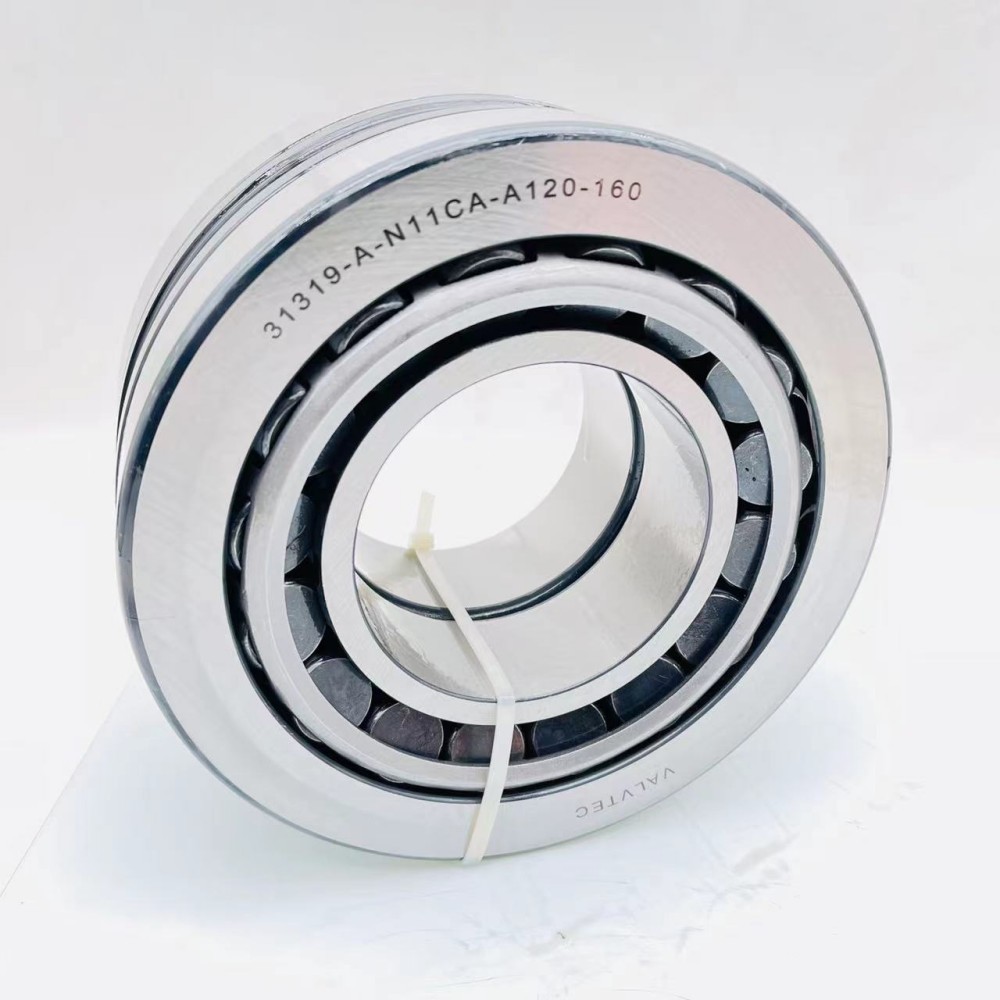

Vibration bearings

Zhejiang waxing electromechanical co.LTD.2023-11-090 views

Vibration bearings are bearings specifically designed to reduce machine vibration and noise. It is different from ordinary bearings, which are usually equipped with many elastic elements, such as springs. When rotating, these elastic elements absorb vibrations and noise and prevent them from being transmitted to other parts of the machine. Therefore, vibration bearings are often used in machines with high-speed rotation and high-frequency vibration, such as aerospace engines and wind turbines.

The main differences between vibration bearings and ordinary bearings are reflected in the following aspects:

Structure and design: The structure and design of the vibration bearing are optimized for the vibration environment to cope with harsh working conditions such as vibration and shock. In contrast, ordinary bearings follow general engineering design points and pay more attention to the internal structure and specifications of the bearing.

Material selection: Vibration bearings usually use particularly hard and wear-resistant materials, such as carbide, ceramics or special steels. These materials help bearings function properly under harsh conditions such as high pressure, high temperature and friction. Ordinary bearings generally use ordinary metal materials and have relatively low requirements on material quality and manufacturing process.

Performance requirements: Since vibration bearings need to cope with harsher working environments, they have higher wear resistance and load-bearing capacity, as well as higher processing accuracy to ensure stability and long life. Ordinary bearings have relatively low performance requirements and are generally suitable for applications with smaller loads, lower speeds and less wear.

You may also like

Best Quality Square Interlocking RC123006 Slide Retainer High Precision Injection Mold Parts Factory

Folding Shelf Brackets

Customized Non-standard mold parts For plastic injection Mold manufacturers From China | BAITO

Customized Toothed-Plate Connector Manufacturers From China

Customized Non-standard mold parts For plastic injection Mold manufacturers From China | BAITO

Customized Bike Rack manufacturers From China

Metal Web Joists

Quality Non-standard mold parts For plastic injection Mold Manufacturer | BAITO

Best Non-standard mold parts For plastic injection Mold Company - BAITO

Customized Non-standard mold parts For plastic injection Mold manufacturers From China | BAITO