China PET bottle recycling washing machine line manufacturers-Elant

China manufacturer ELANT supplied high quality PET plastic bottle recycling washing machine line for Argentina customer 1500-2000kg/hr.

Elant China PET bottle recycling washing machine line manufacturers-Elant,High Quality Plastic Recycling Machine with Competitive Price.

Audited supplier

Audited supplierApplication:

PET waste bottles recycling and washing line is a complete solution designed for the waste PET bottles, such as mineral water bottles, cola bottles, pesi bottles etc. The PET washing line including label-removing, crushing, washing, drying and packing; it is the perfect system to process the waste bottles into PET flakes, which can present high quality performance of recycled PET flakes.

And then the clean PET flakes will be used for polyester stable fibre, strap, filament, sheet, films and even bottle-bottle grade.

Working process of plastic PET bottle recycling washing line:

Feeding & debaler – Dry separation – Delabler – Hot/cold pre-washer –Automatic and manual sorting – Wet grinding – Hot washer – Sink/float separation – Rinsing- Drying – Fines separation – Flakes sorting – Blending – Storage and Packaging.

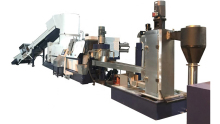

Photos of PET bottle washing line:

|  |

Technical data of PET bottles washing recycling machine:

No. | Production capacity (Kg/hr) | Total installation power (Kw) | Water consumption (M3/H) | Line size (mm): | Workers |

1 | 300-500kg/hr | 70-125 | 3-5 | 45*5*5 | 3-6 |

2 | 1000-1500kg/hr | 359 | 5-8 | 75*6*5m | 6-10 |

3 | 2000kg/hr | 445 | 8-10 | 106*6*5.8m | 10-12 |

4 | 3000kg/hr | 638 | 10-12 | 132*7*6.5m | 16-20 |

Above date is only for reference. We design pet bottle recycling line according to different raw material and above date will be different.

Advantages of Plastic PET bottles recycling machine:

1. Final products have good quality. When process PET bottle, final products humidity below 1%, impurities 100ppm, PVC label content 100ppm.

2. Parts which contact material use SUS304 stainless steel, thickness more than 3mm, ensure long service lift time and no second pollution to flakes.

3. World famous brand components applied on the production line- NSK bearing, Siemens contactor, Omron temperature, FUJI inverter, Siemens PLC control etc.

4. Friendly control system (PLC integrated & separated control on each machine) and Touch screen panel, easy for operation, monitor and emergency stop.

5. The whole production equipment is researched, design and manufactured by our company with CE certification, ISO9001 certification; it can be designed based on the dirty flakes, and make sure of the quality of the final products.

Spec of end PET flakes/chips products from PET bottle washing line:

Intrinsic Viscosity (IV) (dl/g) | 0.65-0.76 (depends on raw materials) | |

Melt point (℃) | 252-260 | |

Moisture | 0.5-2% | |

Bulk density (kg/m3) | 280-450 | |

Particle size (mm) | 3-14 | |

Fraction | 1-3mm | 8-15% |

≤1mm | Max. 2% | |

PH Value | Max. 9 | |

PVC (ppm) | Max. 100 (based on raw material & design) | |

PE/PP (ppm) | Max. 50 | |

Paper (ppm) | Max. 10 | |

Glue (ppm) | Max. 10 | |

Metal (ppm) | Max. 10 | |

Other organics (ppm) | Max. 100 | |

About Elant

Audited supplier

Audited supplier

Best HDPE rigid plastic pelletizing machine Supplier

China PPR Pipe Shredder Machine EL-P800 manufacturers -

China LDPE film washing recycling machine 800-1000kghr manufacturers -

PE film recycling pelletizer machine 500kghr

LDPE LLDPE HDPE Film Plastic Pelletizing Machine Supplier

Plastic PP PE rigid flakes recycling granulating machine

PP PE squeezed films recycling pelletizing machine

HDPE PP rigid plastics strand recycling pelletizing machine

PP woven bags, non woven fabric, raffia recycling granulating machine