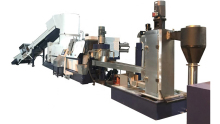

Best HDPE rigid plastic pelletizing machine Supplier

Usage: To recycle rigid plastic PE PP PVC ABS PC,etc. flake into PE PP PVC ABS PC pellets.

·Main machine: Single screw extruder, Granulator Screw: Single screw

·Raw material: Rigid Plastic Flakes

Rigid plastic flake pelletizing recycling machine line with high output and excellent granulating ability (200kg/hour to 1000kg/hour).

Audited supplier

Audited supplierI. HDPE rigid plastic pelletizing machine line features:

1. HDPE rigid plastic pelletizing machine with high output and excellent granulating ability (200kg/hour to 1000kg/hour);

2. Rigid plastic flake granulation recycling machine line is widely used to recycle waste plastic PE PP PVC ABS PC, etc. flake into PE PP PVC ABS PC pellet;

3. Simple structure, easy operation, large capacity, energy-saving, safety, eco-friendly way;

4. Automatic controlling, compacted structure, excellent production ability,perfect granulating ability 5.Processing material: PE PP PVC ABS PPC, etc. flake;

6.You can choose single stage (one extruder with one screen changer)or double stages(mother-baby two

extruders with two screen changers) based on raw material clean degree & real production needs.

7.You can choose water-ring cutting or cold-strand noodle cutting or die-face cutting way to match different raw material.

HDPE rigid plastic pelletizing machine feature:

1. Stable and uniform for material entrance

2. High capacity, easy operation

3. Applicable for wet and lightweight material

4. .Below 5% moisture, suitable to extruder

II. HDPE rigid plastic pelletizing machine detail list:

NO. | Name | Qty |

1 | Screw loader | 1set |

2 | Single screw extruder | 1set |

3 | Hydraulic screen changer | 1set |

4 | Plastic pelletizing system | 1set |

5 | Dewatering machine | 1set |

6 | Air transmission and silo storane | 1set |

Cold-strand granulating way, die-face cutting way also available with rich experience, based on raw material Condition.

III. Detailed description for HDPE rigid plastic pelletizing machine line:

Less power consumption cost per kilogram, high output, reduced floor space occupation and operator attendance.

1. Screw loader uploads the raw material by timer;

2. Single screw extruder is controlled by inverter;

3. Different L/D for different material;

4. Nature degassing, vacuum degassing adopting for moisture;

5. Water-ring/cold-strand/die-face cutting for perfect pellets shape;

Screw loader

U-type screw feeder

·Frequency conversion speed regulation ensures that the feeding amount is consistent with the extrusion amount and no blocking occurs.

Part of contacting material: stainless steel 304 ·Quantitative feeding to ensure stable feeding · Adopt material limit device.

Single screw extruder(First stage)

1st extrusion, 1st filtering

1) Gearbox: high quality Chinese brands or based on customer's request

2)Frequency inverter: Siemens brand

3) Screw & barrel: 38CrMoAl, Nitride with thickness 0.4~ 0.7 mm, Polish

4) Heater: Ceramics + stainless steel cover

5) Vacuum pump exhaust, double exhaust

6) Self-protective system:

Over current protective of motor

Over pressure protective of screw

Over temperature protective of motor

Low & over temperature control of extruder

Screw &barrel are specially designed by our engineer according to decades years'experience for good plasticizing effect & capacity.

Audited supplier

Audited supplier

Best HDPE rigid plastic pelletizing machine Supplier

China PPR Pipe Shredder Machine EL-P800 manufacturers -

China LDPE film washing recycling machine 800-1000kghr manufacturers -

PE film recycling pelletizer machine 500kghr

LDPE LLDPE HDPE Film Plastic Pelletizing Machine Supplier

Plastic PP PE rigid flakes recycling granulating machine

PP PE squeezed films recycling pelletizing machine

HDPE PP rigid plastics strand recycling pelletizing machine

PP woven bags, non woven fabric, raffia recycling granulating machine