The newest Cutting Robot on sales

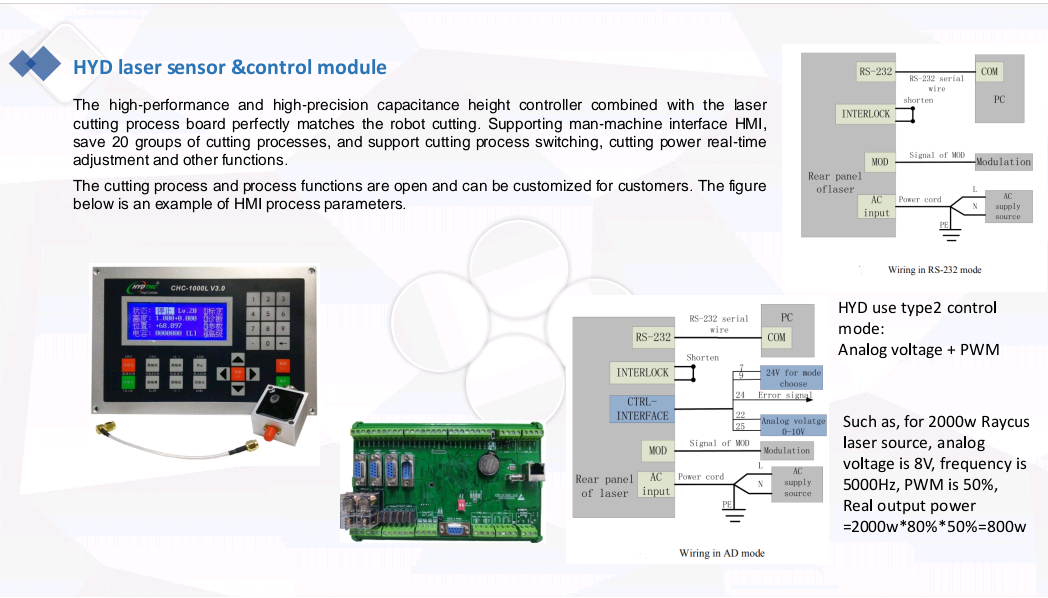

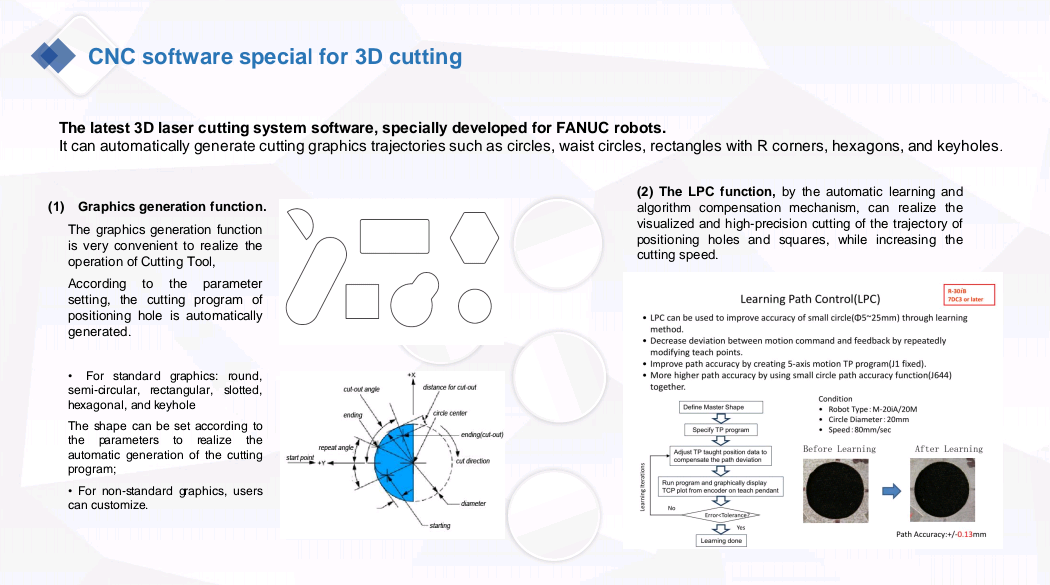

(1) We attach great importance to product stability. So we have focused on optimizing the circuit, air circuit and cooling system, and all core components are selected from international or industry-renowned brands. (2) Our equipment has strong scalability in the later stage. It can add dust and smoke protection room, rotating workbench, mobile workbench, automatic tooling and other applicable configurations according to customer requirements, and can realize sevenaxis and eight-axis linkage. (3) Our 3D special cutting head is equipped with anti-collision system as standard, and can quickly return to position after collision. (4) In response to the high-precision control requirements of laser cutting, we optimized the motion program of the manipulator and jointly developed the 3D laser cutting system software with FANUC. (5) We have developed a three-dimensional dedicated follow-up system, which can not only adjust the frequency, power, and duty cycle of the laser, but also has a hierarchical perforation process, which is very convenient to adjust the threedimensional cutting process. (6) Our 3D laser cutting head can be calibrated in real time and can prevent magnetic field interference. These two functions greatly improve the stability of the cutting head and greatly reduce the number of calibrations. (7) Offline programming mapping software can be selected for customers, which greatly shortens the calibration time and improves production efficiency. (8) Our equipment is easy to operate, and can be on duty within a week of normal training, and we provide lifelong free training services.

Audited supplier

Audited supplierrobot 3D laser cutting machine The robot 3D laser cutting machine is an efficient combination of a six-axis industrial robot and a fiber laser source. With a lightweight design of the 3D special anti-collision cutting head, it can realize the space curve trajectory cutting of 3D covers or special-shaped pipes, and can add multiple additional axis realizes seven-axis and eight-axis linkage.

1.About The Ventilation System Of Laser Cutting Machine

The principle of a metal laser cutting machine processing metal sheet is to irradiate the sheet metal surface with a high-energy laser, and the high temperature makes it quickly melt to achieve the purpose of cutting. In the process of metal laser cutting, high-temperature burning of metal will produce a small amount of exhaust gas. In order to ensure the safety of the operator, there will be certain requirements for the ventilation system. We recommend two ventilation methods as below.

2.What products can we offer?

We can offer fiber laser sources, fiber laser cutting machines, fiber laser welding machines, cutting and welding robots, etc.

3.How long is our machine's warranty?

Laser power: Two years warranty, Guaranteed by laser power manufacturer; Machine table: Two years warranty, Guaranteed by Lonwill; Electronics and motion parts: One year warranty, Guaranteed by parts manufacturer; Lifetime free software upgrade service; Customer service response time within 24 hours, please let us know at the first time if you have any question about any parts; Free Warranty Service: We will send replacement parts on our cost first, keep customer's machine running is a top concern;

Advantages

1.Working in the CNC cutting field since 2004, all the engineers have rich experience and problem shooting ability to offer a comprehensive service

2.The careful sales team patiently solves every problem about the machine and the best warranty services.

3.OEM fiber laser cutting machine manufacturer

4.Customized production to maximize your needs at the most reasonable price

About Lonwill

Shenzhen Lonwill Technology Co., Ltd. is specialized in CNC Cutting&Wedling automation solutions. With professional engineer team from HYD.CNC, we have started to supply CNC control system for plasma&oxyful cutting since 2004. We got into Laser cutting field in 2008 when YAG laser cutting machine was very hot on market. Almost all YAG laser cutting machine manufacturers like DNE laser, HSG laser...used our CHC-300 cap sensors for laser cutting height control. Just because of that, Our cap height sensor CHC-1000 series for fiber laser cutting got delayed. When our CHC-1000 came to market in 2015, Cypcut system has taken all fiber laser cutting market in China. Meanwhile YAG laser cutting was being replaced by fiber laser cutting fastly. We had to work with PA8000, Beckhoff such foreign controllers for pipe cutting, laser welding and Robotic cutting...etc. Meanwhile, we started to offer complete fiber laser cutting machine, and machine integration service like robotic laser cutting, customized laser welding......which opened a new world for us! More and more professional engineers joined our team in recent years, which enable us to make more and more automation solutions to clients around the world. With our R&D centre in Shenzhen and machine factory in Foshan, we can support you to make machine on your own, or supply complete machine according to your request.

Audited supplier

Audited supplier

Why most user choose 30kW not 20kW or other power lasers?

3D robotic laser welding case -double station & cutting

12000W EtherCat protocol controller Fiber Laser cutting Machiine

Quality Ultra-fast fiber laser tube cutting machine for small pipes Manufacturer | Lonwill

A New Process for Cutting Small Rectangular Workpieces

12000W EtherCat protocol controller Fiber Laser cutting Machiine

Professional High-power, fully enclosed, switching table laser cutting machine OEM manufacturers

Professional Tube cutting machine be installed in mass manufacturers

Newest technology 6kW Fiber laser cutting hole _Countersinking process