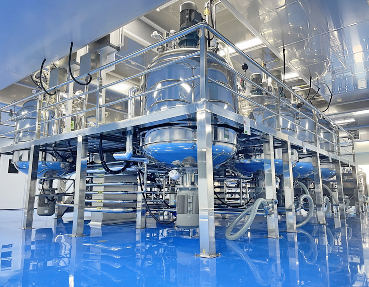

Customized industry cosmetic paste liquid soap production line homogenizer mixer tank PLC control stirring reactor

Blender is suitable for the production of various types of detergents, cosmetics, spices and other fine chemicals necessary equipment

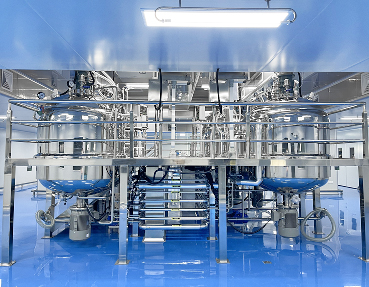

◭The all-round wall scraping mixing adopts the frequency converter for speed adjustment , so that high quality products ofdifferent processes according to customer requirements.

◭The diversified high-speed homogenizer can powerfully mix solid and liquid raw materials and can rapidly dissolve manyindissoluble materials such as AES , AESA , LSA , etc. during the liquid detergent production process so as to save energy consumpion and shorten production period.

◭The pot body is welded by imported three-layer stainless steel plate. The tank body and the pipes adopt mittor polishing , which fully conforms to GMP requirements.

◭According to customer requirement , the tank can heat and cool materials. The heating way including steam heating and electric heating. Easy to discharge , bottom direct discharge or by transfer pump.

Audited supplier

Audited supplier| Model | Effective Capacity | Stirring power and speed | Homogeneous power and speed | Heating mode | |||

| KW | r/min | KW | r/min | Electric heating | Steam heating | ||

| GY-50 | 50 | 0.75 | 0-65 | 3 | 3500 | 6kw | Steam heating enerayconservation and environment al protection,selected according to need. |

| GY-100 | 100 | 1.5 | 0-65 | 1.5 | 3300 | 12kw | |

| GY-150 | 150 | 1.5 | 0-65 | 1.5 | 3300 | 12kw | |

| GY-200 | 200 | 1.5 | 0-65 | 3 | 3000 | 18kw | |

| GY-300 | 300 | 1.5 | 0-65 | 3 | 3000 | 18kw | |

| GY-500 | 500 | 2.2 | 0-65 | 4 | 3000 | 27kw | |

| GY-1000 | 1000 | 4 | 0-65 | 7.5 | 3000 | 36kw | |

| GY-1500 | 1500 | 4 | 0-65 | 11 | 3000 | 45kw | |

| GY-2000 | 2000 | 5.5 | 0-65 | 11 | 2500 | Recommended sandwich seam heating | |

| GY-3000 | 3000 | 7.5 | 0-65 | 15 | 1500 | ||

| GY-5000 | 5000 | 11 | 0-65 | 22 | 1500 | ||

| Note: The parameters on this form are for reference only, and the actual product shall prevail | |||||||

Features

———————————

The combined pot mixer production line integrates the functions of mixing, homogenization, heating, cooling, pumping and defoaming .

(All functions can be customized according to the situation)

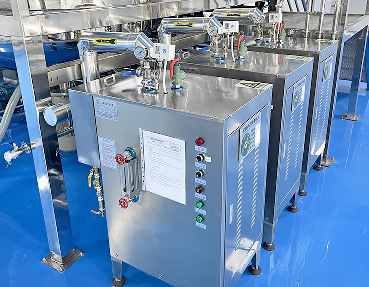

Control Panel

——————————

The control panel displays and controls the equipment temperature, mixing, homogenization, pressure data, etc. in real time(real-time grasp of equipment conditions to achieve safe production)

Heating

————————————

Using steam heating method, simple operation, fast heating speed and resource saving

Results

————————————

Use frequency conversion speed control mixing and omogeneousshearing to mix and react the materials, So as to get high-quality products

Audited supplier

Audited supplier

500L vacuum mixer tank gel making machine Vaseline resin reactor stir blender Alcohol fermentation tank

Customized industry cosmetic paste liquid soap production line homogenizer mixer tank PLC control stirring reactor

Customized 1000ml 1500ml oil gel cream 12 nozzles automatic filling capping line liquid detergent packing machine

Oral perfume Mouthwash Liquid medicine fully automatic filling capping sealing machine botte packing line equipment

cosmetic liquid detergent production line gel cream paste stirring homogenizer blender mixer tank

1000L customized combine homogenizer mixing tank shampoo liquid hand soap stirring vessel making equipment

Guanyu 12 Nozzles Full Automatic Electric Honey Shampoo Laundry Detergent Liquid Bottle Filling Capping Machine

Guanyu New Arrival Automatic Plc Honey Filling and Capping Machine Liquid Soap Hand Wash Piston Filler

High Quality Self priming Double Head Filling Machine Manufacturer | GUANYU