Factory workshop introduction (8)-Automatic punching machine-Alice

Factory workshop introduction (8)-Automatic drilling machine a machine that combines a small computer and punching machine

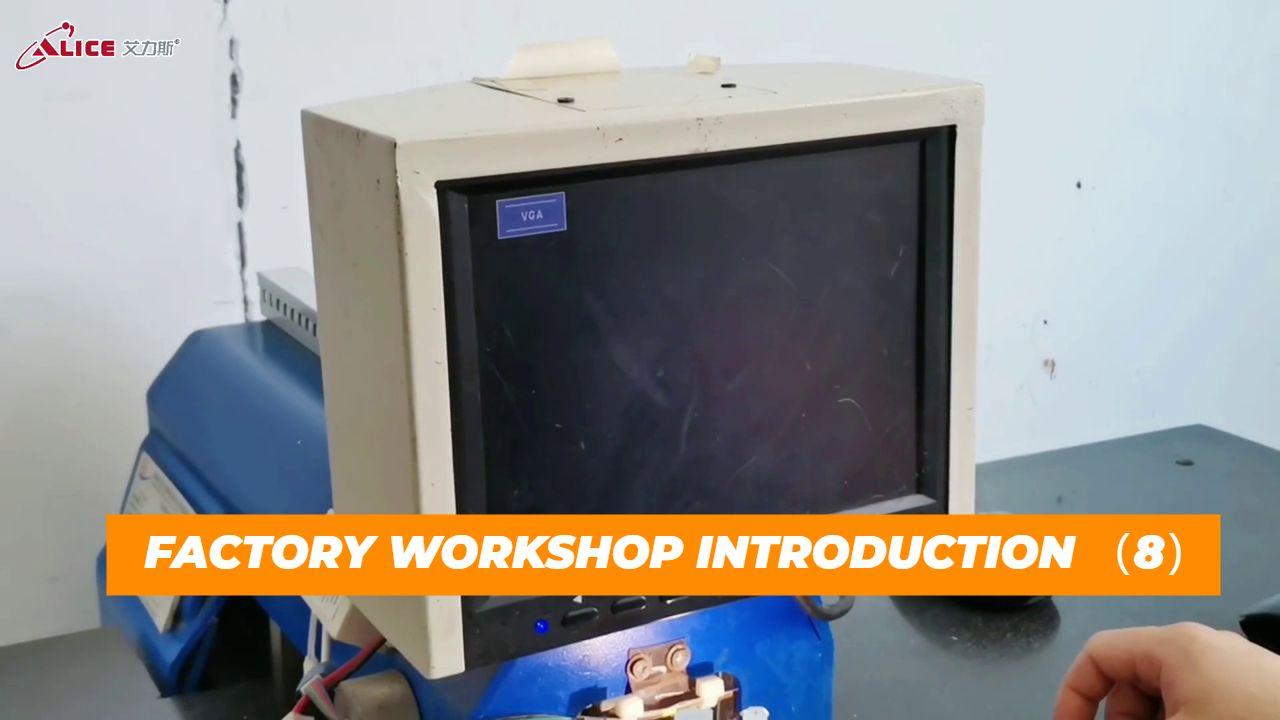

Automatic drilling machine,This is a machine that combines a small computer and punching machine.

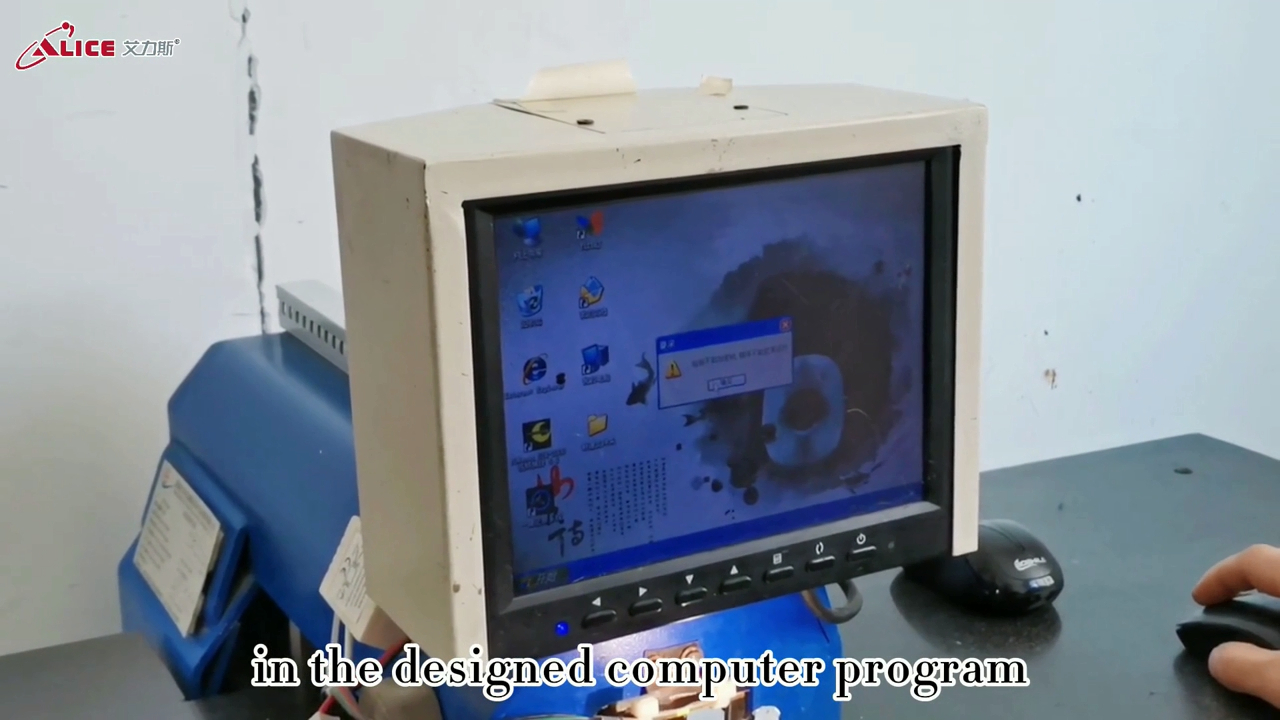

First of all, when we design the drawings, the style and size of all the positioning holes are almost the same,Then select the positioning hole in the designed computer program,Choose automatic stamping,As long as the positioning hole icon appears in the screen, the machine will automatically punch holes,Very convenient, fast and accurate positioning,The size of the punching diameter can also be achieved by replacing the punching needle

Audited supplier

Audited supplierThe punching machine is composed of four parts that cooperate with each other to complete the punching process. First, move the material to the scanning area of the camera of the automatic punching machine. After the camera scans the image, it will process and give the control part a signal. After the control part receives the signal, it will further process and control the movement of the transmission part to make the punch on the plane X Axis and Y-axis are moving. After the moving action is completed, the pneumatic part starts to work, and the solenoid valve controls the cylinder to perform the punching action. The automatic punching machine punches printing positioning holes, and the whole action is done in one go, fast, accurate and efficient.

Punching machine classification:

Divided by category: pearl punching machine, laser punching machine, automatic punching machine, electric punching machine, manual punching machine, plastic bag punching machine, pneumatic punching machine, non-woven punching machine.

According to the number of holes: single-hole punching machine, 2-hole punching machine, 3-hole punching machine, 4-hole punching machine.

Punching machine accessories: punching pads, punching knives, punching needles, punching pads, punches.

Advantages of punching machine classification:

1. Working speed: up to 130 times per minute (2-3MM/each time)

2. APM-380: The maximum punching width is 380MM; the maximum punching width of APM-600 is 600MM. APM-380 is suitable for processing stationery products; APM-600 is suitable for punching processing of stationery, desk calendars, wall calendars, etc., belonging to the general industry

3. Various molds can be replaced

4. Using high-quality electronic control originals, stable performance and convenient operation

5. Multiple safety protection devices to ensure the safety of operators, can extend its applicable life and reduce product loss

6. The machine parts are processed by CNC computer numerical control machine tools, produced in batches, and have stable performance.

Audited supplier

Audited supplier

Factory workshop introduction (6)

Zinc alloy metal engraving nameplate-Alice

Metal aluminum wine bottle label display-Alice

Zinc alloy furniture nameplates can be customized processing-Alice

Metal aluminum wine bottle label display-Alice

Electroformed nickel label, metal patch, metal sign customization, thin and beautiful, easy to stick

Zinc alloy nameplate metal label is affordable and can be processed and customized-Alice factory

Different materials can be laser carved in different colors-Alice factory

Factory workshop introduction (8)-Automatic punching machine-Alice