Polyester Yarn Manufacturing Process | From Chips to Cone Yarn

Polyester is currently an important fiber type among synthetic fibers, because of the fastest development speed and the highest output. The production of polyester filament can be roughly divided into two steps: spinning and post-processing.

Audited supplier

Audited supplier#1 Spinning

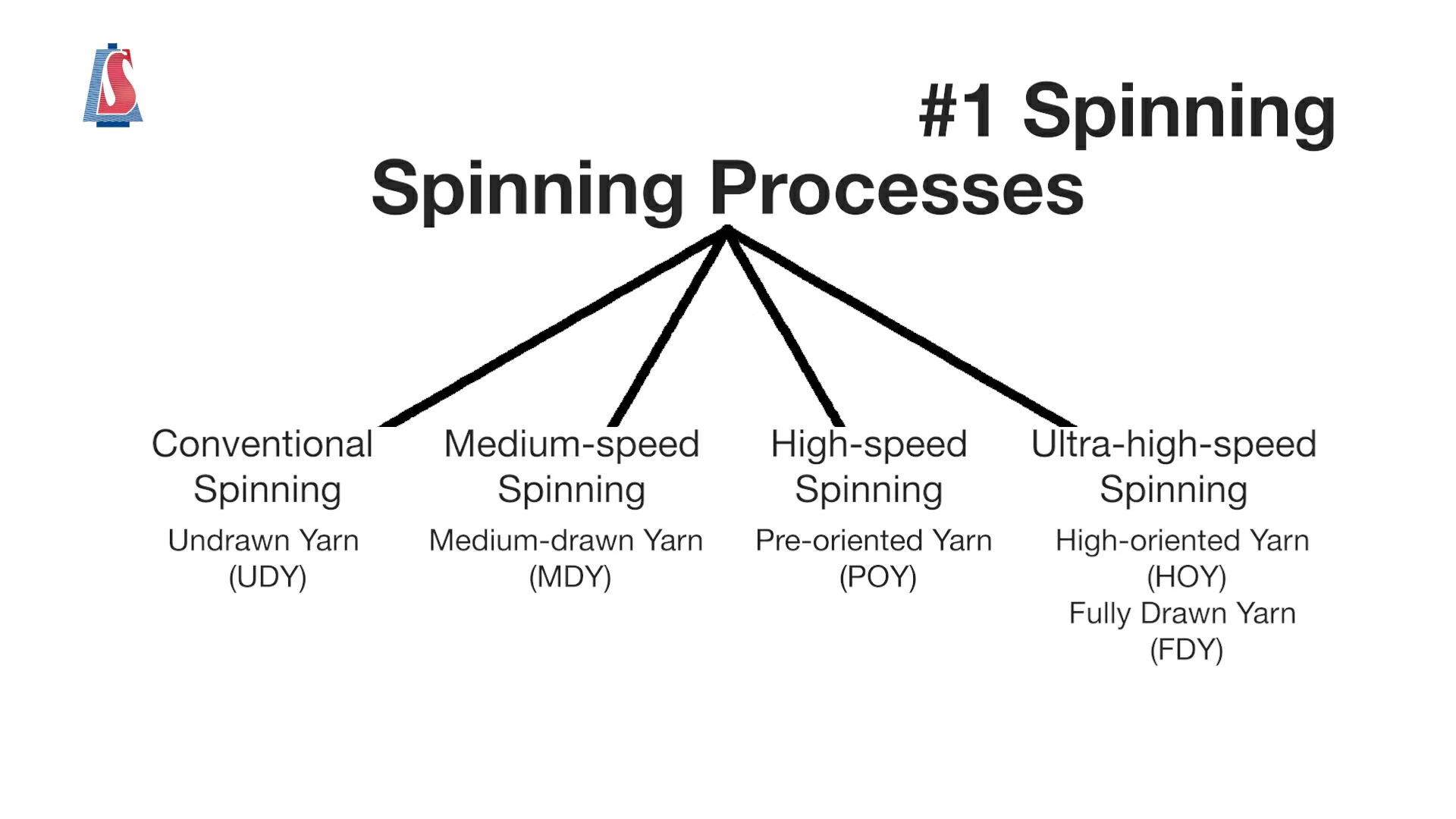

According to the spinning speed, the spinning process can be divided into the conventional spinning process, medium-speed spinning process, high-speed spinning process and ultra-high-speed spinning process.

Generally speaking, the product after the conventional spinning process is undrawn yarn (UDY), the product after the medium-speed spinning process is medium-drawn yarn (MDY), the product after the high-speed spinning process is pre-oriented yarn (POY), and the product after the ultra-high-speed spinning process is high-oriented yarn (HOY) or fully drawn yarn (FDY).

We will use high-speed spinning, the most commonly used process route for the production of textured yarns, to illustrate the spinning process.

The spinning speed of high-speed spinning is 3000-3600m/min, and the product after this process is pre-oriented yarn (POY).

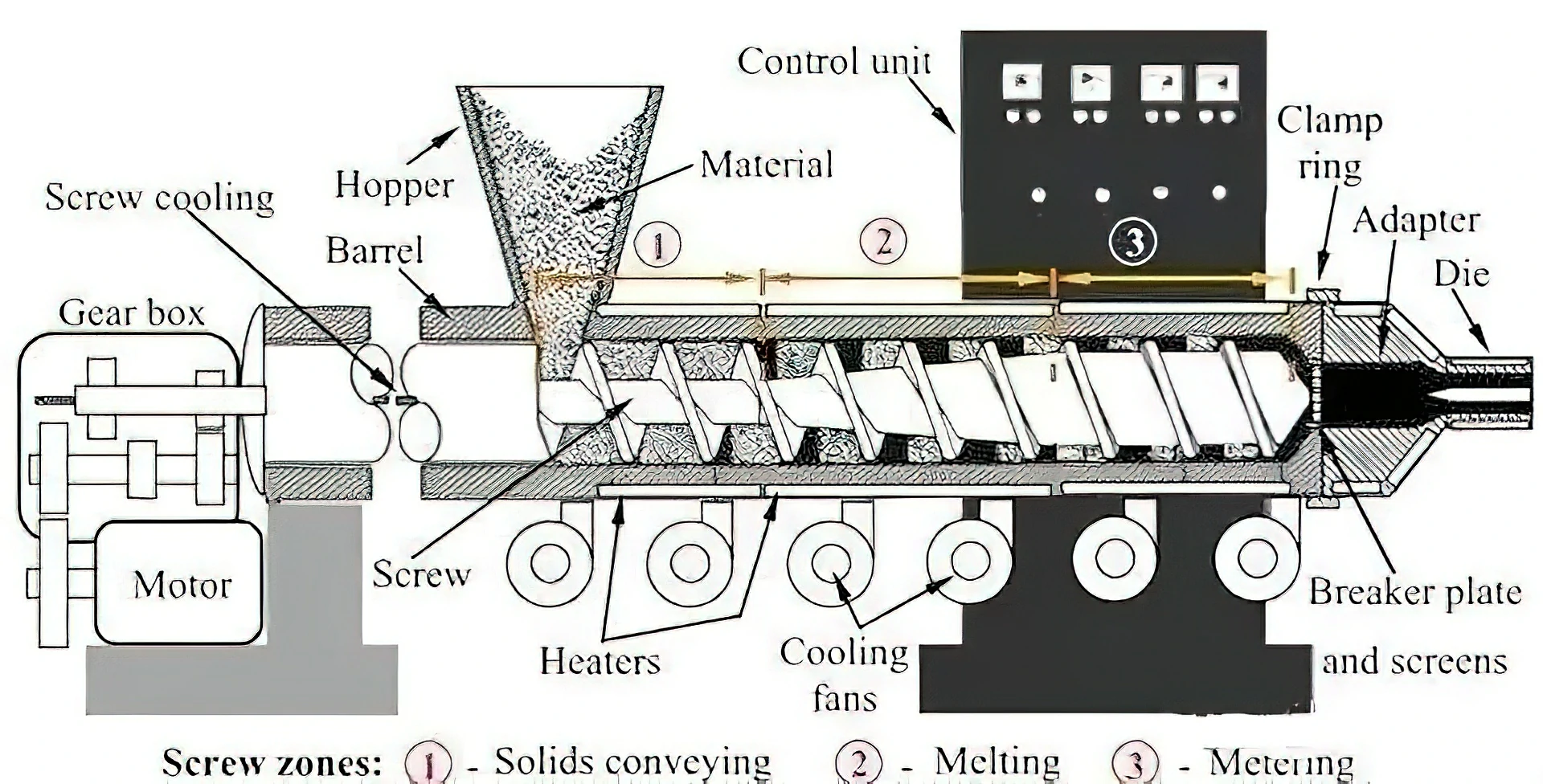

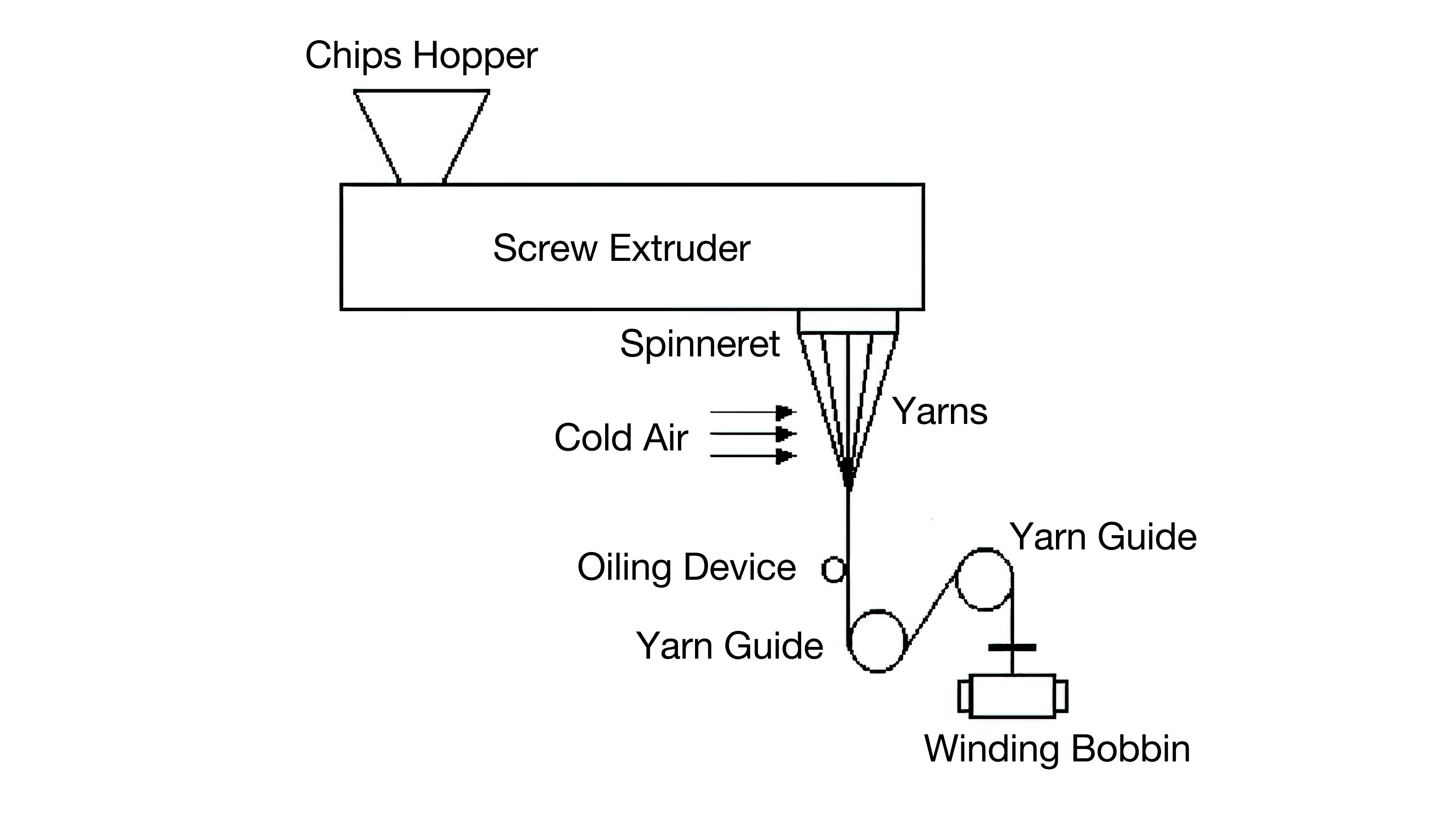

The principle of the process is to feed polyester chips into the chips hopper, then melt them, and ensure that the melt flows stably in the screw extruder.

In the screw extruder, the melt is filtered and pressed into the spinneret to spray out a thin stream of melt, and then quickly condensed by cold air to form a solidified tow fiber.

During this process, pre-stretching is also generated due to the function of the yarn guide, and it also makes the fiber thinner.

The nascent fiber is wound into a roll with a certain shape by the winding system.

#2 Post-processing

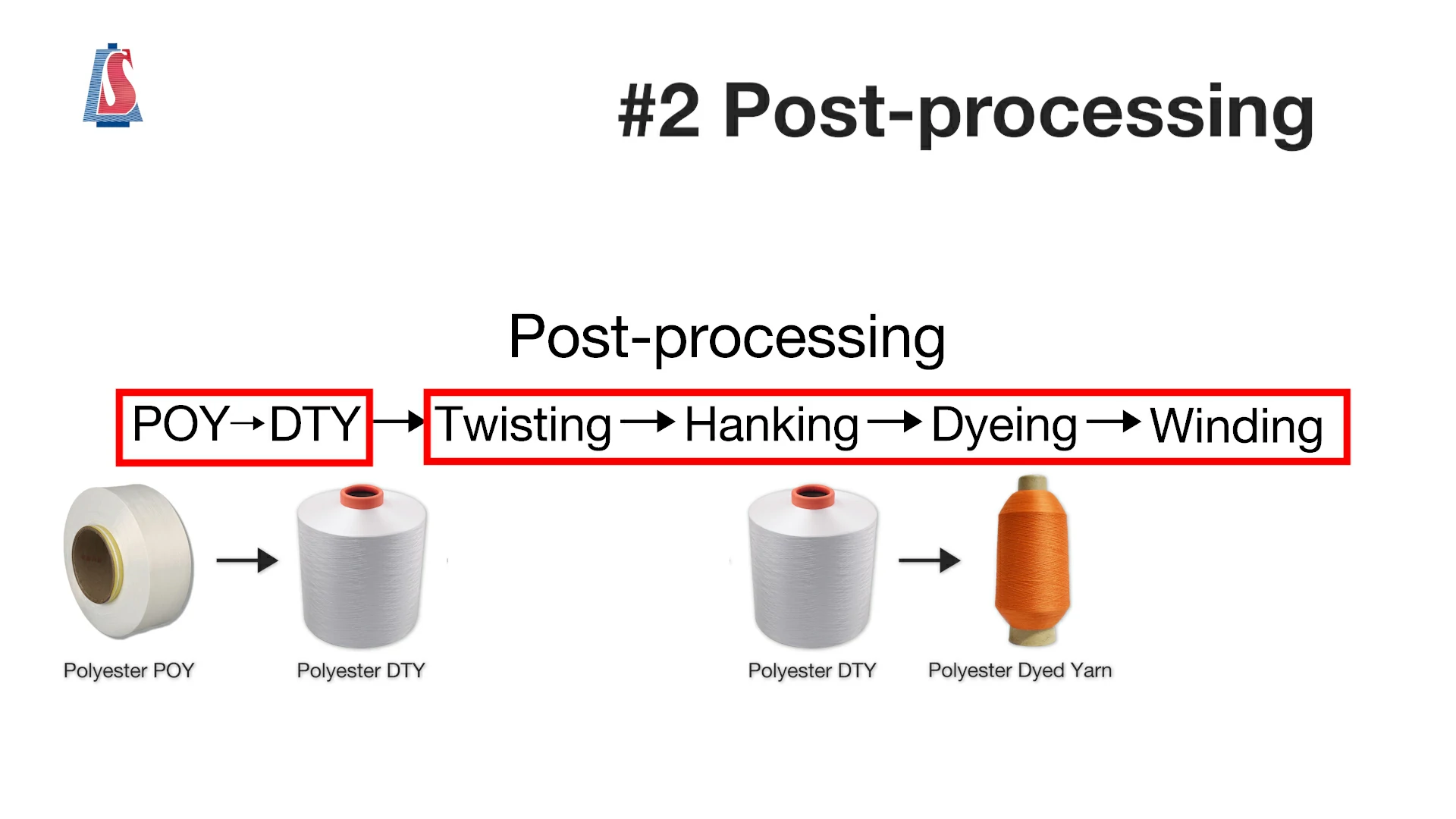

The post-processing of chemical fiber refers to the processing that can make the spun nascent fiber suitable for textile production. After a series of post-processing, the structure and properties of the fiber are improved.

Post-processing can be roughly divided into the following five steps: POY to DTY, twisting, hanking, dyeing, and winding. I will explain every step to you.

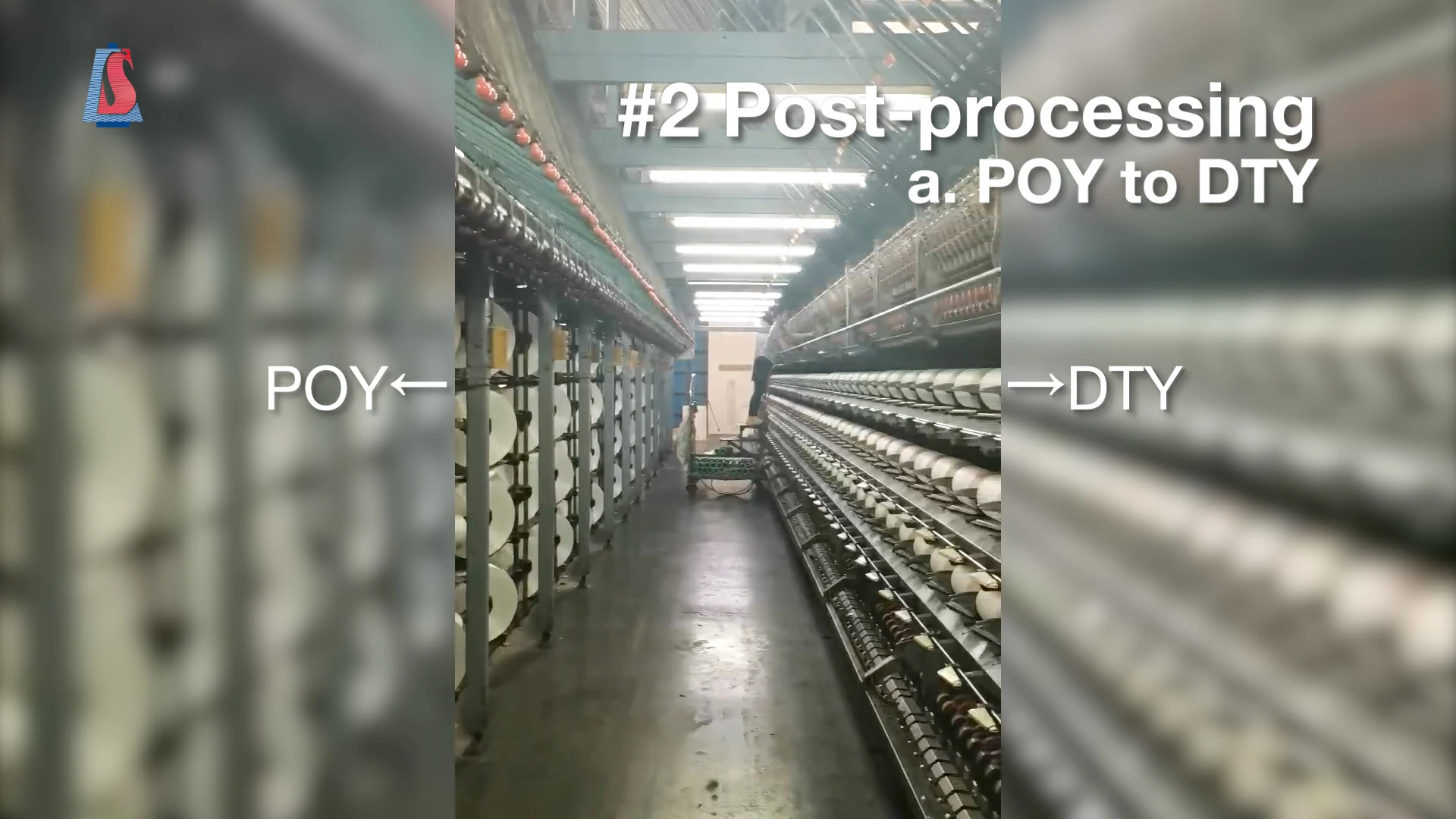

a. POY to DTY

Combining the drawing and twisting process on the same machine, the produced yarn is called draw texturing yarn - DTY.

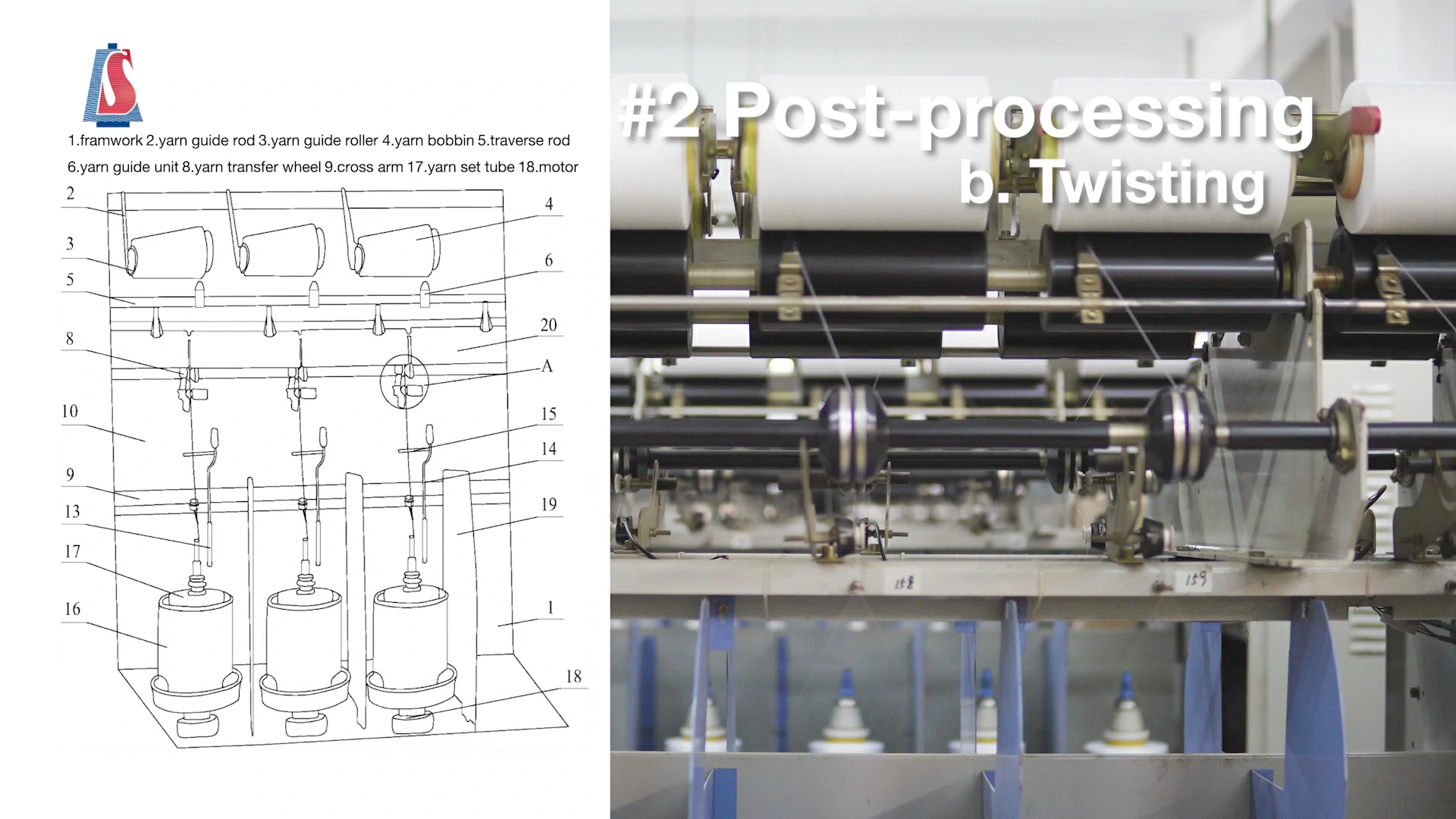

b. Twisting

Twisting refers to combining two or several single yarns together and twisting them through a machine to produce strong, elastic strands, with the properties of uniform thickness, smooth surface, and wear-resistance, to meet the needs of the subsequent process.

The workers will set the twist on the machine according to the customer's requirements, and wind one end of the DTY on the machine and the machine will operate the twisting process. When the required weight of twisted DTY is reached, it will stop and give a red light signal to remind workers.

c. Hanking

The purpose of hanking is to loosen the twisted yarn so that the dye can penetrate into the yarn completely during the dyeing process.

Workers will place the twisted product next to the machine, connect one end of the yarn to the machine, and turn on the machine.

During the process of hanking, workers will add some water appropriately to tighten the yarn a little bit.

After hanking, the product becomes "bread yarn". Then it will be packed, bagged, and then transported to our dyeing factory for dyeing.

d. Dyeing

Before the mass dyeing, professional color staff will prepare the color formula according to the customer's sample and dye it with a dyeing machine. Then, they compare the dyed sample with the customer's sample under the specified lighting environment. After confirming that there is no color difference, mass dyeing will be carried out.

Hank dyeing, dope dyeing, and cone dyeing are the three most commonly used dyeing methods.

The dyeing method used in our factory is hank dyeing. Compared with other dyeing methods, hank dyeing has the characteristics of high color fastness and uniform dyeing. Our dyeing factory is equipped with dyeing tanks of different specifications, and the yarn dyeing weight ranges from 1.5kg to 800kg. Small dyeing tanks are generally used to dye sample yarns for customers.

Dyeing is a link that tests experience and technology the most, because this process requires not only precise dye ratios, but also temperature control. At the same time, workers must add additives at appropriate times based on experience for the corresponding functions, such as waterproof, heat preservation, antibacterial, etc.

e. Winding

Winding is the last process of yarn post-processing. Its task is to process the hank yarn into the cone yarn, which is the product that our customer can directly use to produce the textile products, such as socks and medical bandages.

Before winding, workers will place the dyed "bread yarn" in a cool place and dry it with the wind. This process generally lasts 2 to 3 days.

Then the workers put the dried colored "bread yarn" on a shelf, spread it out evenly, and cut off the surface yarn that has been exposed to air for a long time.

When it's all done, workers will place it on the machine, and turn on the machine to wind it.

After winding, the cone yarn will be placed on a shelf, and after passing the inspection by the workers, it will be packed, stored and sent out to our customers.

Audited supplier

Audited supplier

Polyester Yarn Manufacturing Process | From Chips to Cone Yarn

Polyester Yarn vs Nylon Yarn | Yarn Properties

70D Nylon DTY Twisted

What is Dope Dyed Yarn? - Textile Encyclopedia - Salud Yarn

What is Semi-Dull Yarn? - Textile Encyclopedia - Salud Yarn

What is Sarry Yarn? - Textile Encyclopedia - Salud Yarn

What is Cotton Yarn? - Textile Encyclopedia - Salud Yarn

What is Tex of Yarn Count? - Textile Encyclopedia - Salud Yarn

What is Denier of Yarn Count? - Textile Encyclopedia - Salud Yarn