Why most user choose 30kW not 20kW or other power lasers?

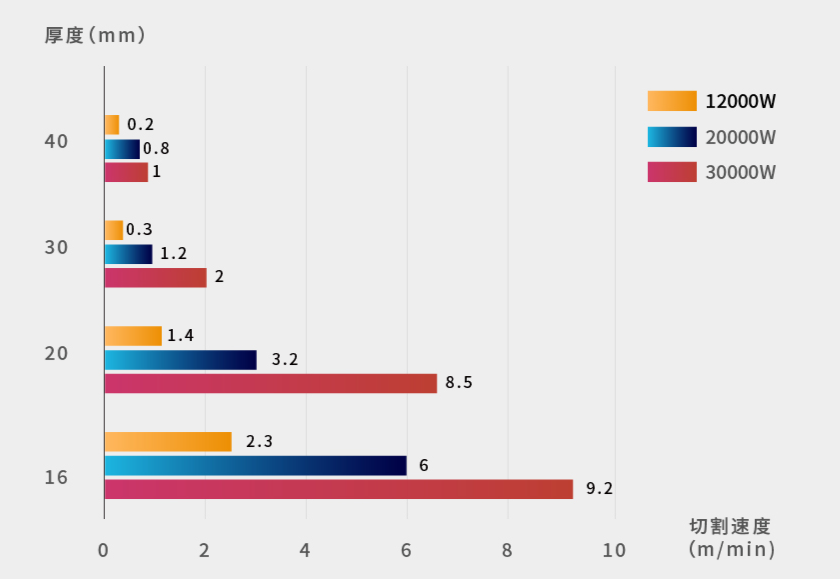

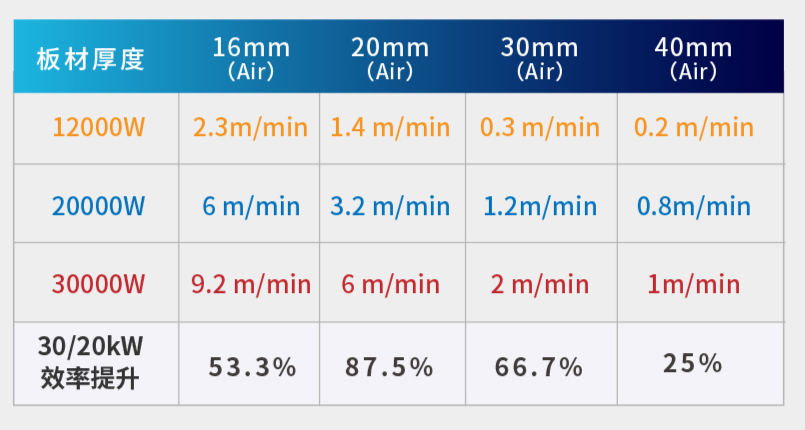

Taking the air cutting of stainless steel below 30mm as an example, the cutting speed of Raycus 30kW is doubled on average compared with the previous 20kW, and the cutting efficiency is increased by more than 50%. The cutting speed of 20mm carbon steel is higher than that of multi-mode 20kW cutting efficiency. more than 80%.

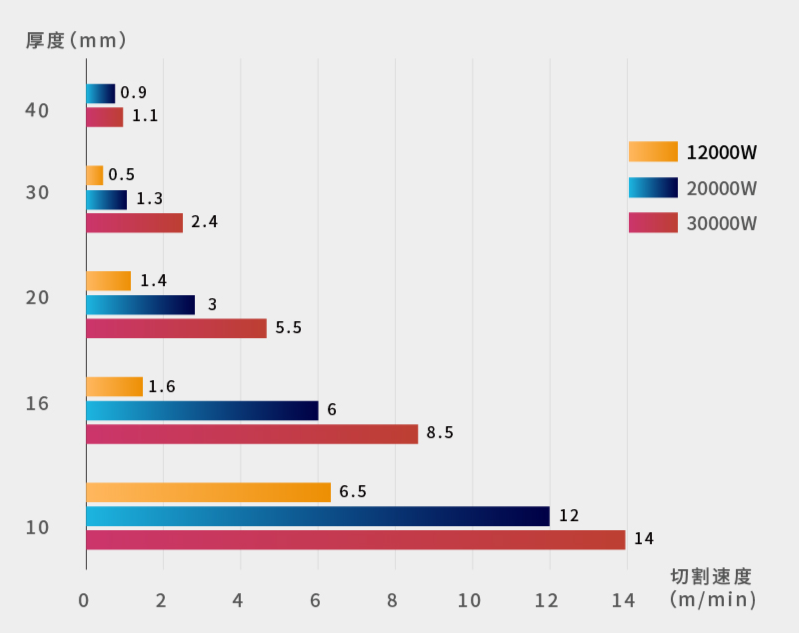

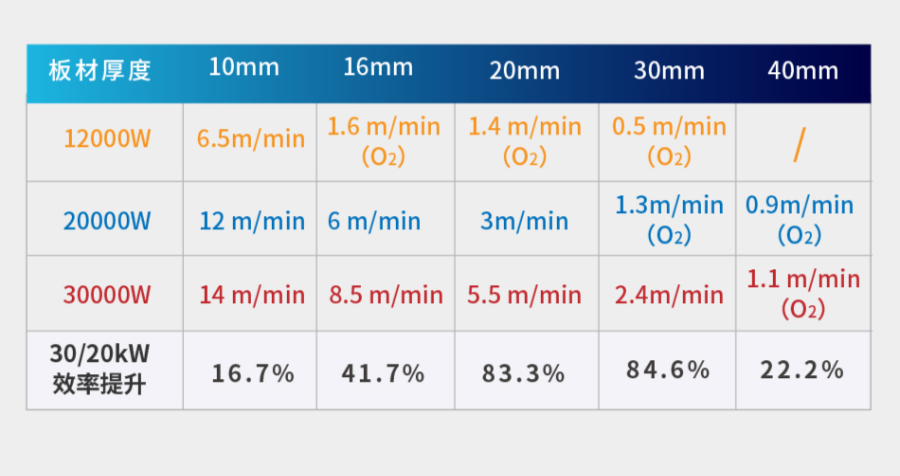

30kW laser iron plate oxygen cutting can reach 50mm bright surface cutting, air cutting can reach 35mm. The oxygen conventional cutting and air cutting speed below 40mm are significantly improved, and the plate thickness is increased.

Undoubtedly, under the same conditions, the higher the laser power, the faster the processing speed, and the more significant the improvement in production efficiency. This means that for our company, the speed of making money is faster. Of course, the higher the power, the better.

Audited supplier

Audited supplierFrom these graphs you can see the advantage of 30KW at a glance, all parameters take Raycus laser as an example

Multi-module 30kW vs 20kW vs 12kW stainless steel cutting comparison

Multi-module 30kW vs 20kW vs 12kW carbon steel cutting comparison

Audited supplier

Audited supplier

Why most user choose 30kW not 20kW or other power lasers?

3D robotic laser welding case -double station & cutting

12000W EtherCat protocol controller Fiber Laser cutting Machiine

Quality Ultra-fast fiber laser tube cutting machine for small pipes Manufacturer | Lonwill

A New Process for Cutting Small Rectangular Workpieces

12000W EtherCat protocol controller Fiber Laser cutting Machiine

Professional High-power, fully enclosed, switching table laser cutting machine OEM manufacturers

Professional Tube cutting machine be installed in mass manufacturers

Newest technology 6kW Fiber laser cutting hole _Countersinking process