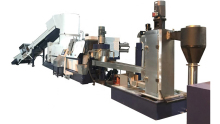

China LDPE film washing recycling machine 800-1000kghr manufacturers -

China LDPE film washing recycling machine 800-1000kghr manufacturers.

Our plastic films washing machine line is used to recycle waste plastic such as plastic bags, PP woven bags, plastic agriculture film, greenhouse films, mulching films, plastic package films, PE waste film, PP waste film, PVC waste film, industrial film, printed film and etc.

Audited supplier

Audited supplierElant is professional to supply you European design plastic films washing machine line.

Application:

Our plastic films washing machine line is used to recycle waste plastic such as plastic bags, PP woven bags, plastic agriculture film, greenhouse films, mulching films, plastic package films, PE waste film, PP waste film, PVC waste film, industrial film, printed film and etc.

But each kind of plastic films will contain different pollutants so it requires different washing process and washing line will be different. So firstly, please confirm with us that which kind of plastic films you want to recycle.

Product description:

We have 300kg/hr, 500kg/hr, 1000 kg/h Series Efficient plastic films washing recycling machine line. And We can design the washing line layout according to your requirements.

Working principle and flow chart for plastic films washing machine line:

>>After getting waste plastic raw material, ELANT Technicians will study and analysis the main contaminants to provide a proper solution to remove most of the impurities by mechanical, chemical, physical and other principle.

>>Main process of whole project including pretreatment of raw material → crushing → washing → drying → package → granulation.

1) Belt conveyor feeding

>>Belt conveyor is as a standard feeding device for plastic film, raffia, filament, woven bag, nonwoven fabric, etc.

>>Screw conveyor and Nip roller as optional feeding method designed for different type of materials. ²

>>Metal detector can be installed on conveyor as optional item, Detecting and separating the metal to protect shredder or crusher effectively.

2) Crusher machine

>>GH series Granulator /Crusher can process Film, bags, Bottle, containers and other form of hollow thin walled plastics. It is equipped a 500-800mm diameter, 700-2000mm width rotor with a capacity range 100-5500kg/h.

>>It has a centrally hinged two-pieces cutting chamber with a robust welded steel construction, with the upper and lower sections of the housing meeting horizontally.

>>Reversible stator knives with double cutting edges are fitted as single elements to the lower section of the housing, allowing multiple re-sharpening and adjustment of the stator knives.

3) Friction washer & Screw loader

>>It is mainly used for strong friction cleaning, adopting spiral blade structure, medium and low speed friction principle to reduce or remove the adhesion of contaminants to the material.

>>Centrifugal the contaminants onto the screen, and adding clear water removes the sediment on the material through the centrifugal action during the operation, and clean the materials efficiently.

4) Floating washer

>>The flotation washer for cleaning size reduced plastic film scraps, by rotary paddles and water, which can remove most of the dust, sands, sludge, soil and other sink contaminants.

>>The main principle is to use the specific gravity of water, specializing in the initial wash and rinse of submerged and floating materials, it can effectively separate the sediment and metal in the material. The system will discharge the sink contaminants, such as sands, sludge, sink plastic, metals through the pneumatic bottom valves automatically. It will ensure the good washing condition of water.

5) Dewatering machine /Centrifugal drier

>>It is mainly used for removing moisture from the film/bags and other soft material. It can efficiently remove the humidity from soft plastic materials.

>>The equipment adopts centrifugal force to dry materials. To reduce the moisture content of the material to below 7% without melting.

6) Silo

>>It is mainly stored materials, the silo sizes can be tailor-made with a volume from 1-10CBM, which is mainly made by stainless steel.

Audited supplier

Audited supplier

Best HDPE rigid plastic pelletizing machine Supplier

China PPR Pipe Shredder Machine EL-P800 manufacturers -

China LDPE film washing recycling machine 800-1000kghr manufacturers -

PE film recycling pelletizer machine 500kghr

LDPE LLDPE HDPE Film Plastic Pelletizing Machine Supplier

Plastic PP PE rigid flakes recycling granulating machine

PP PE squeezed films recycling pelletizing machine

HDPE PP rigid plastics strand recycling pelletizing machine

PP woven bags, non woven fabric, raffia recycling granulating machine