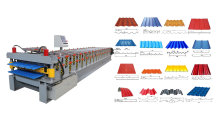

Wall Panel Tile Making Roll Forming Machine

The finished product of Profile Use Metal Steel Tile Roll Forming Machine is widely used in the construction of various industrial plants, villages, warehouses, supermarkets, hotels, exhibition, family construction, shopping malls shutter doors and etc. It has the advantage of beautiful, classical appearance and grace taste.

The finished product of Profile Use Metal Steel Tile Roll Forming Machine is widely used in the construction of various industrial plants, villages, warehouses, supermarkets, hotels, exhibition, family construction, shopping malls shutter doors and etc. It has the advantage of beautiful, classical appearance and grace taste.

Main Technical Specifications:

NO.1 Feeding Platform Manual Pre-cutting Device | |

Frame Structure | Steel Plate Welded |

Roller Flatting System | let the feeding fluently |

NO.2 Roll Forming M/C | |

Installation Dimension | 8500mm*1400mm*1500mm |

Machine Under Frame | 350H-beam |

Sidewall Plate Thickness | 16mm |

Roller Stations | 16Steps |

Shaft Diameter | 70mm |

Main Shaft Material | 45# steel with finish turning |

Roller Material | 45# Forging Steel with Chromium Plate |

Chromium Plate Thickness | 0.05mm |

Motor Power | 5.5kw |

Reducer Type | 8#Cycloidal Planetary Gear Speed Reducer |

Chain Wheel and Cycle Chai | 1 Inch |

Roll forming Speed | 15-20m/min(adjusted with frequency changer) |

NO.4 PLC Control Cabinet The target piece length is adjustable and digit of it can be adjusted | |

PLC Control System | Delta |

Frequency Converte | Delta |

Voltage | 3phase/380V/50Hz(For confirmation ) |

NO.5 Hydraulic Cutting System It adopts hydraulic drive and automatic location system to decide the dimension and cut the target . | |

Working Method | Stop to cut then post cut |

Hydraulic Tank | 1 set |

Hydraulic Pump Station | 3KW |

Cutting Length Tolerance | 10m ±1mm |

Cutting Tool Material | Cr12 with quenched treatment 58°C-62°C |

NO.6 Exit Rack | |

Function | Load Steel Purline |

Length/set | 3 meters |

Main Components:

Item | Name | Qty |

1 | 5T Manual Decoiler | 1 |

2 | Feeding platform with hand cutting system | 1 |

3 | Main forming system | 1 |

4 | Hydraulic cutting system | 1 |

5 | Hydraulic pump station | 1 |

6 | Electrical motor | 1 |

7 | PLC control system | 1 |

8 | Touch screen operation | 1 |

9 | Finished products receive table | 1 |

10 | Safety shield(optional) | 1 |

11 | Hydraulic decoiler(optional) | 1 |

12 | Automatic stacker(optional) | 1 |

Electric Tapping Machine

double layer roofing sheet roll forming machine

Step Beam Roll Forming Machine

0.12mm-6.0mm Thickness sheet galvanized steel coil

Color coated steel coil prepainted galvanized steel coil

Ridge capping roof machine

Steel Keel Forming Machine

Double-layer Roll forming machine

Wall Panel Tile Making Roll Forming Machine