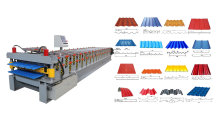

double layer roofing sheet roll forming machine

Sometimes when a client needs to produce two different metal sheets, cladding, trapezoidal, corrugated sheets or metal tiles, a double layer roll forming machine always comes to mind.Compared to a single layer roof panel roll forming machine, a double layer roll forming machine is desgined to produce two different kinds of metal sheets which can be one trapezoidal roofing and one roof/wall cladding sheet; or one trapezoidal roofing sheet and one corrugated roofing sheet; or one trapezoidal sheet and one metal roof tile; or one corrugated sheet and one metal glazed roof tile etc. To sum up, any two of the metal roof panels can be produced by this same double deck roll forming machine.

Sometimes when a client needs to produce two different metal sheets, cladding, trapezoidal, corrugated sheets or metal tiles, a double layer roll forming machine always comes to mind.Compared to a single layer roof panel roll forming machine, a double layer roll forming machine is desgined to produce two different kinds of metal sheets which can be one trapezoidal roofing and one roof/wall cladding sheet; or one trapezoidal roofing sheet and one corrugated roofing sheet; or one trapezoidal sheet and one metal roof tile; or one corrugated sheet and one metal glazed roof tile etc. To sum up, any two of the metal roof panels can be produced by this same double deck roll forming machine.

Brief introduction of double layer roll forming machine:

Double layer roll forming machine

A double layer roll forming machine has two layers or two levels of roll forming parts which gives it another name dual level roll forming machine, and because this machine makes two metal sheets, and double sheet roll forming machine is also a familiar name to people. (Similar machines are like two-in-one roll forming machine and cassette type roll forming machine.)It shall be pointed out that the two layers of roll forming parts on this double layer roll forming machine cannot work at the same time, which means each one of the roll forming systems (top roll forming and bottom roll forming) will stop when the other is working. The two layer or two levels roll forming parts share a same motor and the change of running between top and bottom roll forming part is made through a clutch equiped on this double deck roll forming machine.

Double sheet roll forming machine for IBR roof sheet and corrugated roof sheet

A double sheet roll forming machine usually consists of a decoiler, two entry feeding guides with entry shearing optional, two roll forming systems, one Cutting frame with two cutting dies (a hydraulic pressing will be equiped as long as this dual level roll forming machine is designed to produce metal glazed roof tiles ), one transmission system, one control system and runout tables. Hydraulic decoiler and auto stacking machine are optional to this double layer roll forming machine as per requirments. For European customers, there are safety cover as well as a CE sign on the machine body.

Technical Parameters for dual level roll forming machine:

• Uncoiler: Manual Uncoiler (a Hydraulic decoiler is optional);

• Inner diameter : 480-520mm;

• Outer diameter: 1250mm;

• Loading weight: 5TONS;

• Material width: 762-1250mm;

• Material thickness: 0.3-0.8mm;

• Forming speed: 0-12m/min (high speed is optional as per request);

• Forming steps: 16-22 forming stations (subject to the technical drawing of profiles);

• Material of Shafts:45# high-quality steel;

• Double layer roll forming machine for corrugated sheet and metal roof tile

• Diameter of Shafts: 70mm;

• Material of Roller: high quality 45#steel coated with hard chrome 0.05mm.

• Thickness of Siding Plate: 18mm;

• Transmission: by chain-brackets;

• Motor Power: 7.5 KW

• Material of cutting blade:Cr12 with quenched treatment 60-62 degrees;

• Material of pressing dies: Cr12 steel with queching treatment;

• Hydraulic Power: 4-5.5KW;

• Cutting Lengths and Quantities: this double deck roll forming machine will automatically cut the final sheets exactly as per required lengths and quantites clients set through the touch screen on PLC control box.

• Cutting tolerance: +/-2mm

• Control system: Panasonic PLC, Inverter, CHNT transformer and HMI

• Voltage: 380V/50HZ/3phase

Electric Tapping Machine

double layer roofing sheet roll forming machine

Step Beam Roll Forming Machine

0.12mm-6.0mm Thickness sheet galvanized steel coil

Color coated steel coil prepainted galvanized steel coil

Ridge capping roof machine

Steel Keel Forming Machine

Double-layer Roll forming machine

Wall Panel Tile Making Roll Forming Machine