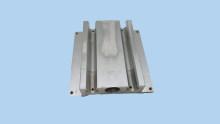

OEM Custom Aluminum Alloy Die Casting LED Lighting Housing

2 years ago

372

Share

First of all, let me analyze the uses and characteristics of aluminum alloy die-casting products in the die-casting industry. Die casting is a kind of precision casting method that uses high pressure to melt metal into complex metal mold. In 1964, Japan Die Casting Association defined die casting as "pressing molten alloy into precision mold at high temperature and mass producing high-precision and excellent casting surface in a short time". Die casting is called die casting in the United States and pressure die casting in the United Kingdom. What is most familiar to ordinary domestic operators is the Japanese saying, which is called die casting. Castings made by die casting are called die castings.

The advantages of aluminum alloy die-casting lamp shell are listed in detail below:

1.LED lamps need materials with good heat dissipation, and the thermal conductivity of aluminum is much larger than that of steel; It can dissipate heat, prevent water and dust. In addition, the surface of LED lamps has been treated with UV resistance and corrosion resistance. Aluminum alloy die-casting material is solid and light, with high hardness, which reduces the weight and makes the lamps more safe and reliable.

2.In terms of thermal conductivity, aluminum alloy die casting material is second only to silver, copper and gold. Gold and silver are too expensive. Copper weight is a problem. Aluminum is the best choice. There is a dense layer of alumina on the aluminum surface, which has a good anti-oxidation and corrosion effect. There is a passivation layer on the surface of aluminum alloy die casting material, which can prevent the external corrosion of aluminum alloy. If it is used in outdoor environment, The service life of the lamp is greatly increased. For die castings, compared with magnesium alloy, the weight is heavier, the rigidity is not as strong as magnesium alloy, and the cost is almost the same.

3.With good heat dissipation design, how to make the life and light output quality of the chip in the best state has become the top priority that lamp manufacturers need to consider. Each chip has anode temperature, which should be controlled within 85 ° C, so that the chip can ensure the best working state. How to ensure the heat from the chip, aluminum substrate, heat conducting material to the radiator, The heat can be transferred smoothly and efficiently to the surrounding environment. In addition to the careful design of die-casting lamps by engineers, the material selection and process treatment of each link should be carefully considered and tested to achieve the best working state.

Our company can customize according to your demand, like mechanical parts processing, CNC aluminum products processing, CNC aluminum processing, CNC precision machining, CNC processing customization and etc . Then mass production of samples and rapid production of samples. We guarantee high quality and high precision. The precision aluminum profile tolerance can reach ±0.02MM.

The advantages of aluminum alloy die-casting lamp shell are listed in detail below:

1.LED lamps need materials with good heat dissipation, and the thermal conductivity of aluminum is much larger than that of steel; It can dissipate heat, prevent water and dust. In addition, the surface of LED lamps has been treated with UV resistance and corrosion resistance. Aluminum alloy die-casting material is solid and light, with high hardness, which reduces the weight and makes the lamps more safe and reliable.

2.In terms of thermal conductivity, aluminum alloy die casting material is second only to silver, copper and gold. Gold and silver are too expensive. Copper weight is a problem. Aluminum is the best choice. There is a dense layer of alumina on the aluminum surface, which has a good anti-oxidation and corrosion effect. There is a passivation layer on the surface of aluminum alloy die casting material, which can prevent the external corrosion of aluminum alloy. If it is used in outdoor environment, The service life of the lamp is greatly increased. For die castings, compared with magnesium alloy, the weight is heavier, the rigidity is not as strong as magnesium alloy, and the cost is almost the same.

3.With good heat dissipation design, how to make the life and light output quality of the chip in the best state has become the top priority that lamp manufacturers need to consider. Each chip has anode temperature, which should be controlled within 85 ° C, so that the chip can ensure the best working state. How to ensure the heat from the chip, aluminum substrate, heat conducting material to the radiator, The heat can be transferred smoothly and efficiently to the surrounding environment. In addition to the careful design of die-casting lamps by engineers, the material selection and process treatment of each link should be carefully considered and tested to achieve the best working state.

Our company can customize according to your demand, like mechanical parts processing, CNC aluminum products processing, CNC aluminum processing, CNC precision machining, CNC processing customization and etc . Then mass production of samples and rapid production of samples. We guarantee high quality and high precision. The precision aluminum profile tolerance can reach ±0.02MM.

Comments

No comments received

Suppliers

Guangdong Aluminum Application Precision Technology Co., Ltd.

Audited supplier

Audited supplierChina3YRS

Road 5, Jihua Road, Chancheng District, Foshan City, Guangdong Province, China

Product details

Comments

Suppliers

Guangdong Aluminum Application Precision Technology Co., Ltd.

Audited supplier

Audited supplierChina3YRS

Road 5, Jihua Road, Chancheng District, Foshan City, Guangdong Province, China

You may also like

AL Aluminum丨OEM Aluminum Extrusion Aluminium Heat Sink High Precision Quality Cylindrical Sun Flower Aluminum Heat Sink

Ali Home Video

Custom Precision Led Aluminum Profile Radiator LED Sunflower Aluminum Profile Radiator

High Precision Quality Industrial Aluminum Alloy Electric Heating Towel Rack Bracket Aluminum Profile

High Precision Quality Customized Laser Marking Machine Aluminum Profile

High End Precision Quality Jewelry Showcases Aluminum Profiles Parts Cases Frame

OEM Custom Aluminum Alloy Die Casting LED Lighting Housing

High Precision Quality Cylindrical Sun Flower Aluminum Heat Sink Led Aluminum Profile

Aluminum Alloy Panel Customized Stamping Processing Customized Aluminum Alloy Keyboard Base