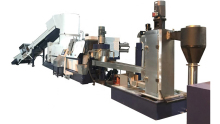

China Plastic PP PE Films Woven Bags Granulating Machine Line manufacturers-Elant

Application of Plastic PP PE Films Woven Bags Granulating Machine:

Applicable plastic materials: PP, HDPE, LDPE, LLDPE, TPV, ABS and PS, etc.

Material types: Woven bag, printed LDPE film, film (rolls,loose,bundled), agricultural film waste, foamed plastics(EPS) and raffia.

Audited supplier

Audited supplierApplication of PP Films Woven Bags Granulating Machine:

Applicable plastic materials: PP, HDPE, LDPE, LLDPE, TPV, ABS and PS, etc.

Material shapes: Film rollers

Material types: Woven bag, printed LDPE film, film (rolls,loose,bundled), agricultural film waste, foamed plastics(EPS) and raffia.

High efficiency and high performance.

This series PP plastic bags recycling machine have high effectively exhausting, filter, screen changer.

Material is cut, pre-dried, pre-heated, pre-homogenized and compacted in the shredding drum.

Many materials can be processed directly without need of the upstream pre-shredding, resulting in a dramatic reduction in operational costs.

Less power consumption cost per kilogram, high throughput, reduced floor space occupation and operator attendance.

Working Process of PP Bags Woven Bags Granulating Machine:

No. | Name | Qty. |

1 | Belt conveyor & metal detector | 1set |

2 | Compactor | 1set |

3 | Single screw extruder(one stage or double stage) | 1set |

4 | Hydraulic screen changer | 1set |

5 | Plastic pelletizing system(water-ring cutting system or strand pulls cutting system) | 1set |

6 | Dewatering machine | 1set |

7 | Air transmission and silo storage | 1set |

1. Belt conveyor & Metal detector

- The plastic material feed through belt conveyor get into the compactor.

- Metal detector can be installed on conveyor, to protect the compactor and extruder machine.

2. Cut Compactor unit

- The rotatory blades of compactor will cut up incoming scraps.

- Frictional heating which caused by high speed rotatory blades and stationary blades will heat and let scraps shrinking just below their agglomerating point.

- Optimal designed guide structure compacts the material and directs it into extruder screw.

3. Extruder unit

- A specialized single screw extruder applied to gently melt the pre-compacted material.

- The plastic scraps will be well melted, plasticized in the extruder.

- With double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiency, especially suitable to heavy printed film and material with some water content.

4. Hydraulic filtration unit

- A screen changer can be installed before die head to remove some metal, wood, dust, paper such impurities to get high quality output plastic melt.

5. Plastic pelletizing system of Plastic PP PE Films Woven Bags Granulating Machine

●Die-face water ring pelletizing system set as the standard granulating method to get uniform size plastic pellets.

●The pellets would be cooled by water and dried by centrifugal dryer and finally conveyed into storage silo.

6. Dewatering machine

a) Centrifugal removing moisture of plastic granules/pellets less than 1%.

7. Electric control components

●Top brand components. ●PLC controller and HMI screen.

●One button start & stop. ●Multi-language operating system.

Technical Specifications of PP PE films Woven Bags Granulating Machine:

Model | ECS85 | ECS100 | ECS130 | ECS160 | ECS180 | |||

Output | PP | 120KG | 250KG | 400KG | 600KG | 800KG | ||

HDPE | 150KG | 300KG | 500KG | 700KG | 1000KG | |||

LDPE | 180KG | 400KG | 600KG | 800KG | 1200KG | |||

Machine weight | 4000KG | 6000KG | 8000KG | 12000KG | 15000KG | |||

Total power | 140KW | 215KW | 325KW | 420KW | 590KW | |||

| Compactor diameter | φ800mm | φ1000mm | φ1200mm | φ1300mm | φ1500mm | ||

Blade(rotary/stable) | 6/5 | 6/12 | 9/12 | 9/13 | 12/15 | |||

Motor | 37KW | 55KW | 90KW | 110KW | 160KW | |||

Extruder | Type | The degassing zone is designed by properties of different material | ||||||

Screw diameter | φ85mm | φ100mm | φ130mm | φ160mm | φ180mm | |||

L/D | 33/1 | 33/1 | 33/1 | 30/1 | 30/1 | |||

Screw rotary speed(RPM) | 0-120 | 0-120 | 0-120 | 0-120 | 0-120 | |||

Barrel heating power | 24KW | 35KW | 54KW | 75KW | 120KW | |||

Barrel cooling method | BY AIR | BY AIR | BY AIR | BY AIR | BY AIR | |||

Temperature control zone | 0.3KWx4 | 0.3KWx5 | 0.5KWx5 | 0.5KWx5 | 0.5KWx6 | |||

Motor power | 55KW | 90KW | 132KW | 185KW | 250KW | |||

Screen changer | Type | Two position plate hydraulic screen changer(without stopping machine and will not influence the final output) | ||||||

Heating | 7KW | 10KW | 16KW | 20KW | 30KW | |||

Temperature control zone | 1 | 1 | 1 | 1 | 1 | |||

Oil pump | 1.5KW | 2.2KW | 3KW | 3KW | 3KW | |||

Die & cutting system | Die mode | Round shape die plate | ||||||

Heating power of die | 5KW | 6KW | 10KW | 10KW | 10KW | |||

Cutting method | Die face cutting system | |||||||

Cutting motor power | 1.5KW | 1.5KW | 2.2KW | 2.2KW | 2.2KW | |||

Temperature control zone | 1 | 1 | 1 | 1 | 1 | |||

Water pump | 2.2KW | 3KW | 4KW | 4KW | 4KW | |||

Power of centrifugal dryer | 2.2KW | 3KW | 4KW | 5.5KW | 7.5KW | |||

●Ability:

ELANT pelletizing system with superior quality which have high productivity for PP/PE/PS/ABS/BOPP/CPP plastic could get high property output pellets.

●Stability:

The pelletizing system is available for 24 hours working non-stop operation.

●Efficiency:

The pelletizing system have very low consumption values for electricity, water and labor.

●Control:

Intelligent automatic control of pelletizing system reduces the labor operation, makes the whole system easier and more reliable to control.

●Service:

Consistently quick and careful service in pre-sales and after-sales process. Overseas installation, commissioning and training are available.

Audited supplier

Audited supplier

Best HDPE rigid plastic pelletizing machine Supplier

China PPR Pipe Shredder Machine EL-P800 manufacturers -

China LDPE film washing recycling machine 800-1000kghr manufacturers -

PE film recycling pelletizer machine 500kghr

LDPE LLDPE HDPE Film Plastic Pelletizing Machine Supplier

Plastic PP PE rigid flakes recycling granulating machine

PP PE squeezed films recycling pelletizing machine

HDPE PP rigid plastics strand recycling pelletizing machine

PP woven bags, non woven fabric, raffia recycling granulating machine