Best Quality EV battery charger cut in high end Wave Soldering machine manufacturers -DESEN TECHNOLOGY

3 years ago

679

Share

Wave Soldering is a critical process in industrial manufacturing, to get high quality products, soldering is most important, reduce the cold soldering, missed soldering, soldering short...etc, and improve the soldering PPM, we are doing below action:

- DFM to change the design

- Cut in the high quality flux

- Adopt selection wave soldering maching for the complex soldering points and PADs

- Adjust soldering temperature and other parameters

- DOE and SPC analysis

Comments

No comments received

Suppliers

DESEN Electronics Technology (DG) Co., Ltd.

Audited supplier

Audited supplier4YRS

Room 811, B4, Phase I, Guanghui Business Center, No.63, Sangyuan road, Dongcheng district, Dongguan, China

Product details

Comments

1

CONVEYOR

PCB board fixed into conveyor before manual insertion process,when all components inserted into PCB board completely, then conveyor transfer to next station

2

SPRAY FLUXER

When conveyor go into the wave soldering machine, the first step is flux spray, it makes sure next step soldering welding fully.

3

PREHEAT

The 2nd step is preheat, it's also most important process, to make sure the soldering quality, preheat the board and flux is necessary

4

SOLDERING

For most kind of boards, use the normal wave soldering machine is enough, but for some critical components or PAD need to use selective wave soldering machine to get the high soldering quality

Suppliers

DESEN Electronics Technology (DG) Co., Ltd.

Audited supplier

Audited supplier4YRS

Room 811, B4, Phase I, Guanghui Business Center, No.63, Sangyuan road, Dongcheng district, Dongguan, China

You may also like

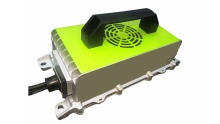

China reprogrammable battery charger 24V50A 48V35A 72V25A for forklift golfcart e-motocycle Supplier

Hot sale - 24V10A Sealed Battery Charger for e-Sweeping car sweeper forklift

Battery Charger

Fast smart battery charger 48V 72V 96V 144V for heavy Forklift Vehicles

1500W Series Battery Charger

900W Series Battery Charger

750W Series Battery Charger

Professional Waterproof Forklift fast Battery Charger 24V100A - DESEN Technology

China Full certificates Waterproof Battery Charger 450W Series - DESEN Technology