeded. If the time is exceeded, the load should be reduced immediately.

⑥ In case of accidental overload, the allowable multiple and time of overload shall be implemented according to the regulations of the manufacturer. If the overload multiple and time exceeds the allowable value, the compliance of the transformer should also be reduced according to regulations.

⑦ Carry out a comprehensive inspection of the transformer and its related systems. If any abnormality is found, it should be reported and dealt with.

(6) Failure of cooling system

When the transformer cooling system (referring to the submersible pump, cooling water system) is faulty, and the transformer sends out the chiller standby input and the chiller full stop signal, the following measures should be taken:

1. It should be checked immediately whether the backup cooler has been put into operation.

2. Immediately check the cause of the power outage and restore the normal operation of the cooling device as soon as possible.

3. Strengthen the monitoring of the oil temperature and oil level of the upper layer of the transformer, especially during the full stop time of the cooling device.

4. If the cooling system cannot be restored for a while, an application should be made to reduce the load or apply for the transformer to be withdrawn from operation to prevent the transformer from running for more than the specified non-cooling time, resulting in overheating and damage.

(7) Gas protection action

Reasons for gas shielding action may be:

1. There is a slight fault in the transformer, which produces weak gas;

2. Air intrudes into the transformer;

3. The oil level decreases;

4. Secondary circuit fault (such as two-point grounding of DC system, etc.), causing malfunction.

After the gas protection signal appears, the operator should immediately conduct an external inspection of the transformer. First, check the oil level and oil color in the oil pillow, whether there is gas, gas volume and color in the gas relay, and then check whether there is oil leakage in the transformer body and the forced oil circulation system. At the same time, look at changes in transformer load, temperature and sound, etc. After external inspection, if no abnormal phenomenon is found, the gas gas of the transformer should be absorbed to find out the nature of the gas, and if necessary, the oil sample should be taken for testing to jointly determine the nature of the fault.

(8) The parts and causes that are prone to heat during operation

1. The tap changer is in poor contact

Poor contact leads to increased contact resistance, increased consumption, and severe heat generation. This is especially likely to happen after a tap change and when the transformer is overloaded.

2. Short circuit between turns of winding

Turn-to-turn shorts are insulation damage between adjacent turns. This will create a closed short-circuit loop and reduce the number of winding turns for that phase. There is a short-circuit current induced by the alternating magnetic flux in the short-circuit loop, which will generate high heat and may cause the transformer to burn out.

3. There is a short circuit between the iron core silicon steel sheets

Due to external force damage or insulation aging and other reasons, the insulation of the paint skin between the silicon steel sheets is damaged, which will increase the eddy current, cause local overheating, and even melt in severe cases. This is the so-called iron core fire.

4. Poor contact of other parts causes local overheating.

Handling advice: closely monitor the temperature changes of the overheated parts to ensure safe operation, analyze the causes of overheating, contact scheduling, and deal with power outages.

2. Accident handling of transformers

General: According to 6.1.2 of DL/T572-95 "Operating Regulations for Power Transformers":

If the transformer has one of the following conditions, it should be stopped immediately. If there is a spare transformer in use, it should be put into operation as soon as possible:

a. The sound of the transformer is obviously increased, which is very abnormal, and there is a popping sound inside;

b. Serious oil leakage or oil injection, so that the oil level drops below the indicated limit of the oil level gauge;

c. The casing has serious damage and discharge;

d. The transformer catches fire with smoke.

(1) Automatic trip of the transformer

After the transformer trips automatically, the following inspections and treatments should be done:

①After the automatic tripping of the transformer, the operator should carry out systematic treatment, that is, put the backup transformer into operation, adjust the operation mode and load distribution, and maintain the operation system and its equipment in normal condition.

②Check what kind of protective action and whether the action is correct.

③ Understand whether the system is faulty and the nature of the fault.

④The following conditions can be tested once without external inspection: personnel accidentally touch, operate and protection malfunction; only low-voltage overcurrent or time-limited overcurrent protection operates, and at the same time, the next-level equipment of the tripping transformer fails and its protection does not operate. and the point of failure is isolated.

⑤ If it is a differential, gas protection or quick-break overcurrent protection and other protection actions, and there is an impact in the event of a fault, it is necessary to carry out a detailed inspection of the transformer and its system, power outage and measure the insulation. It is forbidden to put the transformer into operation until the cause has not been identified or dealt with.

(2) Gas protection action (tripping)

When the gas protection action of the transformer trips, the following inspections and treatments should be done:

a) Collect the gas of the gas relay for chromatographic analysis. If there is no gas, check whether the wiring posts and leads of the secondary circuit and the gas relay are well insulated.

b) Check whether the oil level, oil temperature and oil color have changed;

c) Check whether the explosion-proof pipe is broken and inject fuel;

d) Check whether the transformer shell is deformed and whether the welding seam is sprayed.

e) If no abnormality is found after inspection, and it is confirmed that the malfunction is caused by the fault of the secondary circuit, the gas protection can be connected to the signal or withdrawn under the condition that the differential protection and overcurrent protection are turned on, test the power once, and strengthen monitor.

f) If there is gas in the gas relay or there are problems with the above items a, b, c, and d, the power failure inspection should be carried out and corresponding treatment should be carried out.

(3) Transformer overcurrent protection action

When the transformer overcurrent protection action trips, the following inspections and treatments should be done:

a) Check the busbar and the equipment on the busbar for short circuit and debris;

b) Check whether several test equipments of the transformer are short-circuited;

c) Check whether the protection on the low-voltage side is activated, and whether the protection of each line is activated.

d) When it is confirmed that the busbar has no power, the line carried by the busbar should be opened.

e) In case of bus failure, consider switching the bus or transferring the load.

f) When it is confirmed that it is a leapfrog trip after inspection, you should contact the dispatcher on duty and try sending power once.

g) When the test power supply is good, check the faulty line one by one.

h) If it is caused by the circuit, the power can be sent only after eliminating the fault factor.

(4) Transformer differential protection action

After the transformer differential protection action trips, the following inspections and treatments should be done:

a) Check whether the transformer is abnormal, check whether the insulators within the differential protection range have flashover, damage, and whether the leads are short-circuited.

b) If there is no obvious fault in the equipment within the differential protection range, check whether the relay protection and the secondary circuit are faulty, and whether the DC circuit is grounded at two points.

c) There is no fault in the above inspection, and after reporting to the chief engineer for approval, the step-up pressure test should be carried out when the load is disconnected, and put into operation after good.

d) If it is a misoperation caused by the electrical circuit, secondary circuit, etc., with the consent of the chief engineer, the differential protection can be withdrawn and the transformer can be put into operation.

e) When the differential protection and gas protection act simultaneously to trip the transformer, the transformer shall not be put into operation without internal inspection and test.

(5) Transformer catches fire

Transformer fire treatment principles: power failure - oil discharge - fire extinguishing.

① Power failure: If the transformer catches fire, if the protection does not automatically trip, the circuit breakers and isolating switches connected to it should be disconnected first, and the cooler should be withdrawn to disconnect its power supply. If the operation of the adjacent equipment is endangered, it should also be contacted in time to stop the operation of the adjacent equipment.

② Oil discharge: If the oil overflows on the top of the transformer and catches fire, open the oil discharge valve at the lower part of the transformer and discharge the oil to the accident oil pool, so that the oil level of the transformer is lower than the fire surface; if the internal fault of the transformer causes fire, it cannot be drained. oil to prevent explosion; if the transformer casing is ruptured and oil overflows, close the transformer oil pool drain electric valve, open the oil drain electric valve, and drain the oil to the main transformer accident oil pool.

③ Start the fire water pump, open the fire water valve and spray the transformer to extinguish the fire.

④ Report to the superior and activate the emergency plan.

⑤ Notify the fire department for assistance.

Note: Participate in firefighting without endangering personal safety. It is best to use carbon dioxide, carbon tetrachloride, dry powder fire extinguishers and dry sand when putting out the fire; fire extinguishers should wear gas masks.

Audited supplier

Audited supplier

How to judge and deal with these abnormal phenomena in transformers?

55 Transformer Knowledge You Have to Know

Transformer No-load/Load Test Introduction

What is the main power transformer factory look like

Attending the MIDDLE EAST ELECTRICITY in March

China The Main Power Transformers manufacturers - Canwin

The Knowledge About Power Transformer-Oil Tank Part

The knowledge about "Power Transformer" is all here, Very Comprehensive, Collect it and Learn it!

What impact might the Russian-Ukrainian conflict have on the motor industry? Supplier