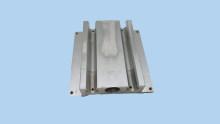

High Precision Quality Customized Laser Marking Machine Aluminum Profile

2 years ago

358

Share

How is the laser marking machine applied to aluminum?

The original inkjet printer could not provide permanent marks on aluminum products and could not carry out effective anti-counterfeiting work. The logo has been put into the market with good feedback. The anti-counterfeiting work is greatly reduced. So how is it applied to aluminum?

The powder spraying line shall be marked by laser. Considering that the powder spraying layer is thick and the mark is seriously covered, the mark is not clear. Increasing the power mark will seriously affect the service life of semiconductors. Lengthening the marking time will seriously affect the production efficiency. For this phenomenon, our company proposes two solutions:

Scheme I. our company suggests marking with semiconductor YAG after powder spraying.

Because it can be seen under a high magnification microscope that there is no damage to the powder layer by using a semiconductor YAG laser marking machine. This is the photochemical reaction between the YAG wavelength laser and the powder layer, which only changes the color. Therefore, our company suggests using semiconductor YAG laser marking machine to mark after powder spraying, because the current can be controlled at about 12a (at present, the marking current of electrophoretic materials and oxidized materials is about 18a), which can greatly prolong the service life of semiconductor modules, greatly reduce the maintenance rate of equipment, shorten the time to about 1s, and greatly improve the production beat.

Scheme 2: our company suggests marking with CO2 laser marking machine after powder spraying.

Under the high magnification microscope, it can be seen that the powder layer is damaged by CO2 laser marking machine, which is the result of CO2 wavelength laser burning the powder layer. However, because the laser energy can be controlled, the damage depth can be controlled within the range that does not affect the profile. This conclusion is verified by pitting test (simulating natural acid-base corrosion in the laboratory). Therefore, we suggest to use CO2 after powder spraying. First, the damage to the coating can be controlled within an acceptable range by controlling the laser energy. The second time can be shortened to about 1 second, greatly improving the production beat. III. The imported CO2 laser is a fully sealed maintenance free product, and the air cooling of the equipment is free of water cooler, which greatly reduces the maintenance rate of the equipment. Fourth, 30W or even 10W CO2 imported lasers can be used, greatly reducing the equipment price.

For marking on electrophoretic materials or oxidized materials, at present, 50W semiconductor laser marking machine can also successfully complete the task. However, in order not to affect the service life of semiconductor laser module in the user's environment and meet the user's requirements for clearer marking effect, I suggest using 100W semiconductor is better. If you want to obtain a more detailed solution, please consult our company.

The advantages of aluminum profile are as follows:

Corrosion resistance :The density of aluminum profile is only 2.7g/cm3, about 1 / 3 of that of steel, copper or brass (7.83g/cm3 and 8.93g/cm3 respectively). Aluminum shows excellent corrosion resistance under most environmental conditions, including air, water (or brine), petrochemical and many chemical systems.

Conductivity:Aluminum profile is often selected because of its excellent conductivity. On the basis of equal weight, the conductivity of aluminum is nearly 1 / 2 of that of copper.

Thermal conductivity:The thermal conductivity of aluminum alloy is about 50-60% of that of copper, which is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, as well as automobile cylinder heads and radiators.

Non ferromagnetism:Aluminum profile is non ferromagnetic, which is an important characteristic for electrical industry and electronic industry. Aluminum profiles cannot spontaneously ignite, which is important for applications involving handling or contacting flammable and explosive materials.

Machinability:The machinability of aluminum profile is excellent. In various deformed aluminum alloys and cast aluminum alloys, as well as in various states after the production of these alloys, the machining characteristics change greatly, which requires special machine tools or technologies.

Formability:The variation of allowable deformation is dominated by specific tensile strength, yield strength, ductility and corresponding work hardening rate.

Recyclability:Aluminum has high recyclability, and the characteristics of recycled aluminum are almost the same as that of primary aluminum.

The original inkjet printer could not provide permanent marks on aluminum products and could not carry out effective anti-counterfeiting work. The logo has been put into the market with good feedback. The anti-counterfeiting work is greatly reduced. So how is it applied to aluminum?

The powder spraying line shall be marked by laser. Considering that the powder spraying layer is thick and the mark is seriously covered, the mark is not clear. Increasing the power mark will seriously affect the service life of semiconductors. Lengthening the marking time will seriously affect the production efficiency. For this phenomenon, our company proposes two solutions:

Scheme I. our company suggests marking with semiconductor YAG after powder spraying.

Because it can be seen under a high magnification microscope that there is no damage to the powder layer by using a semiconductor YAG laser marking machine. This is the photochemical reaction between the YAG wavelength laser and the powder layer, which only changes the color. Therefore, our company suggests using semiconductor YAG laser marking machine to mark after powder spraying, because the current can be controlled at about 12a (at present, the marking current of electrophoretic materials and oxidized materials is about 18a), which can greatly prolong the service life of semiconductor modules, greatly reduce the maintenance rate of equipment, shorten the time to about 1s, and greatly improve the production beat.

Scheme 2: our company suggests marking with CO2 laser marking machine after powder spraying.

Under the high magnification microscope, it can be seen that the powder layer is damaged by CO2 laser marking machine, which is the result of CO2 wavelength laser burning the powder layer. However, because the laser energy can be controlled, the damage depth can be controlled within the range that does not affect the profile. This conclusion is verified by pitting test (simulating natural acid-base corrosion in the laboratory). Therefore, we suggest to use CO2 after powder spraying. First, the damage to the coating can be controlled within an acceptable range by controlling the laser energy. The second time can be shortened to about 1 second, greatly improving the production beat. III. The imported CO2 laser is a fully sealed maintenance free product, and the air cooling of the equipment is free of water cooler, which greatly reduces the maintenance rate of the equipment. Fourth, 30W or even 10W CO2 imported lasers can be used, greatly reducing the equipment price.

For marking on electrophoretic materials or oxidized materials, at present, 50W semiconductor laser marking machine can also successfully complete the task. However, in order not to affect the service life of semiconductor laser module in the user's environment and meet the user's requirements for clearer marking effect, I suggest using 100W semiconductor is better. If you want to obtain a more detailed solution, please consult our company.

The advantages of aluminum profile are as follows:

Corrosion resistance :The density of aluminum profile is only 2.7g/cm3, about 1 / 3 of that of steel, copper or brass (7.83g/cm3 and 8.93g/cm3 respectively). Aluminum shows excellent corrosion resistance under most environmental conditions, including air, water (or brine), petrochemical and many chemical systems.

Conductivity:Aluminum profile is often selected because of its excellent conductivity. On the basis of equal weight, the conductivity of aluminum is nearly 1 / 2 of that of copper.

Thermal conductivity:The thermal conductivity of aluminum alloy is about 50-60% of that of copper, which is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, as well as automobile cylinder heads and radiators.

Non ferromagnetism:Aluminum profile is non ferromagnetic, which is an important characteristic for electrical industry and electronic industry. Aluminum profiles cannot spontaneously ignite, which is important for applications involving handling or contacting flammable and explosive materials.

Machinability:The machinability of aluminum profile is excellent. In various deformed aluminum alloys and cast aluminum alloys, as well as in various states after the production of these alloys, the machining characteristics change greatly, which requires special machine tools or technologies.

Formability:The variation of allowable deformation is dominated by specific tensile strength, yield strength, ductility and corresponding work hardening rate.

Recyclability:Aluminum has high recyclability, and the characteristics of recycled aluminum are almost the same as that of primary aluminum.

Comments

No comments received

Suppliers

Guangdong Aluminum Application Precision Technology Co., Ltd.

Audited supplier

Audited supplierChina3YRS

Road 5, Jihua Road, Chancheng District, Foshan City, Guangdong Province, China

Product details

Comments

Suppliers

Guangdong Aluminum Application Precision Technology Co., Ltd.

Audited supplier

Audited supplierChina3YRS

Road 5, Jihua Road, Chancheng District, Foshan City, Guangdong Province, China

You may also like

AL Aluminum丨OEM Aluminum Extrusion Aluminium Heat Sink High Precision Quality Cylindrical Sun Flower Aluminum Heat Sink

Ali Home Video

Custom Precision Led Aluminum Profile Radiator LED Sunflower Aluminum Profile Radiator

High Precision Quality Industrial Aluminum Alloy Electric Heating Towel Rack Bracket Aluminum Profile

High Precision Quality Customized Laser Marking Machine Aluminum Profile

High End Precision Quality Jewelry Showcases Aluminum Profiles Parts Cases Frame

OEM Custom Aluminum Alloy Die Casting LED Lighting Housing

High Precision Quality Cylindrical Sun Flower Aluminum Heat Sink Led Aluminum Profile

Aluminum Alloy Panel Customized Stamping Processing Customized Aluminum Alloy Keyboard Base