Best bulk bag/sachet unpacking, conveying, mixing, weighing and packaging system Supplier

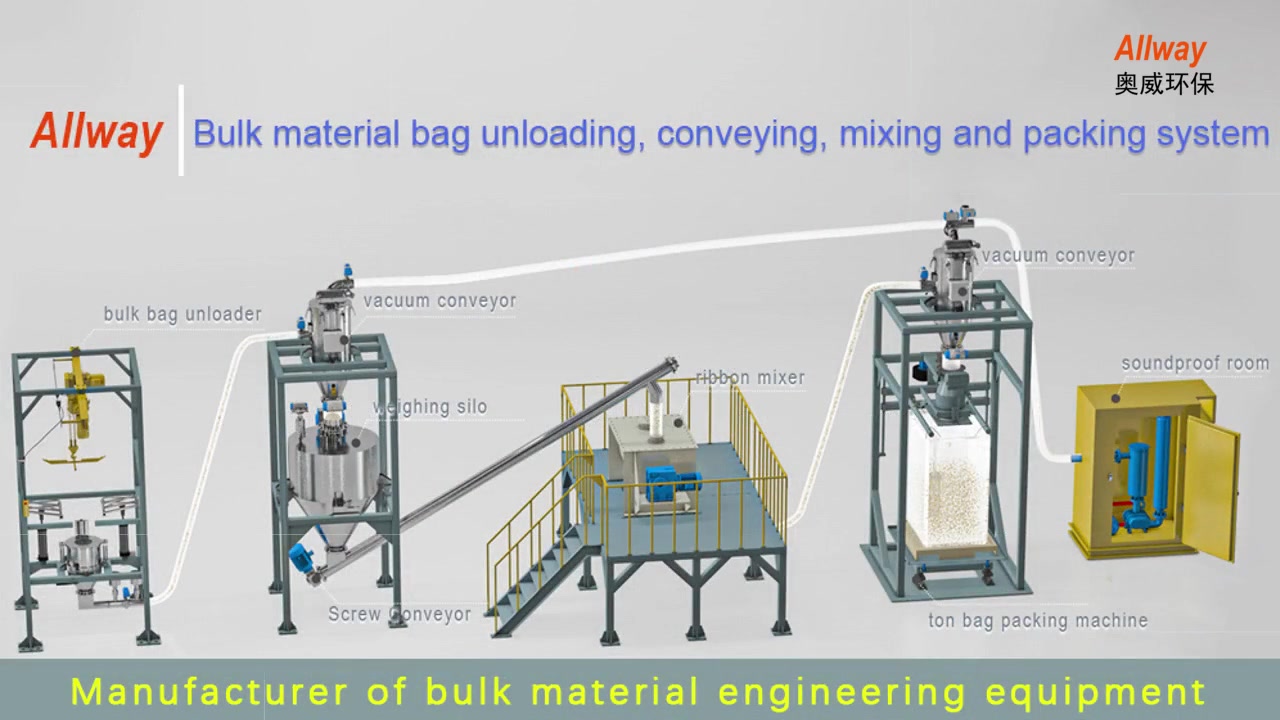

This case is a bulk bag/sachet unpacking, conveying, mixing, weighing and packaging system. This case is a specially customized vacuum conveying system for the customer, which is specially used for the airtight conveying of powder materials. This case is widely used in food, pharmaceutical, chemical, lithium battery, rubber and plastic industries.

Audited supplier

Audited supplierAmong them, in terms of unloading, the ton bag unpacker in this case has various specifications to choose from (pressed bag ton bag unpacker, unpacked bag ton bag unpacker, ton broken bag ton bag unpacker, manual feeding station, glove box feeding station, etc.), and if the raw material particles are too large or lumpy, the raw material can be pre-treated with lumpy crusher, crusher sifter, etc.

Vacuum feeding machine in addition to the case of silo, packaging machine supporting, but also with a variety of equipment, such as two three-dimensional mixer, double spiral cone mixer, reactor, crusher, vibrating sieve, granulator, boiling bed, double cone dryer, vertical mixer, Chinese medicine polishing machine, tablet press, capsule filling machine, etc.. (Vacuum feeding system can also be combined with load cell to realize automatic conveying and feeding, automatic weighing and dosing and other automatic combinations.) According to the different characteristics of materials, vacuum feeding system also has a variety of options in terms of filters (laminated cloth bag, PE filter element, stainless steel filter, titanium metal filter, etc.), the filtration precision can reach micron level. According to the different conveying continuity:also can be divided into intermittent and continuous type. The vacuum feeding machine replaces the old mechanical conveyor in the industry because of its simple structure, dust-free and environmental protection, easy cleaning and maintenance and strong applicability. Vacuum feeding system can be divided into electric vacuum feeder and pneumatic vacuum feeder according to different vacuum sources. The pneumatic vacuum feeder uses compressed air to generate negative pressure through the vacuum generator to suck the material, which is less noisy and occupies less space than the electric vacuum feeder.

Mixers are also available in a variety of sizes and are designed to meet different needs. Its function is to mix several materials evenly.

The quantitative packaging machine can be used to pack the finished product in the required amount and then transport it to the designated place by trolley or conveyor belt.

We offer the best design solutions for different needs, please contact us if you have any needs.

Product Information

Company Advantages

Frequently Asked Questions about

What is your after-sale response time if something goes wrong?

A:We have professional after-sales team 7x24 hours standby to handle your problem.

Do you offer OEM or ODM service?

A:We welcome OEM or ODM orders. Our technical department will fully support you about your project. If you want to be our agents in your area, please also contact us.

How long have you been involved in bulk material handling industry?

A:Our company was founded in 2009. We have obtained good experience in our business. We hope we can work with you.

Where is the location of your company?

A:Our factory locates in Lishui District, Nanjing City, Jiangsu Province, China. The nearest airport to our factory is 21km. Truck transportation to Shanghai port will take 3 hours.

What is the warranty of your products?

A:We offer one year warranty for all our products. If any breakdown occurs during this period, please contact us freely. Our after-sales team will help you solve the problem.

Audited supplier

Audited supplier

Best bulk bag/sachet unpacking, conveying, mixing, weighing and packaging system Supplier

Large particle material, raw material coarse screening silo

China Vertical screw conveyor manufacturers - Allway

Allway Customized | Packing Machine AWB-Ⅲ

Allway Customized | Packing Machine AWB-Ⅲ

how to install 2 sets of Bulk Bag Unloader for Barbados customer? | Allway

Unpacking machine with broken bags for Xiaoshan, Hangzhou, China - Unpacking and conveying, simultaneous dust removal

Lump crusher for customer in Hunan, China

Automatic control system for vacuum loading and conveying for customer in Beijing, China