The Knowledge About Power Transformer-Oil Tank Part

The main content of the transformer oil tank section is the types of transformer oil tanks.

The transformer oil tank is the container that holds the body and transformer oil. Its main functions are:

Oil container

Heat dissipation

Protective insulation: isolate insulation from the atmosphere, avoid absorbing moisture and gas, and prevent oil aging

Dry insulation: Acts as a "vacuum tank" when vacuuming at room temperature on site

Pedestal

Transportation

Audited supplier

Audited supplierType of fuel tank:

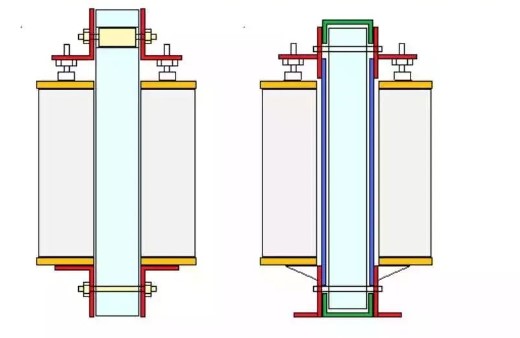

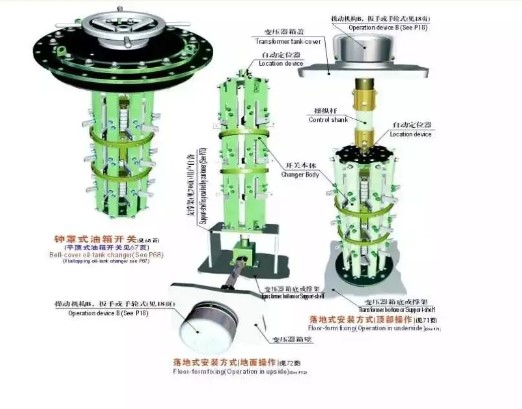

There are two basic types of transformer tanks: barrel tanks and bell tanks.

The barrel type fuel tank is composed of two parts: the tank cover and the barrel body. The advantage is that the appearance is simple, and the hanger body only needs to put a little oil; the disadvantage is that for large-capacity transformers, a crane with a large enough lifting capacity is required for on-site maintenance.

The bell-type fuel tank consists of an upper fuel tank and a lower fuel tank. Its advantages and disadvantages are opposite to that of the barrel tank.

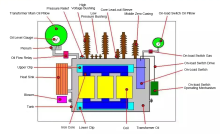

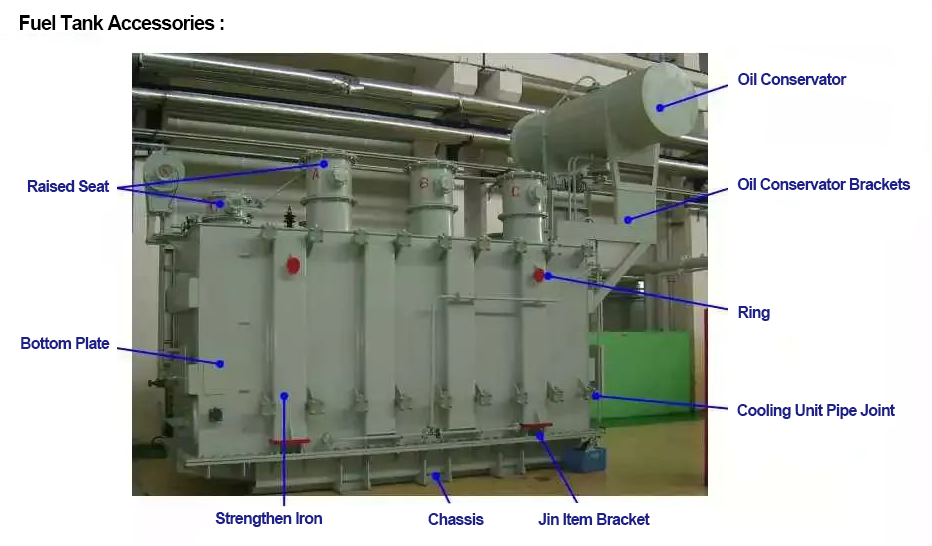

The structure of the fuel tank:

There are two basic types of transformer tank structure: reinforced tank and corrugated tank.

The reinforced fuel tank is an additional reinforced iron on the bottom plate of the fuel tank to enhance the strength of the fuel tank. There are buckle-type reinforced iron and plate-type reinforced iron.

●The corrugated fuel tank is made of corrugated fuel tank plate to enhance the strength of the fuel tank. There is no difference in principle between the two types of fuel tanks

Groove Oil Tank

Plate shape Oil Tank

The structure of the fuel tank:

There are two basic types of transformer tank structure: reinforced tank and corrugated tank.

The reinforced fuel tank is an additional reinforced iron on the bottom plate of the fuel tank to enhance the strength of the fuel tank. There are buckle-type reinforced iron and plate-type reinforced iron.

●The corrugated fuel tank is made of corrugated fuel tank plate to enhance the strength of the fuel tank. There is no difference in principle between the two types of fuel tanks

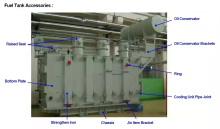

Accessories of the tank

Transportation of the Tank

Transformer assembly

Transformer body

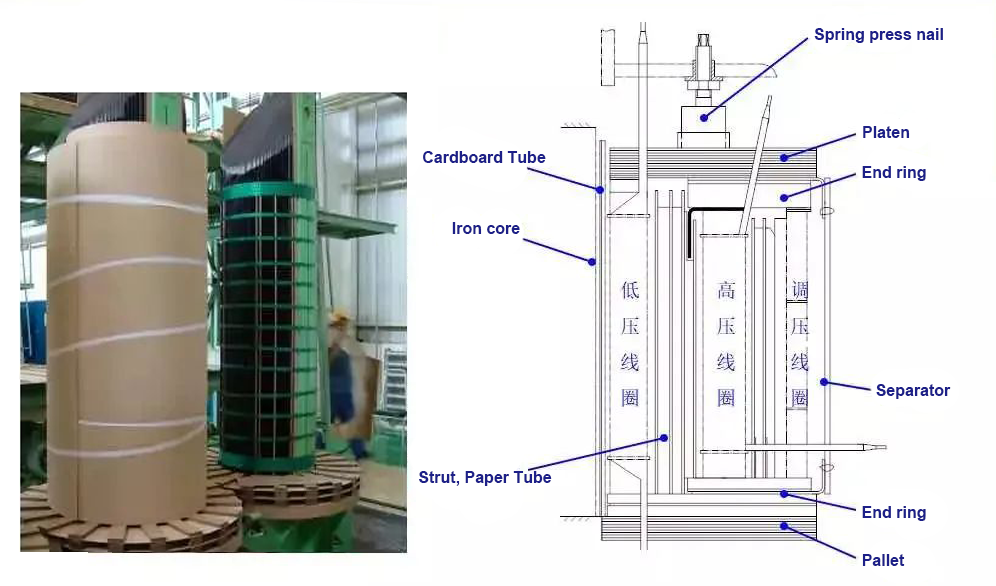

The main content of the transformer body part is the fastening technology of transformer core and winding.

The iron core and the coils of various voltage levels are assembled together, the compression device is added, and the leads are welded to form a whole, which is called the body of the transformer. Therefore, the transformer body generally includes iron core clamps and coil compression.

Fastening of the body:

Amplitude tightening of the coil is a means of keeping the coil to the core and the coil to the coil in a concentric position. In addition, the inner coil is subjected to pressure when it is subjected to short-circuit electromagnetic mechanical force in the amplitude direction, and requires a firm fulcrum. Therefore, the amplitude direction tightening of the inner coil of the large-capacity transformer is very important.

The reliability of the manufacturing quality of the transformer depends to a large extent on the axial tightening of the coil, which can resist the action of the short-circuit axial electromagnetic mechanical force and eliminate the loosening of the coil.

Boil Nail/Laminated cardboard/pad nails

Pull belt type transformer body

Old style transformer body

Part II Transformer Components

The main content of the transformer components section is the function of the transformer components

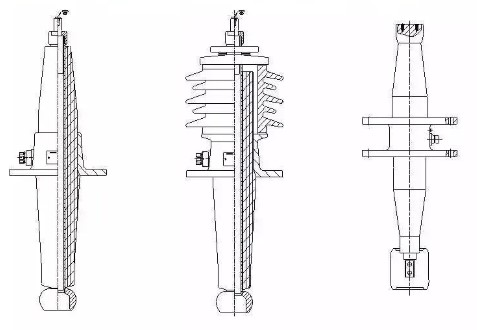

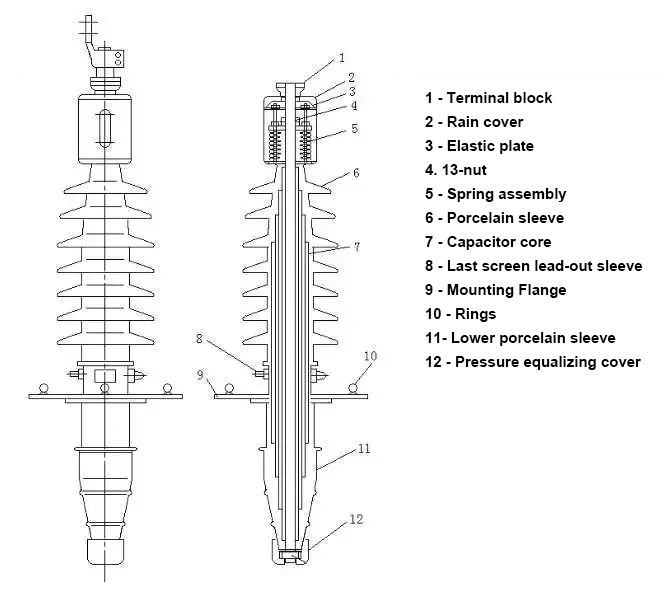

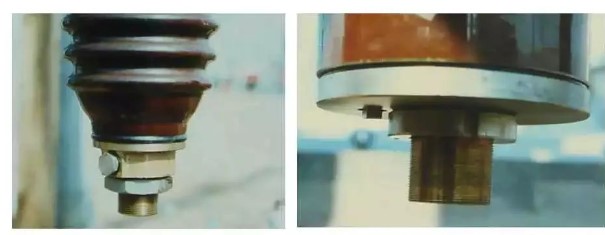

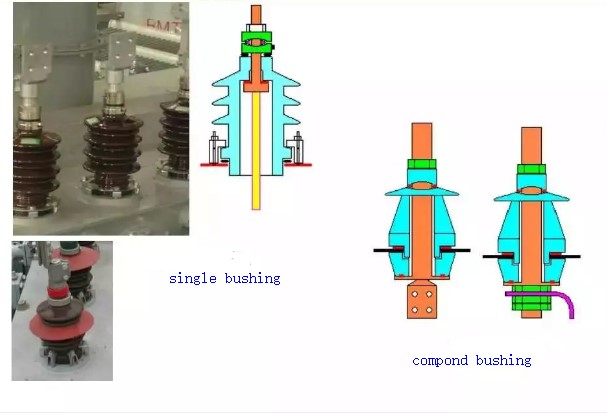

1. Transformer assembly bushing

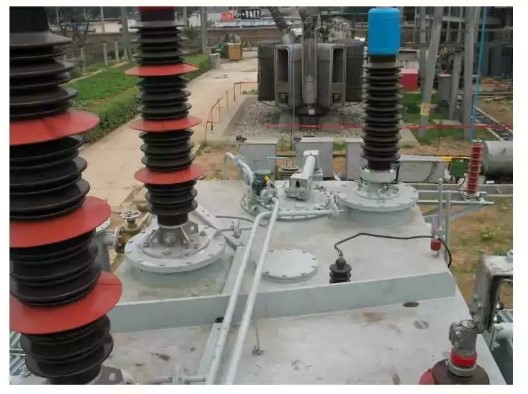

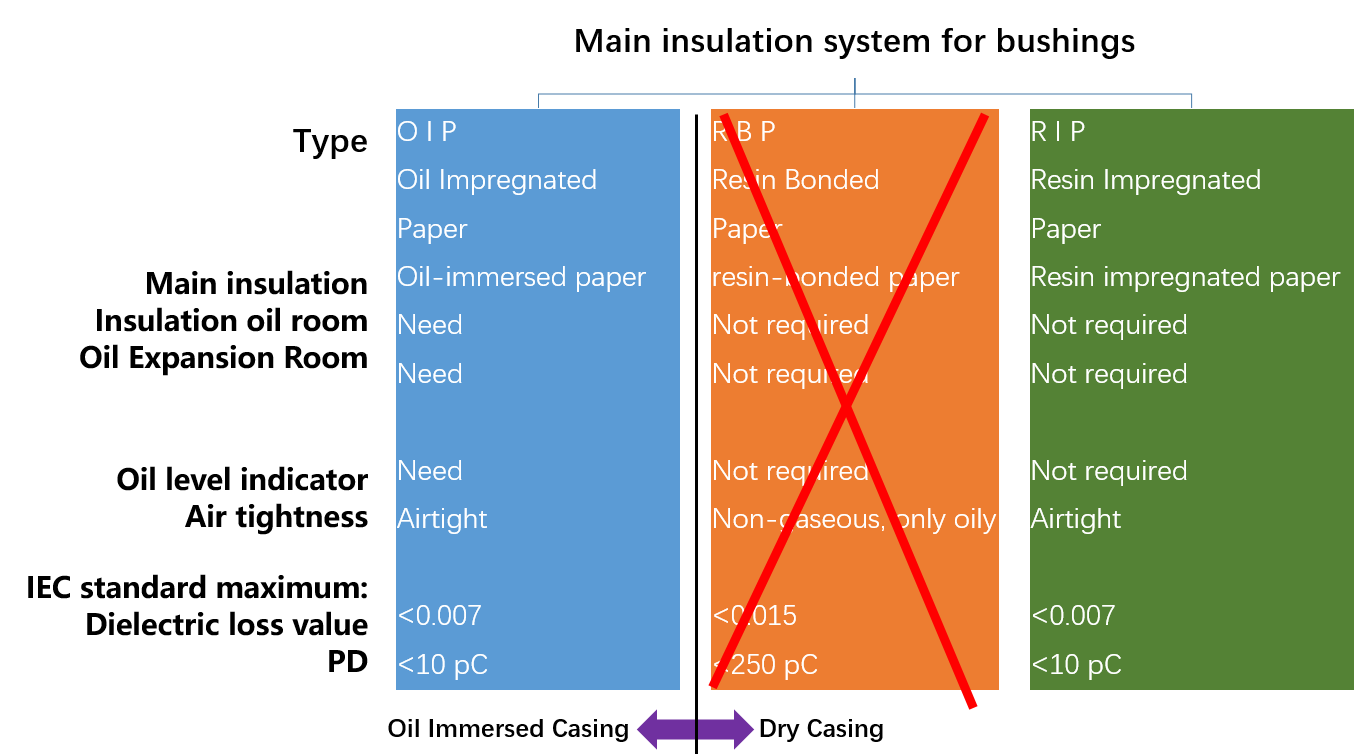

The bushing of the transformer is the outlet device that leads the high-voltage and low-voltage leads inside the transformer to the outside of the oil tank. It not only serves as the insulation of the lead to the ground, but also plays the role of fixing the lead.

Transformer assembly bushing

Transformer Assembly - Tap Switch

In order to make the power grid supply stable voltage, control the power flow or adjust the load current, it is necessary to adjust the transformer voltage.

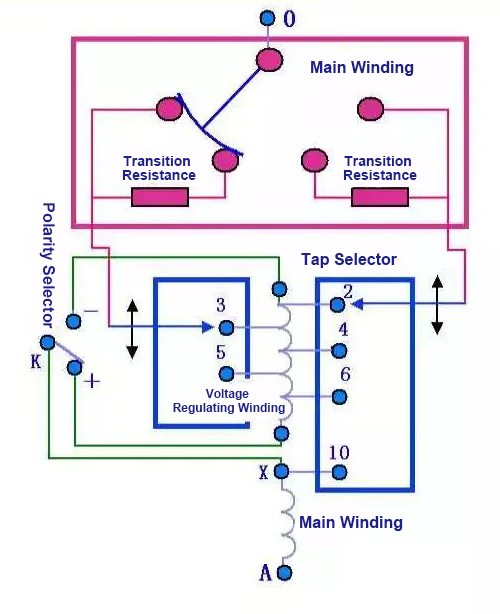

At present, the transformer voltage adjustment method is set on a side of the coil tap, in order to remove or increase a part of the line turns, change the number of turns, so as to change the voltage ratio of the stepwise voltage adjustment method. The component used to transform tap to regulate voltage is called tap switch.

In general, the appropriate tap is drawn on the high voltage coil. This is because a high voltage coil is usually set outside, leading to the tap is convenient: second, the high voltage side current is small, the tap lead and tap switch current carrying part of the section is small, switch manufacturing is easy.

Voltage regulation without excitation (no-load voltage regulation): voltage regulation with switching coil tapped with load is called on-load voltage regulation.

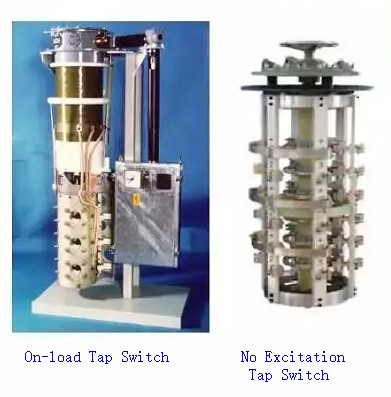

Therefore, transformer tap switch is divided into two kinds, one is no excitation tap switch, two is loaded tap switch.

On-load Tap Switch

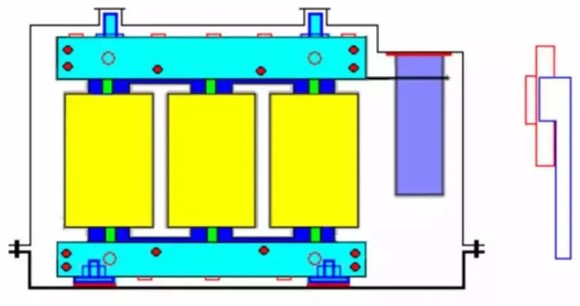

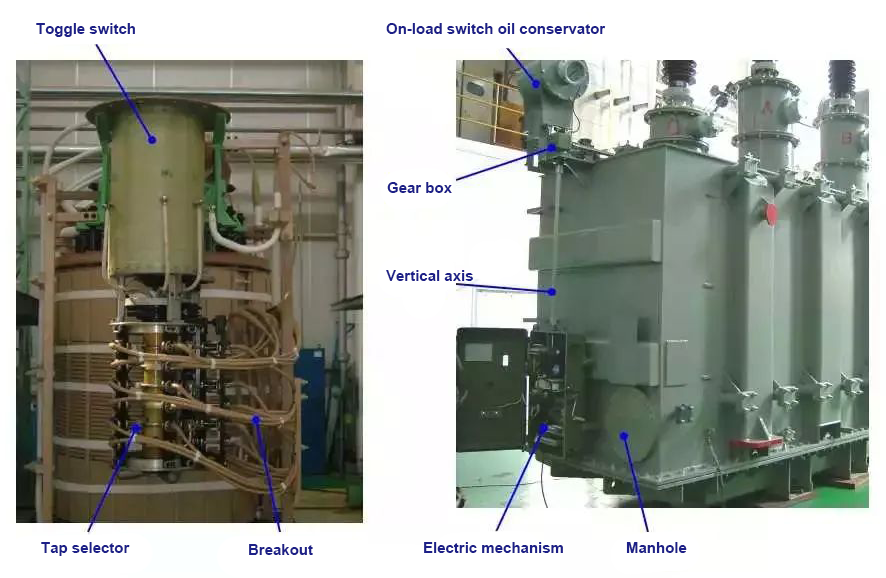

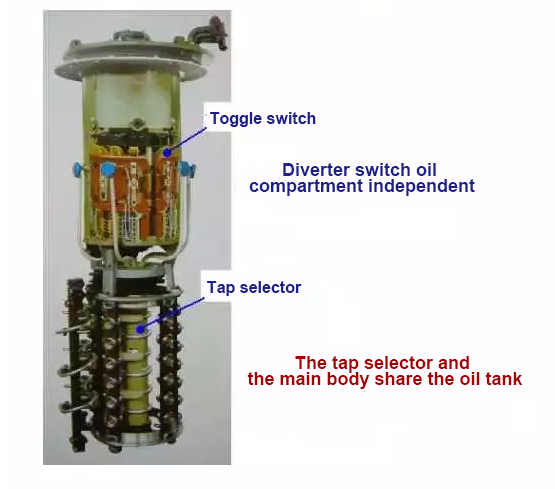

Transformer on-load tap-changers are divided into two types in structure: composite and combined on-load tap-changers.

The compound structure is to combine the functions of the switch and the tap selector to form a selector switch, which not only undertakes the selection of the tap but also undertakes the switching of the load current, forming an integral plug-in structure.

The combined structure is composed of two separate parts: the diverter switch placed in the oil chamber and the tap selector are combined, and the tap selector is installed under the diverter switch oil chamber. The tap changer is hung on the transformer tank cover as a whole.

There are two types of changeover switches: M-type on-load switch represented by German MR and ABB's UC-type on-load switch. Domestically produced on-load switches are basically German MR-type on-load switches.

Automatic voltage regulator: used in conjunction with the on-load tap-changer, the transformer can automatically adjust the voltage. The automatic voltage regulator also provides a digital remote transmission port to realize remote control.

Online oil filter device: to reduce the number of power outages for the transformer to replace the switch oil. The filter element is a composite filter element with impurity removal and water filtering functions.

Electric mechanism:

Control function - local/remote conversion up/down control

Transformer assembly without excitation tap switch

The unexcited tap switch can change the tap of the transformer to change the voltage ratio of the transformer under the condition that the transformer does not apply voltage.

Non-excitation tap switch can be divided into single phase and three phase according to the number of phases; According to the pressure regulating position can be divided into neutral point pressure regulating, middle pressure regulating and line end pressure regulating three.

Transformer assembly - off-circuit tap-changer

The off-excitation tap-changer can change the tap of the transformer to change the voltage ratio of the transformer under the condition that the transformer does not apply voltage.

The off-excitation tap-changer can be divided into single-phase and three-phase according to the number of phases; according to the voltage regulation position, it can be divided into three types: neutral point voltage regulation, middle voltage regulation and line end voltage regulation.

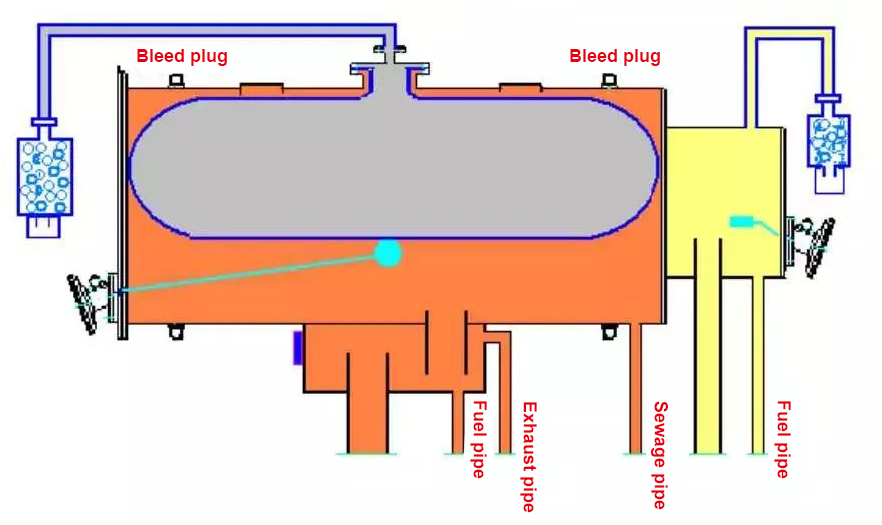

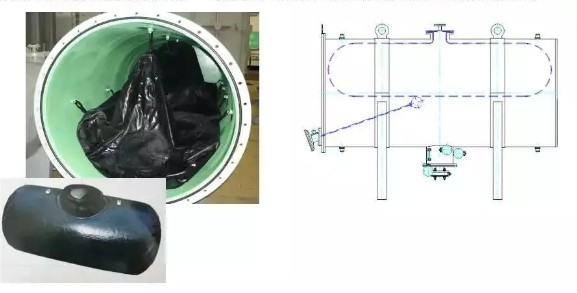

Transformer Assembly-Oil Conservator

The oil conservator can be divided into two types: open type and sealed type, of which the sealed type can be divided into capsule type, diaphragm type and metal corrugated type. Capsule type oil conservator: mainly consists of cabinet body, capsule, gas collection chamber (main oil tank pipeline, oil injection and discharge pipeline, exhaust pipeline, sewage oil pipeline, small tube oil meter and other components on the gas collection chamber), It is composed of moisture absorber and pipeline, air drain plug, oil drain plug, oil level gauge and other components.

Transformer Assembly-Oil Conservator

This kind of oil conservator uses a capsule as a seal to isolate the transformer oil from the atmosphere. The outside of the capsule is transformer oil, and its inner cavity is communicated with the atmosphere through the moisture absorber pipeline, so that the pressure in the oil conservator is the same as the atmosphere. Among the three types of sealed oil conservators, the capsule type oil conservator is the most widely used. Compared with the diaphragm type, it has the advantages of better manufacturing process and convenient operation and operation. No matter in the world or in China, the capsule oil conservator is replaced by the capsule type oil conservator. Diaphragm oil conservators are a big trend. All transformer oil conservators operated by our company are of capsule type.

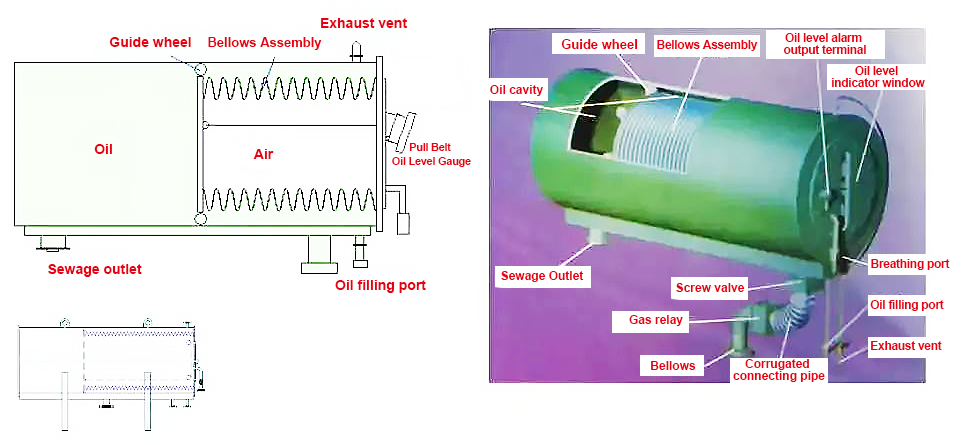

Bellows type oil conservator:

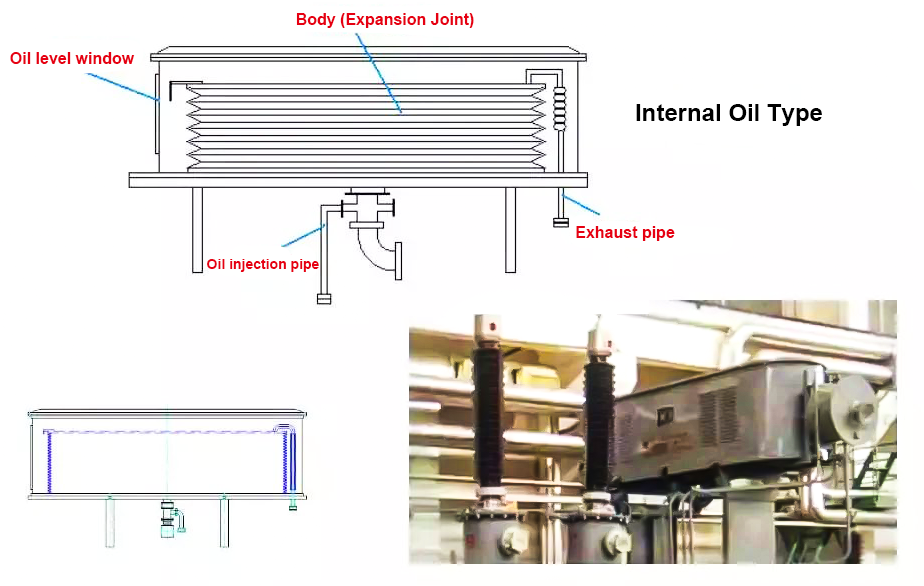

This kind of oil conservator uses a metal corrugated expander made of stainless steel sheet as a seal to isolate the transformer oil from the atmosphere. Metal corrugated oil conservator can be divided into two types: external oil type and internal oil type.

External oil type

Transformer Assembly-Oil Conservator

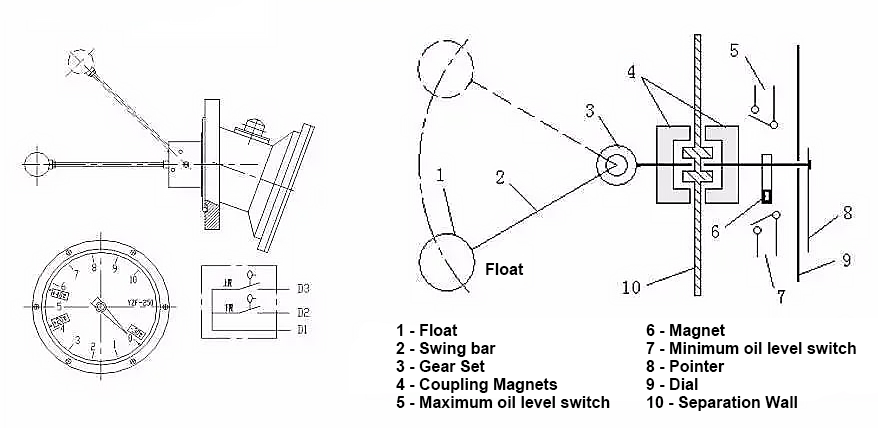

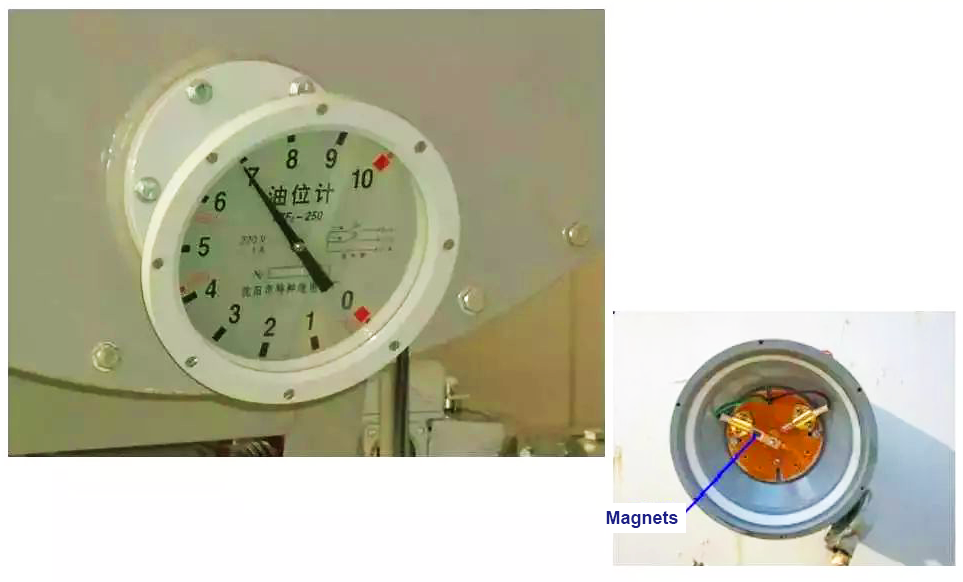

Capsule-type oil conservator generally adopts domestic YZF-250 magnetic oil level gauge, and the upper and lower limit positions engage the reed contacts to send out the oil level alarm signal. Its biggest feature is that the active magnetic steel and the passive magnetic steel are completely isolated by the partition plate, relying on the magnetic force to drive the torque, which can prevent the transformer oil in the oil conservator from leaking to the dial.

Transformer Assembly-Oil Conservator

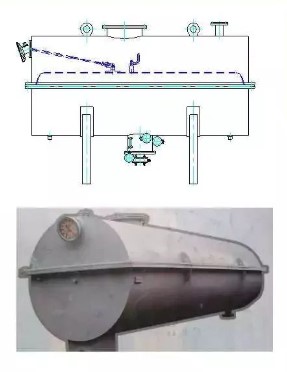

Diaphragm type oil conservator: mainly consists of upper section cabinet body, lower section cabinet body, diaphragm, gas collection chamber (main oil tank pipeline, oil injection and discharge pipeline, exhaust pipeline, sewage oil pipeline, small pipe on the gas collection chamber It is composed of components such as type oil gauge), moisture absorber pipeline, oil drain plug, oil level gauge and other components. This kind of oil conservator uses the diaphragm between the upper section and the lower section of the cabinet as a sealing member.

It is separated from the transformer oil and the atmosphere, and has the same function and material as the capsule. The upper and lower sections of this oil conservator

The sealing surface between the cabinets is large and rectangular,

It is not easy to manufacture and the flatness of the sealing surface is not easy to ensure, which is easy to cause oil leakage. When filling the oil conservator

It is necessary to open the hand hole on the upper cabinet body, and discharge the gas in the transformer oil through the exhaust hose on the diaphragm. That's it.

3. Transformer component-breathing system

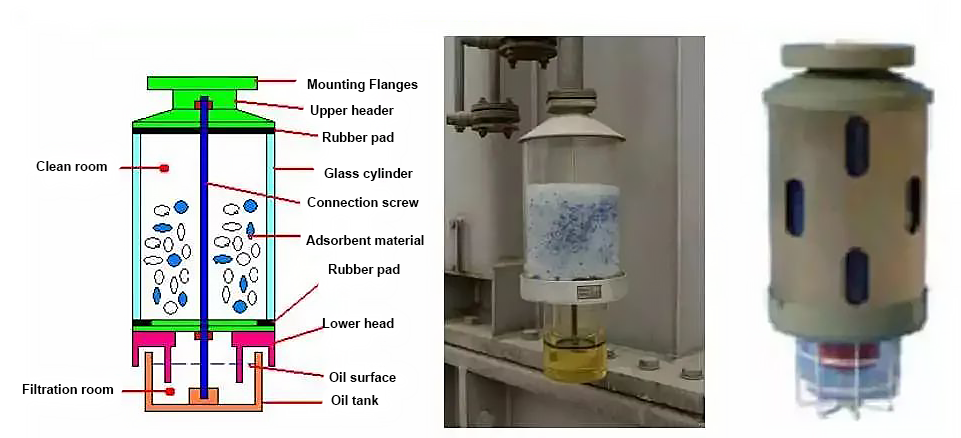

The moisture absorber is an air purification device. On the open transformer of the oil system, it is mainly to prevent moisture from immersing in the transformer oil and damping the transformer oil. After the oil conservator uses the capsule, the function of the moisture absorber is still to prevent moisture from entering and causing water accumulation inside the capsule. At present, there are two kinds of commonly used dehumidifiers, the ordinary glass shell type and the XS2 type dehumidifier which is promoted by our bureau. 75% spherical fine-pored silica gel mixed with 25% blue indicating silica gel, so not all blue.

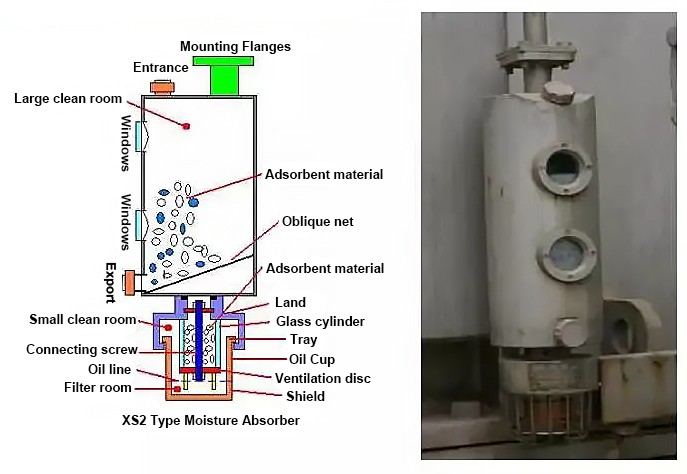

The xs2 type respirator is mainly composed of a filter room, a small clean room and a large clean room. The air first passes through the filter room (oil bowl) to remove dust and impurities, then enters the small clean room for rough purification, and finally enters the large clean room for deep purification. In order to achieve the purpose of removing air moisture. The main function of the small clean room is to prevent the adsorption material of the large clean room from being polluted by oil.

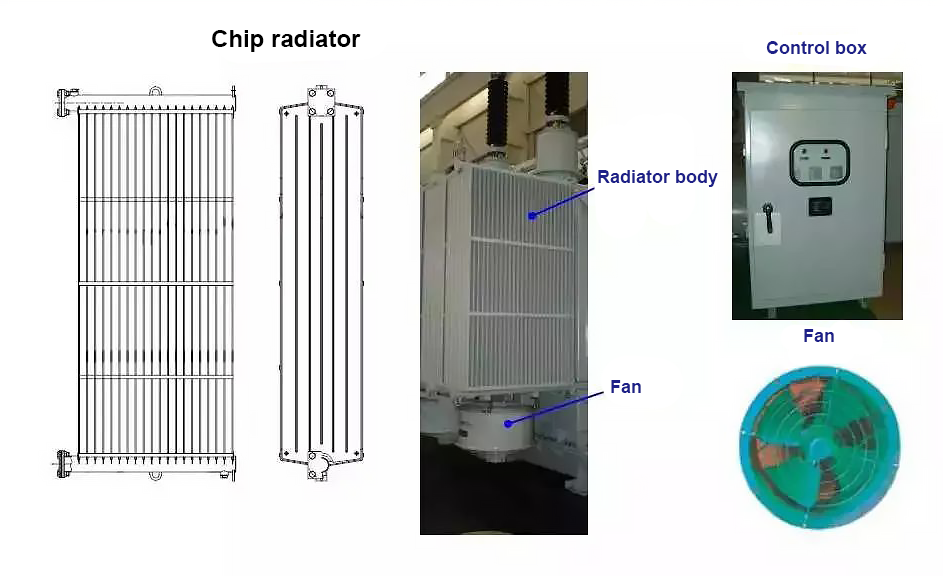

4. Transformer component-cooling system

The cooling system of the transformer is a device that dissipates the heat generated by the loss of the transformer during operation to ensure the safe operation of the transformer.

The cooling methods of 110kV power transformers are divided into: self-cooling and air-cooling.

flat tube radiator

5. Transformer components - temperature measurement system

Transformer thermometers are used to measure the temperature of the top layer of transformer oil and the temperature of transformer windings. Because the safe operation and service life of the transformer are closely related to the operating temperature, the transformer standards correspondingly specify the temperature of the top layer of oil and the temperature of the windings during operation of the transformer. average temperature. The transformer temperature is usually measured using a pressure thermometer.

The main parts of the pressure thermometer are the indicating instrument, the temperature bulb and the capillary tube. These three parts form a closed system. The temperature bulb is placed in the thermometer seat with the same oil temperature as the transformer. The temperature bulb is filled with temperature-sensing liquid. When the temperature of the transformer changes At the same time, the volume of the temperature-sensing liquid also changes, and this change is transmitted to the indicating instrument through the capillary. There is an elastic element in the indicating instrument, which converts the volume change into mechanical displacement and drives the instrument pointer to indicate.

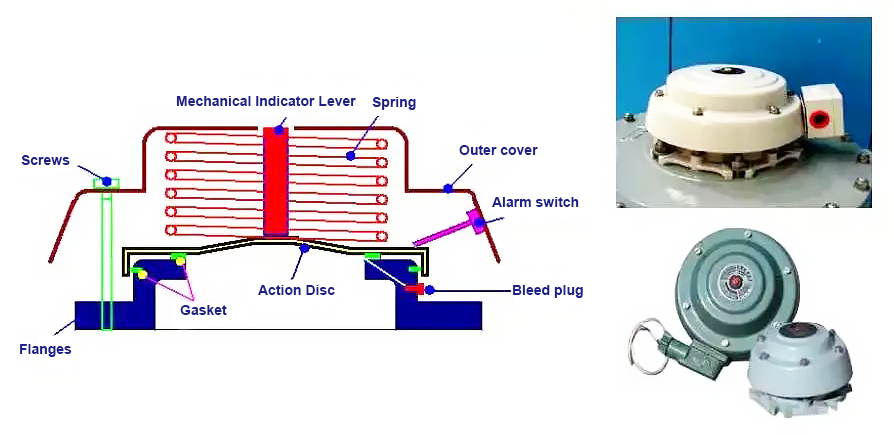

6. Transformer assembly-pressure relief valve

The transformer pressure relief valve is a type of ejector valve. When the internal pressure exceeds the opening force of the spring, the action plate moves upward slightly, and the internal pressure immediately spreads to the area of the action plate sealed on the side, causing the action plate to open suddenly, the internal pressure of the transformer drops rapidly, and the spring makes the action plate return to the sealing position. The pressure relief valve can provide an alarm switch, which can be reset manually after the action. The mechanical indicator lever is a visual indicator.

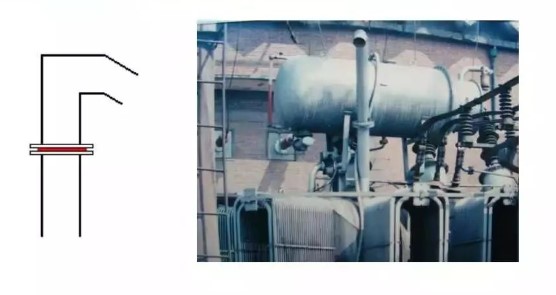

Transformer Assembly - Pressure Relief Cartridge

The transformer pressure release cylinder is an early transformer pressure release device. The middle of the release cylinder is equipped with a pressure release plate (usually flat glass), and there is a net cover below to prevent the glass from falling into the transformer after breaking. This pressure relief cartridge has been phased out and is still used on some older transformers.

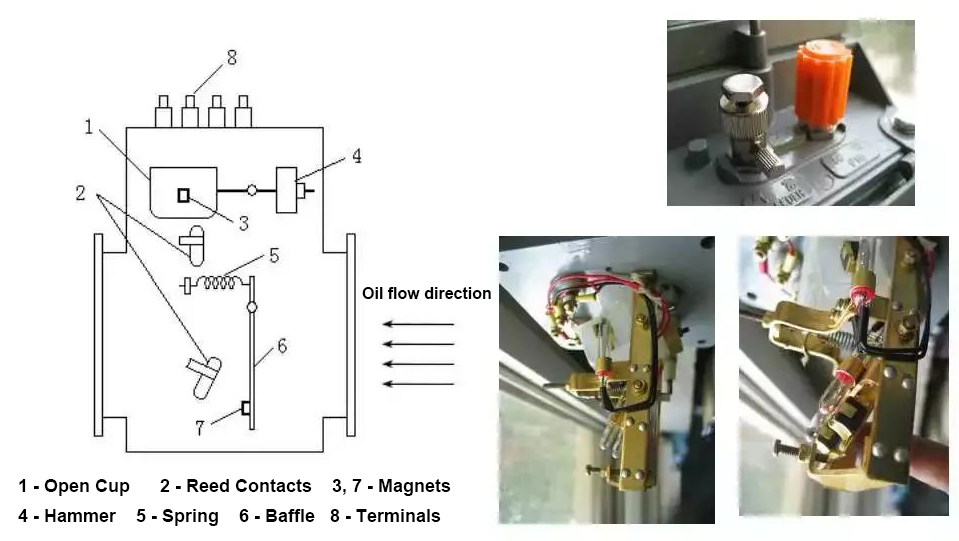

Gas Relay

Accessories

Audited supplier

Audited supplier

How to judge and deal with these abnormal phenomena in transformers?

55 Transformer Knowledge You Have to Know

Transformer No-load/Load Test Introduction

What is the main power transformer factory look like

Attending the MIDDLE EAST ELECTRICITY in March

China The Main Power Transformers manufacturers - Canwin

The Knowledge About Power Transformer-Oil Tank Part

The knowledge about "Power Transformer" is all here, Very Comprehensive, Collect it and Learn it!

What impact might the Russian-Ukrainian conflict have on the motor industry? Supplier