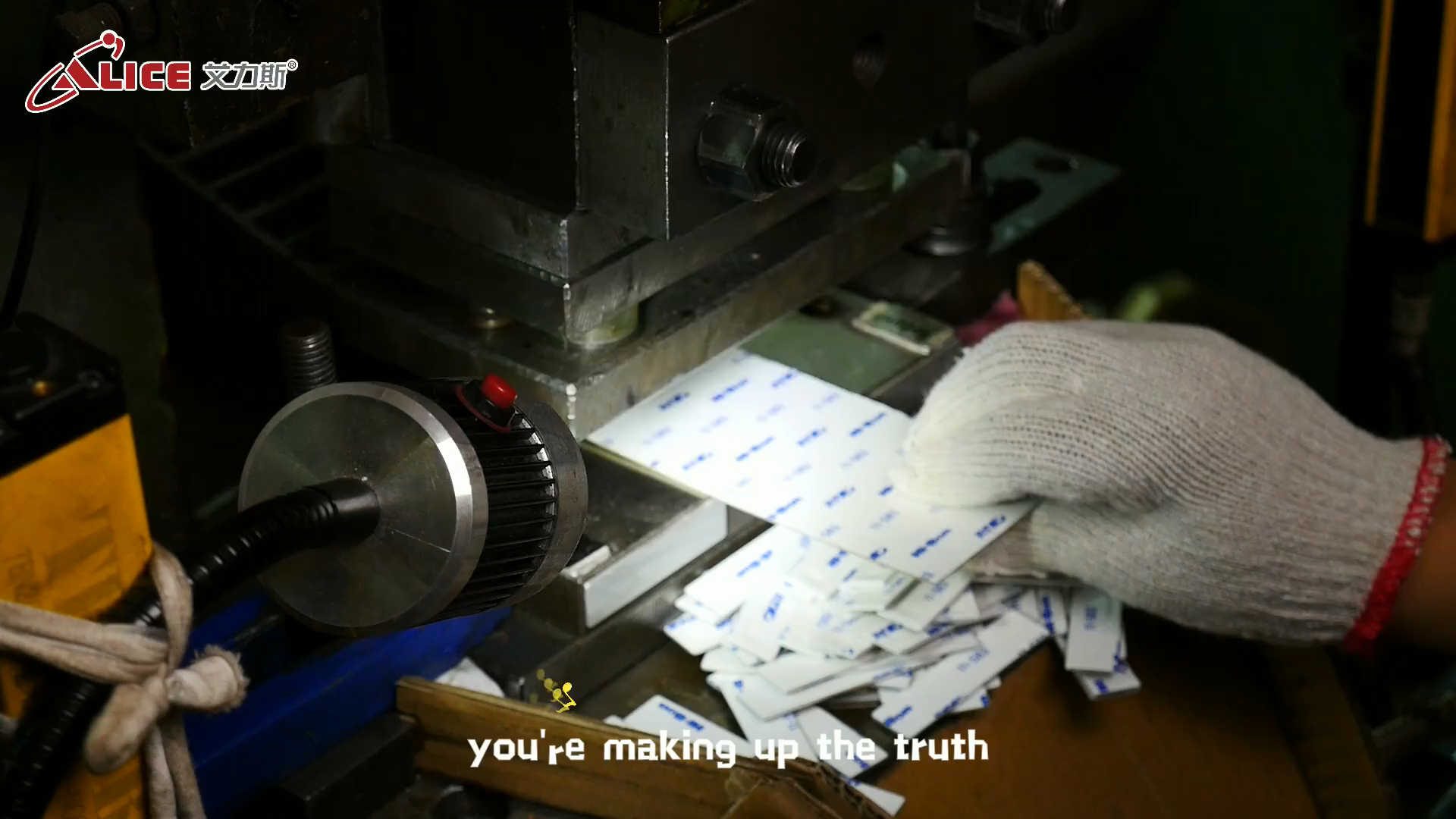

Customized processing of metal signs, stamping production process of signs-Alice factory

The principle of the stamping machine is to drive the flywheel through the motor, and through the clutch and transmission gear to drive the crank and connecting rod mechanism to move the slider up and down, and to drive the drawing die to form the steel plate. The so-called double action means that the press has two sliders, which are divided into an inner slider and an outer slider. The inner slider drives the punch or die of the mold, and the outer slider drives the blank holder ring on the mold. At the same time, the blank holder first moves to press the edge of the steel plate, and then the inner slide moves to stretch. In fact, what we call a punching machine is a common name, which is what we often call a punching machine. The scientific name should be called press.

Audited supplier

Audited supplier1、The principle of the punching machine: the flywheel is driven by the electric motor, and the crank connecting rod mechanism is driven by the clutch and the transmission gear to move the slider up and down, and the drawing mold is driven to form the steel plate. The so-called double action means that the press has two sliders, which are divided into an inner slider and an outer slider. The inner slider drives the punch or die of the mold, and the outer slider drives the blank holder ring on the mold. At the same time, the blank holder first moves to press the edge of the steel plate, and then the inner slide moves to stretch.

The design principle is to convert circular motion into linear motion. The main motor generates power to drive the flywheel. The clutch drives the gear, crankshaft (or eccentric gear), connecting rod, etc., to achieve the linear motion of the slider, from the main motor to the connecting rod. The movement of is a circular movement.

The connecting rod and the sliding block need to have a circular motion and a linear motion transition point. There are roughly two mechanisms in the design, one is a ball type, the other is a pin type (cylindrical type), through which the circular motion is moved Converted into linear motion of the slider. The stamping machine applies pressure to the material to deform it plastically to obtain the required shape and precision. Therefore, it must be matched with a set of molds (upper mold and lower mold), the material is placed in between, and the machine applies pressure to make it Deformation, the reaction force caused by the force applied to the material during processing, is absorbed by the mechanical body of the punching machine.

2、Classification of stamping machines: according to different driving forces, according to the sliding block driving mechanism, according to the form of the body

3、Maintenance and maintenance: the processing accuracy of the punching machine and the gap between the slider and the slide rail (generally standard comprehensive gap 0.02~0.13) and the deformation of the body of the punching machine during operation (especially the center line of the slider for the C-type punching machine) The standard of working deviation from the center line of the worktable is not more than 3), the parallelism between the lower plane of the slider and the worktable surface, the gap between the slider and the connecting rod of the slider, the gap between the slider connecting rod and the crankshaft, and the flywheel The center of the vibration is related.

According to the above points, it should be reflected in the daily/time inspection and annual inspection of the press. In addition, the content related to these inspection items should also be reflected in the daily inspection. For example: oil condition, noise, vibration, body shaking, 2S and so on.

Contact us E-mail: sales03@alicelogo.com

Audited supplier

Audited supplier

Factory workshop introduction (6)

Zinc alloy metal engraving nameplate-Alice

Metal aluminum wine bottle label display-Alice

Zinc alloy furniture nameplates can be customized processing-Alice

Metal aluminum wine bottle label display-Alice

Electroformed nickel label, metal patch, metal sign customization, thin and beautiful, easy to stick

Zinc alloy nameplate metal label is affordable and can be processed and customized-Alice factory

Different materials can be laser carved in different colors-Alice factory

Factory workshop introduction (8)-Automatic punching machine-Alice