What impact might the Russian-Ukrainian conflict have on the motor industry? Supplier

Russian President Vladimir Putin signed an order on the evening of the 21st to recognize the "Donetsk People's Republic" and "Luhansk People's Republic" in eastern Ukraine. On the 24th local time, Russian President Vladimir Putin said in an emergency televised speech that he had decided to conduct a special military operation in the Donbas region.

Audited supplier

Audited supplierA summary from a netizen: "The 4-hour 'speed pass' record in Denmark held by Adolf Hitler was refreshed by Vladimir Putin at 1 hour and 22 minutes on February 24, 2022."

Although the conflict continued until March 1, it is undeniable that we, living in the present, have once again witnessed history. In recent years, the global economy has once again taken an unpredictable path due to the Russian-Ukrainian armed conflict after being "critically hit" by factors such as the new crown epidemic, blocked supply chains, and soaring raw material prices. What we need to be concerned about is that this What impact will it bring to China and the global motor industry?

Industry insiders said that if the situation in Russia and Ukraine continues to escalate, not only steel, but also these kinds of motor raw materials may also be severely impacted.

The drive motor is mainly composed of stator components, rotor components, end covers and auxiliary standard parts, and the stator windings also include iron cores, copper wire windings, insulating materials, etc. As the name suggests, the flat wire motor uses flat copper wire in the stator winding.

Russia's refined copper production in 2021 is 920,000 tons, accounting for about 3.5% of the global total, of which Russia's production is 406,841 tons. Copper prices are at all-time highs due to soaring demand, especially in the developed world, increasing use of electric vehicles, wind farms, solar panels and grids, coupled with tight supplies.

Goldman Sachs estimates that copper demand will grow by nearly 600% to 5.4 million tonnes by 2030, largely thanks to the green transition. Copper prices are expected to rise as the copper concentrate market is very tight, especially in China, where demand outstrips supply. Goldman Sachs has a 3- and 12-month price target of $11,500 a tonne.

Sanctions on Russia could lead to tighter supplies and another short-term rally.

In addition, according to a report released by market research agency Techcet at the beginning of the month, many semiconductor manufacturers around the world are more dependent on some materials from Russia and Ukraine, such as neon and palladium. The report estimates that more than 90 percent of U.S. semiconductor-grade neon supply comes from Ukraine and 35 percent of palladium comes from Russia.

A recent copy of the text issued by the Semiconductor Industry Association International (SEMI) shows that Joe Pasetti, vice president of global public policy at SEMI, has targeted semiconductors such as hexafluorobutadiene, palladium, helium, neon and scandium produced in Russia and Ukraine. The materials reminded members, "If your company is concerned about a potential supply disruption risk for any of these materials, please let me know."

Techcet pointed out that neon is essential for the lasers used to make chips and is a by-product of Russia's steel industry, while Ukrainian companies are responsible for the purification of neon. Palladium is used in sensors and memory, among other applications.

Although since yesterday, semiconductor suppliers have come forward one after another, they were aware of this danger as early as 2014 when Russia annexed Crimea, and since then the risk of disruption to the supply chain caused by the conflict between Russia and Ukraine has been minimized as much as possible. , but it is undeniable that this impact or indirect, more likely to be affected by the market.

This is undoubtedly a blow to the global auto industry chain, which has suffered from core shortages, low electricity, and rising raw material prices since the epidemic, and the next trend will be even more difficult to predict.

In order to minimize the risk of increasing supply chain risks, more and more countries and related companies have taken corresponding measures. For example, Nippon Steel Co., Ltd. plans to purchase more iron ore from Brazil and Australia to prevent iron Ore supply disruptions and make up for the lack of iron ore supply. The company currently sources about 14 percent of its iron ore pellets from Russia and Ukraine; memory chip makers have boosted inert gas inventories from the usual 4 weeks to 6 to 8 weeks, but still can't solve long-term problems.

Canwin is manufactured according to the highest mechanical sealing standards and the product has been verified as the superior mechanical sealants.

FAQ

Advantages

About Canwin

Audited supplier

Audited supplier

How to judge and deal with these abnormal phenomena in transformers?

55 Transformer Knowledge You Have to Know

Transformer No-load/Load Test Introduction

What is the main power transformer factory look like

Attending the MIDDLE EAST ELECTRICITY in March

China The Main Power Transformers manufacturers - Canwin

The Knowledge About Power Transformer-Oil Tank Part

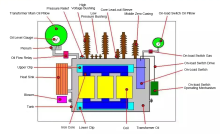

The knowledge about "Power Transformer" is all here, Very Comprehensive, Collect it and Learn it!

What impact might the Russian-Ukrainian conflict have on the motor industry? Supplier