Professional Automatic Security Traffic Hydraulic Bollard with Good Price Manufacturer--Zento

Zento Bollard series Hydraulic Retractable Bollards are designed for high security vehicle entrances, military, industrial, governmental and commercial buildings or streets which are closed to vehicle traffic between certain hours of the day.

The drive unit is hydraulic, but in case of power failure Hydraulic bollard can be lowered or lifted manually with the help of manual hand pumps. With the help of PLC controlled electronics, raise/lower function can be achieved by every kind of card readers, biometric readers like fingerprint or hand shape, radio control, on/off key switch etc. Besides, safety accessories like photocells, inductive loop detectors, flashing lights or red/green lights can be integrated to the Hydraulic Bollard system.

Audited supplier

Audited supplierHydraulic Bollard Movement: The most reliable technology for intense temperatures and weather conditions.

Built–in hydraulic pump in the bollard: These automactic hydraulic bollards have many advantages, particularly in installations on locations with severe winter temperatures or when the installation requires a considerable distance (up to 80 meters) between the Bollard and the control unit.

Patented system for the protection of handling: To maximize the reliability of operations due to impact by vehicles on the cylinder that is put in motion.

Wide range of optional configurations: Custom colors, flashing lights integrated into the head, intermittent sound signal, heat resistance installations in locations with harsh winter temperatures,UPS unit for operation in the temporary occurrence of power failure, equipment control, equipment accident prevention (see accessories and optional items).

| Height when raised | 400-1200 mm |

| Environmental durability | 316 stainless steel sleeve, underground parts are hot dip galvanized |

| Axle load | 50 tons |

| Structure | Heavy duty |

| Top plate | Sand blasted aluminum with flashing light around |

| Type of steel | S275 (inner core), finishing 316 stainless steel sleeve |

| Traffic light | Red/green LED, 200 mm diameter, steel post 2 m height and electrostatic powder coated |

| Power | 380 V, 3 Phase, 50-60 Hz (or 220 V/ 440 V etc., three phase, 50-60 Hz optional by a transformer) |

| Power failure | Manual hand pump, (or Hydraulic accumulator, DC motor and batteries or UPS (optional) |

| Speed | From 1 bollard to 4 bollards per hydraulic unit: 3-5 s (1.5 s Emergency Raise) |

| From 5 bollards to 6 bollards per hydraulic unit: 5-7 s (2 s Emergency Raise) | |

| From 7 bollards to 8 bollards per hydraulic unit: 8-12 s (3 s Emergency Raise) | |

| Desktop keyboard | Raise, lower, emergency stop, key operated, ‘keyboard in use’ light indicator |

| Extra I/O at the PLC | Enough I/O’s to connect any card reader, extra override keyboard etc. later on |

| Proximity Sensor | Available to sense the position of the bollard |

| Dual vehicle safety loop detector | This detector is used for safety |

| Motor Power | Min 4 KW, 1500 rpm |

Environmental conditions | -25 °C and +65 °C, %95 non-condensing humidity |

| Environmental conditions (optional) | -40 °C and +70 °C, %95 non-condensing humidity |

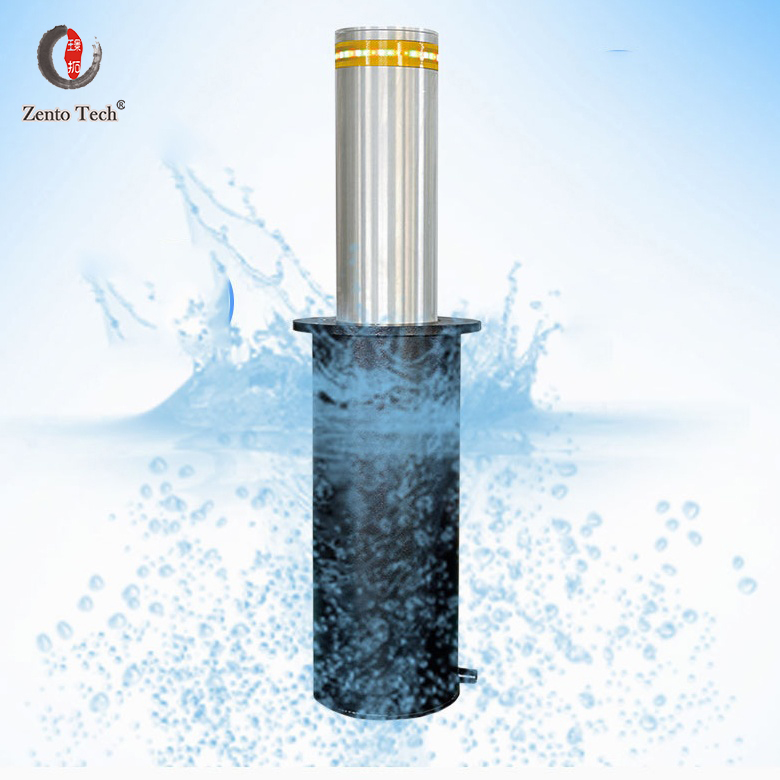

304 stainless steel

Cylinder, wear-resistant and corrosion-resistant, the surface can be polished with 4K mirror. 304 stainless steel material, corrosion resistant and durable

Hydraulic bollard using a better waterproof motor, tested by immersior operation and leaving the factory,the deep waterproof shell adapts to various harsh environments safe and safe to use.

Hydraulic Bollard

Strong reflective film. The effect of the reflective film is good, and the night visibility of the 3M reflective strip ensures that the reflective light can play a good warning role, and LED 1ights can also be installed

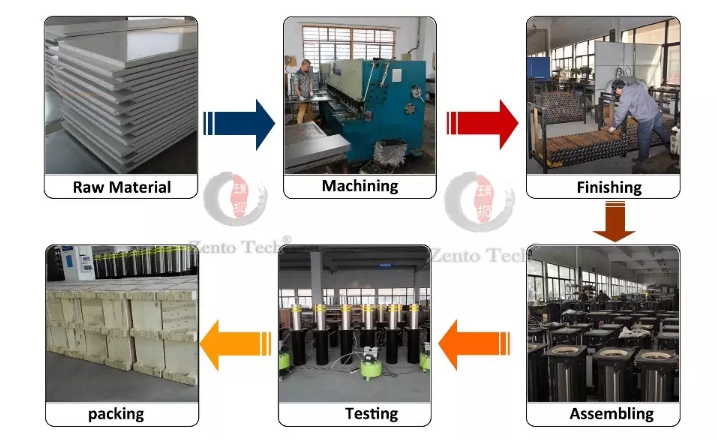

The installation of the hydraulic lifting column is simple. We will have an installation manual or a video. Our technical staff can provide remote technical guidance, installation guidance and timely answers to technical questions. Our sales staff will help you online 24 hours a day.

- Gina Li

- Shenzhen Zento Traffic Equipment Co., Ltd.

Send Inquiry

Audited supplier

Audited supplier

Entrance Automatic Security Small Swing Turnstile Barrier Gate Speed Gate Swing Barrier Turnstile with Access Control

Automatic Outdoor Optical Face Recognition Swing Turnstile Barrier Gate System

Fingerprint Subway Slim Brazil Case 2 Years Swing Turnstiles Opener Supermarket Barrier

Automatic Turnstiles High Speed Glass Door Swing Barrier Gate turnstile

Automatic Turnstiles High Speed Glass Door Swing Barrier Gate turnstile Factory

Speed Gates Price Digital Face Recognition 4 Inch Access Control Turnstile Gates High Speed Gate Turnstile Price

Finger Print Reader Entrance Control Sliding Barrier Automated Entrance Gym Membership Turnstile

Automatic Access Control Entrance Barrier Gate Sliding Turnstile Price

Access Control Tripod Turnstile Gate with Counter / Tripod Turnstile Parts / Automatic Tripod Turnstile Gate