Our factory locates in Lishui District, Nanjing City, Jiangsu Province, China. The nearest airport to our factory is 21km. Truck transportation to Shanghai port will take 3 hours.

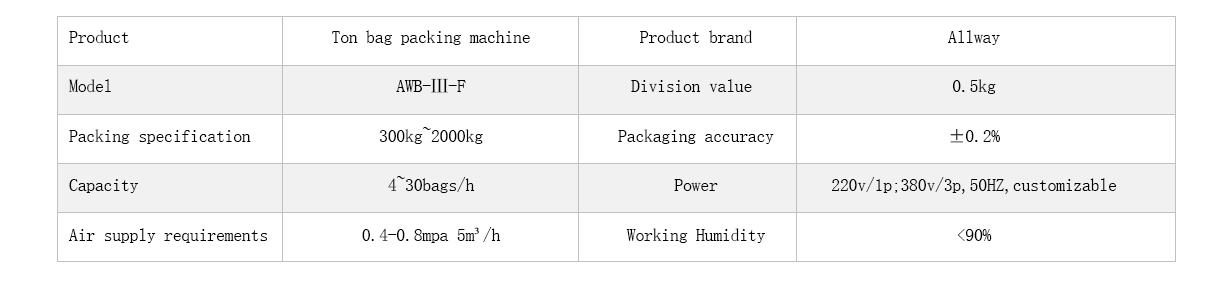

Allway Customized | Packing Machine AWB-Ⅲ

Lumps, flakes, powder, granules and other materials packaging machine - ton bag packaging machine

Ton bag packaging machine: also known as large bag automatic (quantitative) packaging machine / scale, ton bag scale.

Product composition: belt ton bag packaging machine is composed of feeding device, weighing sensor, bag clamping mechanism, steel structure support, conveying equipment, control cabinet (including control instruments) and so on.

Audited supplier

Audited supplier

Working principle: belt ton bag packaging machine working principle: using manual bag hanging, controlled by intelligent electronic control system, using belt feeding fast, medium and slow three speed feeding, to ensure the system quantitative accuracy, uniform feeding, automatic completion of feeding, weighing, discharging, automatic decoupling and other processes.

Product function:Belt ton bag packaging machine is a large weighing packaging equipment, it is a multi-purpose packaging machine integrating electronic weighing, active bag removal and dust removal in one. It has a high degree of initiative, high packaging accuracy, adjustable packaging speed, superior structure, hydraulic lifting system is particularly easy to handle the ton bag packaging, which is very convenient for the post-processing. Belt ton bag packaging machine designed for into a mixture of materials into the ton bag packaging and designed to be used to solve the problem of grain, chemical, feed, building materials, minerals and other large (500 kg or more) lumpy materials packaging. Applicable materials such as: soybean meal, coal, etc.

Product features:

The powder ton bag packaging machine weighing sensor in the bag clamping mechanism above

Weighing controller with strong anti-interference and high sensitivity function, can realize automatic compensation and correction

Weighing sensor, more accurate measurement accuracy

With coarse and fine feeding setting value, single bag weight setting value, bag counting, weight accumulation display

With automatic tare, automatic zeroing, automatic error correction, over-alarm and fault self-diagnosis, etc.

Communication interface can be configured according to the user's needs, which is convenient for online networking and DCS centralized system control.

The equipment selects different (e.g. direct current, stranded dragon, vibration) grading feeding form for feeding according to different materials, with high packing precision and fast speed.

For more requirements, please contact us, we will use our rich experience and exquisite technology to customize the product to meet your needs.

Applied range:

Product Introduction:

About Allway

FAQ

3,How can you ensure the quality of your products?

Company Introduction

Audited supplier

Audited supplier

Best bulk bag/sachet unpacking, conveying, mixing, weighing and packaging system Supplier

Large particle material, raw material coarse screening silo

China Vertical screw conveyor manufacturers - Allway

Allway Customized | Packing Machine AWB-Ⅲ

Allway Customized | Packing Machine AWB-Ⅲ

how to install 2 sets of Bulk Bag Unloader for Barbados customer? | Allway

Unpacking machine with broken bags for Xiaoshan, Hangzhou, China - Unpacking and conveying, simultaneous dust removal

Lump crusher for customer in Hunan, China

Automatic control system for vacuum loading and conveying for customer in Beijing, China