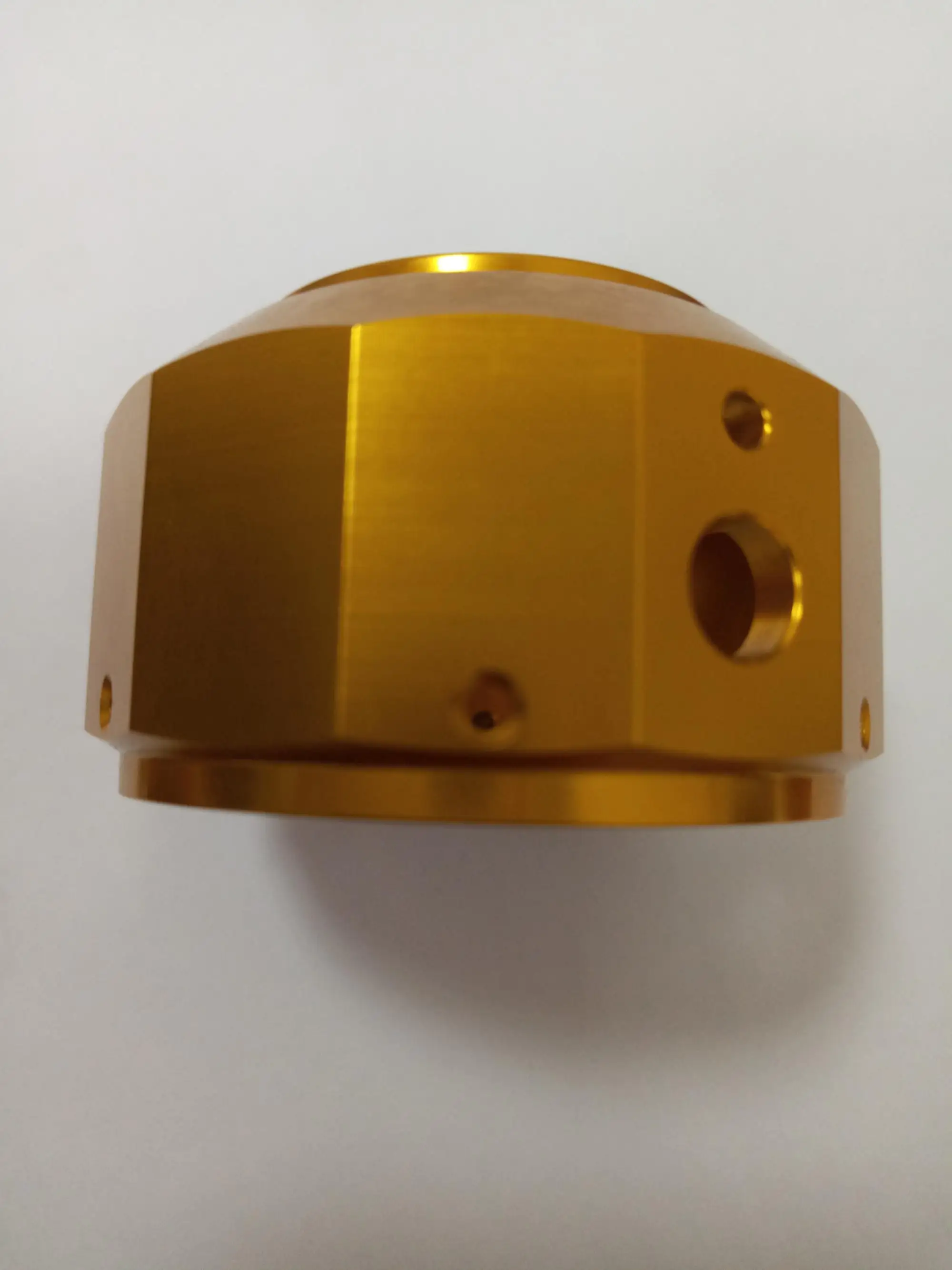

High Precision Custom Made CNC Machining/Machined Aluminum/Steel/Copper/Brass Parts OEM & ODM Service Factory Price

Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine,

transportation equipment, Valve and Pump system, Agriculture machine

metal Parts, engine bracket, truck chassis bracket, gear box , gear housing ,

gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe,

hydraulic valve, valve housing ,Fitting , flange, wheel, fly wheel,

oil pump housing, starter housing, coolant pump housing, transmission

shaft , transmission gear, sprocket, chains etc.

Metal custom CNC turned machining micro brass turning parts

Our CNC milling devices enable precision production of prototypes from aluminum, aluminum alloys, brass, zinc, tin and many more non-ferrous metals.

Product Description:

Item Name | Custom round CNC brass Turning Parts products made in asia |

General Products Application/Service Area |

Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system, Agriculture machine metal Parts, engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve, valve housing ,Fitting , flange, wheel, fly wheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc.

|

Main blank Process for Aluminum Casting | Die Casting, Permanent Molding /Gravity Casting, Low Pressure Casting, High Pressure Casting/Sand Casting, Extrusion Casting etc. |

Blanks Tolerance -Casting Tolerance |

CT4-6 for Permanent Molding, Die Casting, CT 9-11 for Sand Casting |

Applicable Material |

Nylon,ABS,PP,POM,PC.PE,TPU/TPR,PVC,PPS,HDPE Etc

|

Casting Blank Size /Dimensions | 2 mm-1500mm / 0.08inch-60inch , or according to customer requirements |

Casting Blank Weight | Range from 0.01kg-50kg |

Applicable Machining Process |

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming /Grinding/Honing and etc.

|

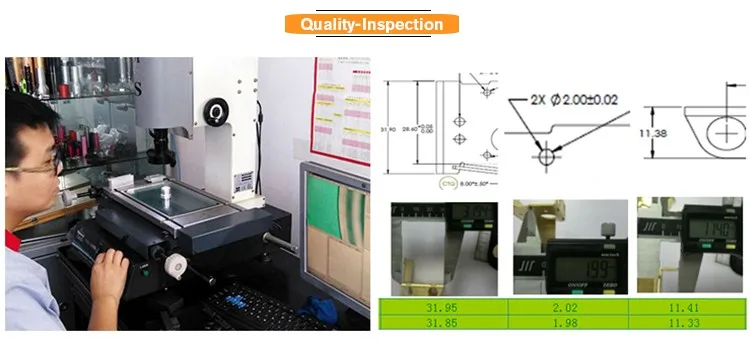

Machining Tolerance | From 0.005mm-0.01mm-0.1mm |

Machined Surface Quality | Ra 0.8-Ra3.2 according to customer requirement |

Applicable Heat Treatment | T5~T6 |

Applicable Finish Surface Treatment | Shot/sand blast, polishing, Primer Painting , Powder coating, ED- Coating, Finish Painting, Anodize (White or Black Color) |

MOQ | For die casting: 2000pcs For machining parts : 50pcs |

Lead Time | 45days from the receipt date of deposit for cnc milling aluminium |

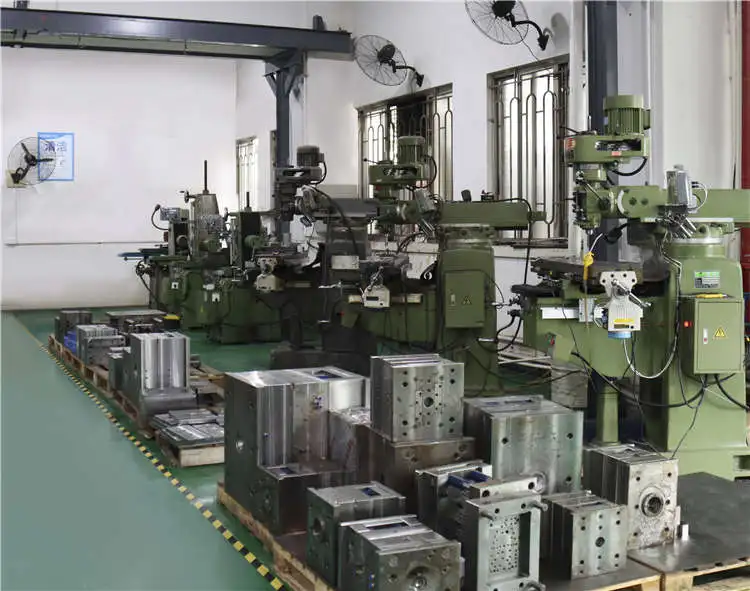

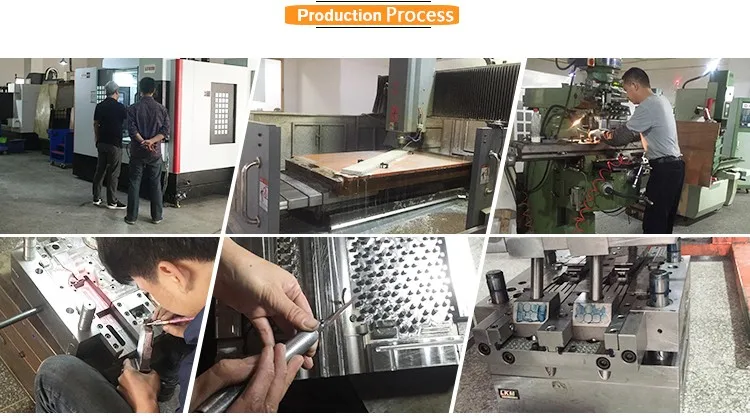

We are manufacturer and supplier of Plastic Injection Moulds and moulded components. The molds we manufacture is with high quality mold steels and high quality reputed standard parts. We do the design manufacture of molds and production of the moulded components in-house. Using latest softwares and high accuracy machines with highly experienced tool engineers

Our factory manufacturing for Prototype ,rapid prototype, rapid prototyping, CNC aluminium, plastic prototype, cnc prototype, prototype makers, cnc rapid prototype, metal prototype, prototype service, cnc machining prototype, cnc aluminum prototype, cheap rapid prototyping, rapid prototyping service.

3D PROTOTYPING

Building die cast or investment cast shapes from metal normally takes weeks of production. However, modern metal prototyping technology offers a much faster and more cost-effective solution in the form of rapid prototypes. Indeed, a rapid prototyping machine can produce even the most complex metal shapes in as short a period as a single afternoon.

What Is Rapid Prototyping? 3D PROTOTYPING

The 3D rapid prototyping process combines 3D CAD models and specialized printing machines that cut and additively sinter metal. Applications for rapid prototypes include prototypes, machine parts and production tools.

The specialized printers used for metal prototyping utilize an additive manufacturing technology known as direct metal laser sintering or DMLS. This process allows for highly complex geometries including curved or spiraled shapes with cavities and undercuts. The types of metals that can be used in 3D prototyping include aluminum, stainless steel and titanium.

As the name "rapid prototypes" suggests, turnaround times are often much faster than using traditional methods for producing metal shapes. A finished part can be created within just a few hours depending upon the size of the desired 3D prototype.

Our Service:

Depend on our experience from different side help customer Complete product idea design,

Provide Technological idea to save product development time,cost and reduce risk.

Provide design of Lay-out that is the position of the procession

Schedule about design,Manufacturing.

Working & Producing progression

provide free technical guidance or other help if customers need.

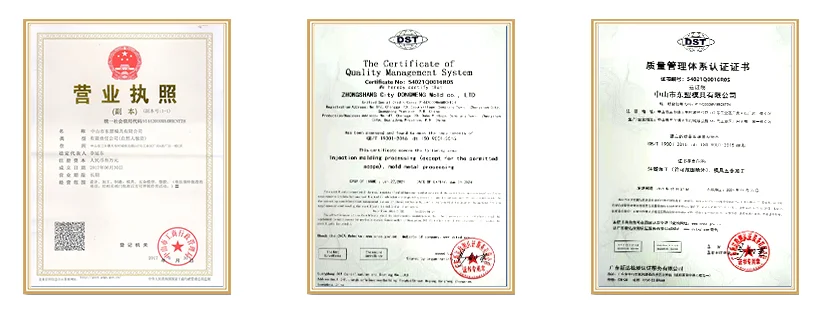

A. With 20 years specializing in producing prototype and mold.

B. Strong Enterprise innovation, with groups of professional engineers and salesmen

C. Engineers team more than 20 years experience in mold industry,Good at design and make.

D. Our high quality but low prices have gained market and public praise from domestic market.

E. We have no MOQ for clients and tailor-made to clients’ request.

F. We can offer OEM service

Best Supplier Metalworking CNC Lathe Milling Rapid Prototype Company - DOMOEG

Professional Supplier Metalworking CNC Lathe Milling Rapid Prototype manufacturers

Best Custom Metal Machining Precision Aluminum Parts CNC Machining Mechanical Parts Factory Price - DOMOEG

Customized Sell all kinds of complex metal prototype custom CNC machining manufacturers From China

Wholesale New arrival product cnc brass knuckle/brass part with good price - DOMOEG

China Metal custom CNC turned machining micro brass turning parts manufacturers - DOMOEG

Best sand casting aluminum at home / rubber molding hydraulic press vulcanization Supplier

Professional Custom Precision CNC Rapid Prototyping Accessories manufacturers

Professional Custom Metal Milling Turning Service Aluminum CNC Machining Parts with Laser Cutting diy New OEM