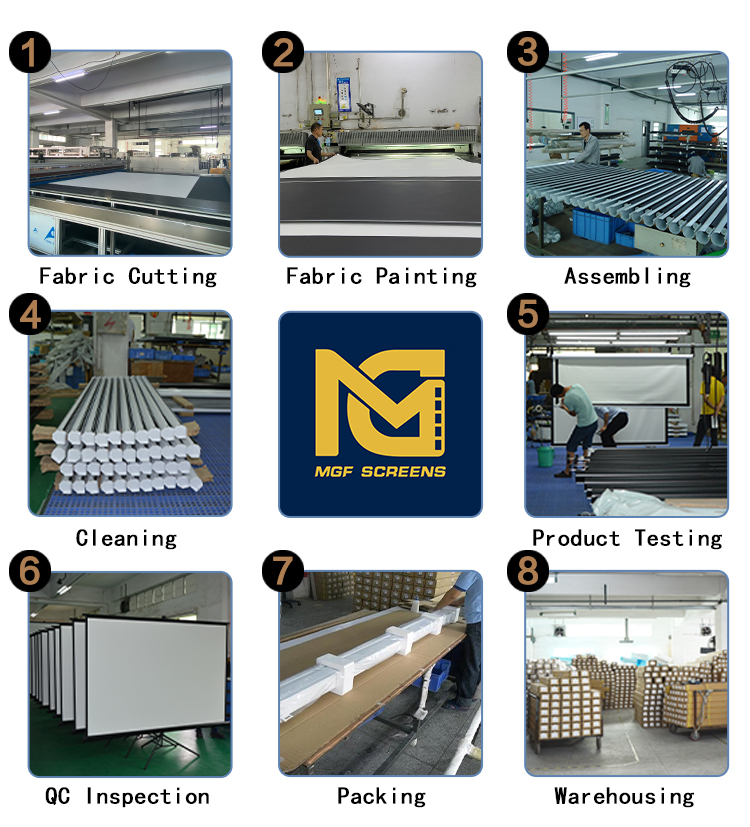

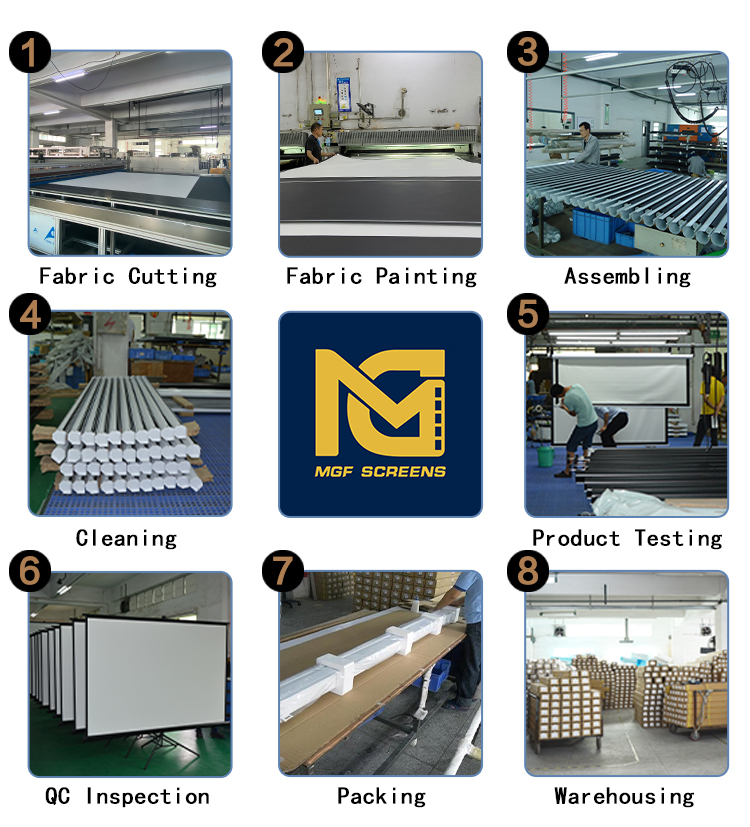

Hi Guys , today we will show you how our QC check the product quality.

The first step is to check the functionality of the product .

This is mainly reflected in whether the screen can be up and down by remote control set.

It includes RF remote control , IR remote control and manual switch .

Connect the manual switch to the screen , to check if "up" "down""stop" button can control the screen .

At the same time, test the infrared receiver function .

The second step is to check the visual area and the flatness of screen.

Measure and check the width and height of projection area .

Measure the upper black bottom , left and right black border .

Check the flatness of the fabric surface from the side, to see if there is edge curl.

The design of MGF SCREENS is a combination of various elements. They are lines, proportion, color, and fabric texture, garment construction, strong aesthetic sense, etc.

FAQ

1.What is the packagage?

We provide PE bag, shrinkage film,double cartons packaging,your own designed package is also available.

2.What payment method do you accept?

T/T (Bank transfer),L/C,Alipay, etc.

3.Do you offer guarantee for the products & How long do you offer for after-sales services?

12 months for all types of projection screen , except man-made damege.we are supplying free spare part for customer repair if quality issue.We do provide life time maintenance, but you bear all cost.

Advantages

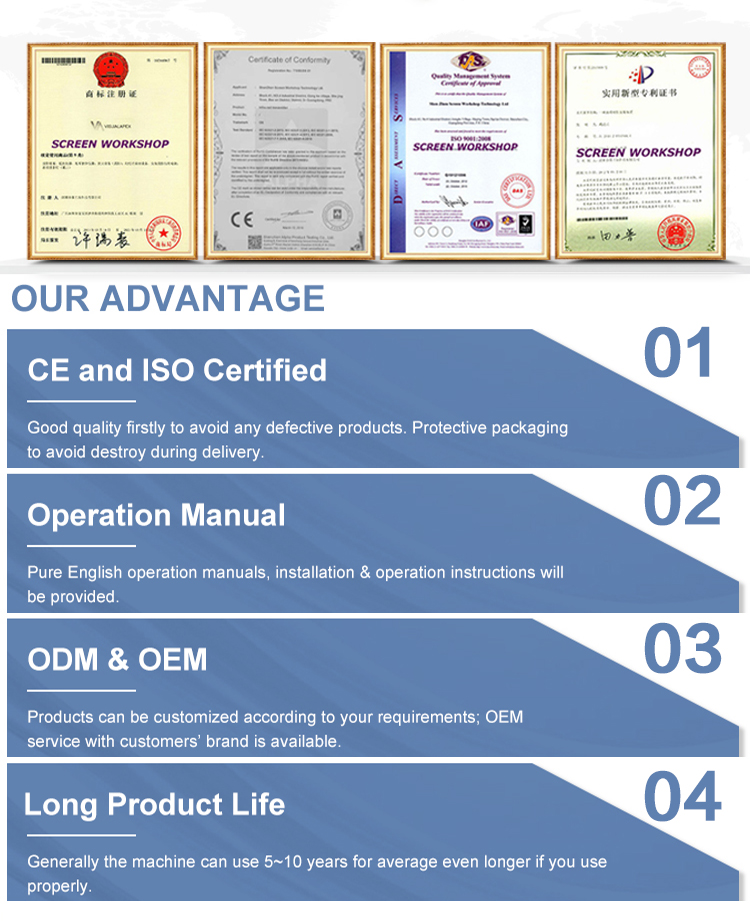

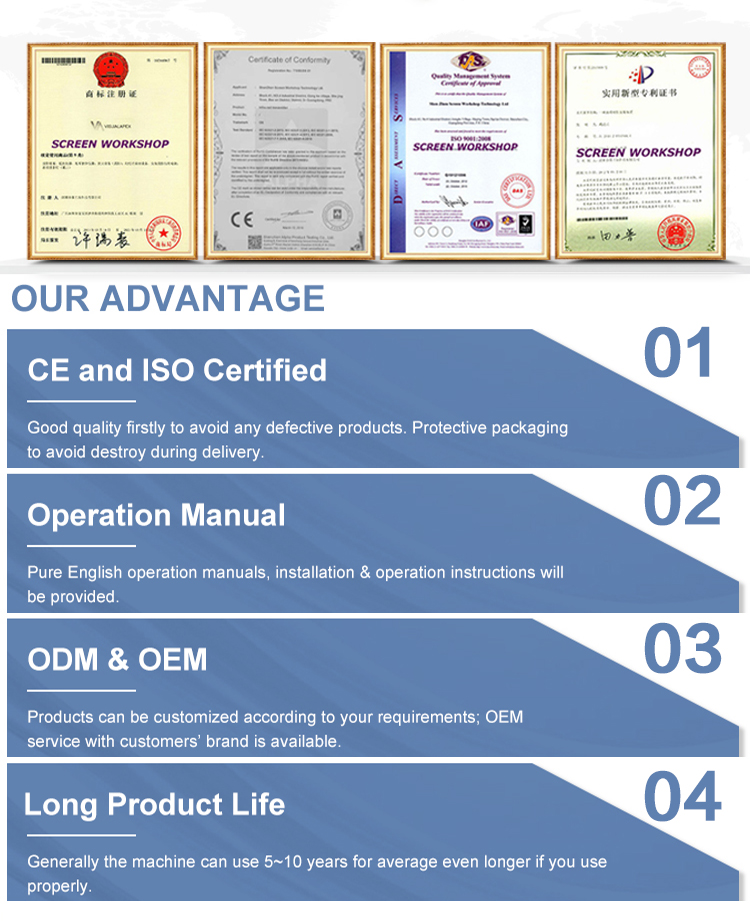

1.Established in 1999, Shenzhen Screen Workshop Technology Ltd. has more than 20 years experience in research, development, production, sales, and service for Projection Screens and Projection Mounts. We are specialized in the production of Projector Screens which can be used for home entertainment, education, business and so on. OEM and ODM are also applicable to us.

2.Customers Orientation: Best quality comes firstly. Generally the machine can used 5-10years for average even longer if you usd property.

3.CE and ISO Certified: Good quality firstly to avoid and defective products.Protective packaging to avoid destroy during delivery.

4.Operation Manual: Pure English operation manuals,installation&operation instruction will be provided.

About MGF SCREENS

Established in 1999,Shenzhen Screen Workshop Technology Ltd is a professional manufacturer engaged in the research, development, production, sale and service of Projection Screens and Projection Mounts. Located in Shenzhen,China with enjoying convenient transportation and beautiful environment and our company occupies an area of 8,000 square meters .We sincerely welcome friends from all over the world to visit our company and cooperate with us on the basis of long-term mutual benefits.

In recent years, our company has introduced a series of advanced facilities including of Automatic Packing Machine,Automatic bed cutting Machine and Automatic spraying equipment. Our annual production capacity is 200,000 pieces With export license.We are famous for superior quality,competitive prices,first-class craft works, safe package, and prompt delivery. Strict quality control is performed in every procedure from material sourcing, processing and testing to packing.Our products gain wide praises at home and abroad,we export products to Europe,America,Middle East and Southeast Asia.Our company has won ETL,CE,RoHS and other certifications.Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction.We will supply much better products with diversified designs and professional services.We also welcome OEM and ODM orders.

The third step is to check the cleanness of the screen

Check if the fabric surface is clean, use cleaning tools to remove dust .

Check if the housing has distortion and scratches .

And don’t worry if the housing is dirty, because the workers will do the final cleaning before packing .

When the check is over, unplug the power cord .

Audited supplier

Audited supplier

Audited supplier

Audited supplier