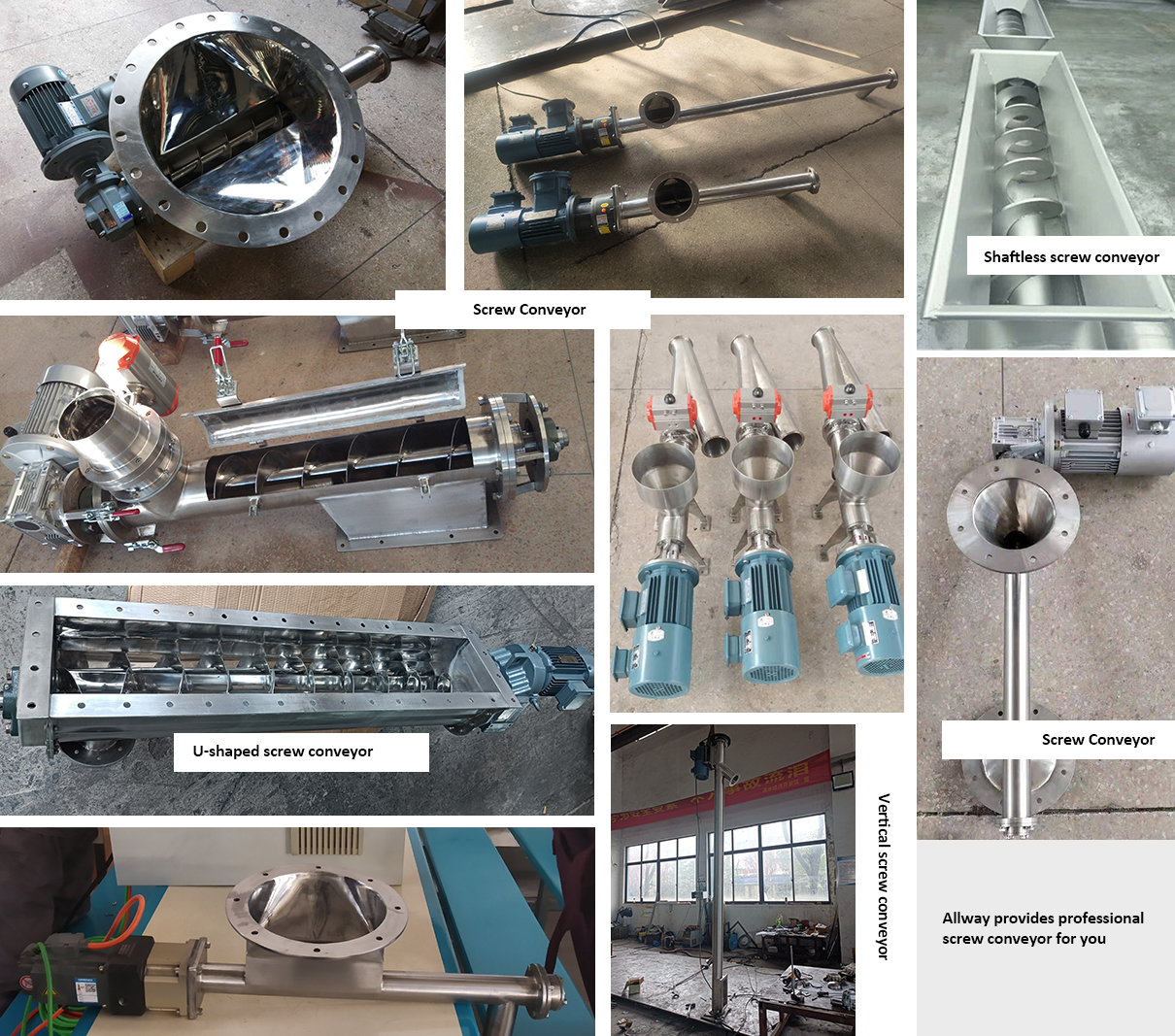

China Vertical screw conveyor manufacturers - Allway

Vertical screw conveyor rotating shaft welded spiral blade, blade surface type according to the different materials conveying vertical screw conveyor have solid surface type, belt surface type, blade surface type and other types.

The vertical screw conveyor uses the rotating spiral to convey the material along the fixed housing and carry out the conveying work, the head and tail bearings are moved to the outside of the housing, the hanging bearings are equipped with dustproof sealing devices, the shaft tiles are generally made of powder metallurgy, the felt tiles are used for conveying cement, the hanging shaft and the spiral shaft are connected by sliders.

Audited supplier

Audited supplier

The screw shaft of vertical screw conveyor has a thrust bearing at the end of the direction of material movement in order to give axial reaction force to the screw with the material, and when the length of the machine is long, the middle hanging bearing should be added.

Due to the different uses and occasions, there are many modified products of screw conveying machinery, such as LC, LS-Y type for vertical conveying, XP type and single and double tube screw feeder specifically for digesting lime, etc. There are also shaftless screw conveyor, double screw conveyor, screw conveyor, etc.

Product features:

1. Large load-bearing capacity, safe and reliable.

2. Strong adaptability, easy installation and maintenance, long life.

3. Small size of the whole machine, high speed, ensure fast and uniform conveying.

4. There is a cleaning device at the discharge end, low noise, strong adaptability, and flexible arrangement of inlet and outlet positions.

5. Good sealing, the shell is made of seamless steel pipe, and the ends are connected with each other by flanges, with good rigidity.

Use and maintenance:

The working conditions of vertical screw conveyor are poor, each bearing is surrounded by dust, and the thermal conductivity is not good, so it is especially important to operate and maintain the machine under such working conditions:

1. The screw machine should be started without load, and feed to the inlet after normal start.

2. Feeding should be evenly limited and the amount of feed should be appropriate to avoid overloading the machine.

3. Before stopping, the material should be stopped, so that the material in the casing can be stopped only after the material is conveyed.

4. The material to be conveyed should not be mixed with hard and large pieces to avoid spiral jamming and damaging the conveyor.

5. In use, check whether the linkage confinement of each part is loose, whether the power is hot, whether the sound is normal, once there is an abnormality, stop immediately to correct.

6. Speed control motor start, run, stop. After the motor starts, close the control box power switch, gradually adjust the speed knob, increase the excitation current, and gradually increase the clutch speed to the required running speed. When stopping, set the speed knob to zero and stop the motor.

7. Each refueling part should be refueled regularly.

Audited supplier

Audited supplier

Best bulk bag/sachet unpacking, conveying, mixing, weighing and packaging system Supplier

Large particle material, raw material coarse screening silo

China Vertical screw conveyor manufacturers - Allway

Allway Customized | Packing Machine AWB-Ⅲ

Allway Customized | Packing Machine AWB-Ⅲ

how to install 2 sets of Bulk Bag Unloader for Barbados customer? | Allway

Unpacking machine with broken bags for Xiaoshan, Hangzhou, China - Unpacking and conveying, simultaneous dust removal

Lump crusher for customer in Hunan, China

Automatic control system for vacuum loading and conveying for customer in Beijing, China