Assembly part by TIG welding process Products | MaiJin Metal

2 years ago

254

Share

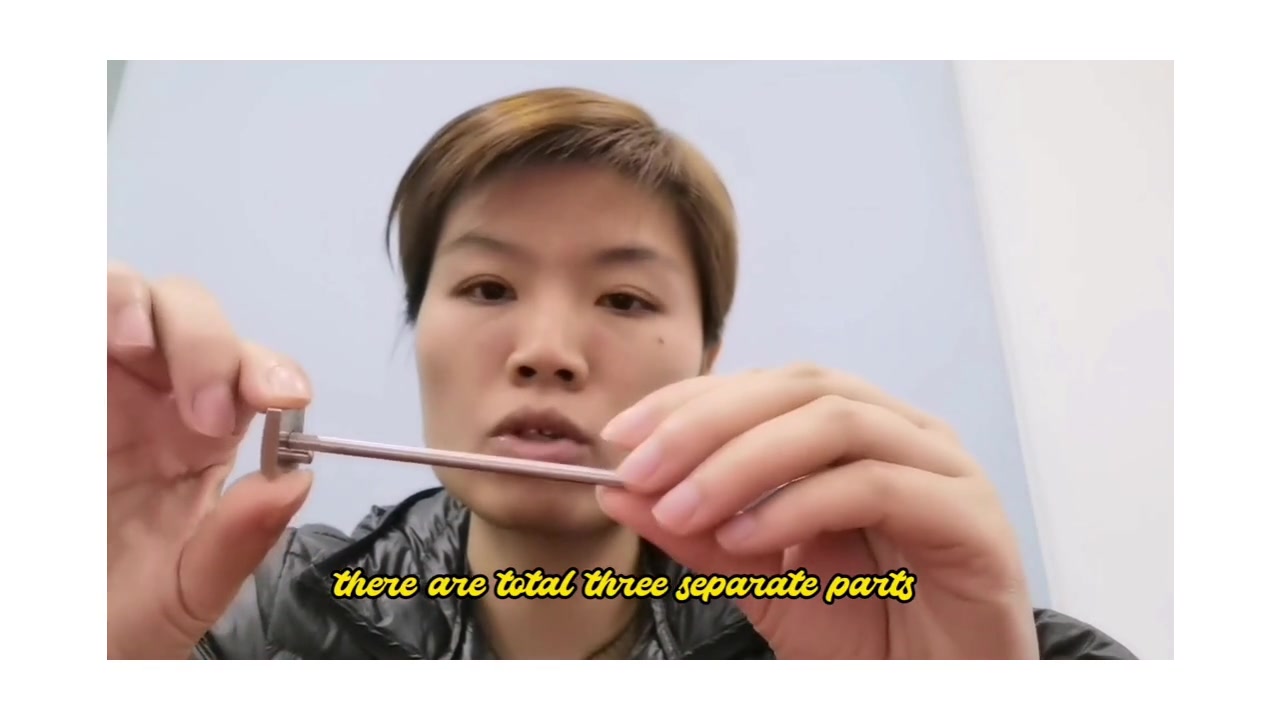

A fresh new sample, this is an assembly part by TIG welding process, there are total 3 seperate parts, the one is the extended square axis, the other is blocking edge, the last one is the cylindrical pin, after the welding process, we will do polish for the whole surface, the raw material for the 3 parts are all in SUS 316 with passivation, so the whole production cost will be reduced down a lot by the current production process.

视频 2022-03-03 11:19:48.

is designed with flexibility of use, durability and timeless desirability in mind.

Comments

No comments received

Suppliers

ShenZhen MaiJin Metal Works Co., Ltd.

Audited supplier

Audited supplier4YRS

Office Add: 10F, 9 Building Block B, Bao Neng Science and Technology Park, NO.1 Qing Xiang Rd, Long Hua District, Shen Zhen City, China.Factory Add: No.5 East Gate Wei Hua Industrial Park, Xiang Hao Rd, Tie Song village, Qing Xi Town, Dong Guan City, Chin

Product details

Comments

MaiJin Metal is innovatively developed. The development is conducted by our R&D team who try to find special metal coatings that can prevent fingerprints and other residues.

FAQ

1.Do you offer First Artical Inspection (FAI) reporting and Production part Approval Process (PPAPS)?

Yes, we offer FAI and PPAP reports for parts we make. Please let us know your specific QA reporting needs with your RFQ, and we will incorporate it into your quote. Additional charges may apply.

2.Are you ISO certified?

Yes! We are ISO9001:2015 certified.

3.What does "CNC" mean, exactly?

CNC stands for “computer numerical controlled” and refers to an automated manufacturing process in which pre-programmed software controls the movement of the machinery. CNC provides the consistent accuracy that makes it possible to produce precision parts.

Advantages

1.OEM/ODM services

2.Operating since 2006

3.Courage to challenge Many factories don’t want to produce some difficult material like SUS 316, Titanium, pure iron, alloy steel, but we got very interested in that and have finished lots of these parts. At the same time, we are also very glad to accept those difficulty and high precision parts, every challenge will take us to obtain more abundant processing experiences.

4.Strong engineering and technical team is committed to the improvement of technology and research and development which has been awarded a number of patents. R&D assists in the realization of difficult products and optimization of clamping devices to improve the production efficiency of mass products, greatly reducing the manufacturing cost and enabling customers to obtain more advantageous product prices.

About MaiJin Metal

Our products are sourced by BMW, Ford and Bosch

OEM/ODM services | 24-hour response time | ISO 9001:2015-certified

Operating since 2006

ShenZhen MaiJin Metal Works Co., Ltd. was founded in 2006. We have built up a good reputation for quality, service and reliability. With highly trained our sales people, experienced technical sales engineers and customer focus management systems, we have achieved the stable sales record at the forefront of our industry in providing high quality products and services to our customers.

Wide Range of Products to Choose from

Our core products range include: CNC machining parts, CNC milling parts, CNC turning parts, turned parts, non standard fasteners, thread stud,socket screw, jack screw, Standoffs, Precision Screw, Machine Parts, and Inserts for plastics, Shafts, Pin, Screws, Nuts, Spacers etc.

Mainly applied industry: 1. aerospace 2. shipping industry 3. automotive 4. electrical 5. telecommunication 6. Oil & Gas 7. Medical and Dental 8. Hydraulics

Company Introduction

Established in the year 2007 as a sole proprietorship firm, we ShenZhen MaiJin Metal Works Co., Ltd. are engaged in manufacturing & supplying a comprehensive collection of cnc machining parts, cnc milling parts, turned parts, fasteners. All these are available in varied models and specifications to meet the exact application demands at clients end. We make use of high grade material of construction in the production process so as to assure that the final range is in compliance with the industry standards. All the products are subjected to stringent quality testing on sample basis on well defined parameters before these are being delivered to the clients end.

Suppliers

ShenZhen MaiJin Metal Works Co., Ltd.

Audited supplier

Audited supplier4YRS

Office Add: 10F, 9 Building Block B, Bao Neng Science and Technology Park, NO.1 Qing Xiang Rd, Long Hua District, Shen Zhen City, China.Factory Add: No.5 East Gate Wei Hua Industrial Park, Xiang Hao Rd, Tie Song village, Qing Xi Town, Dong Guan City, Chin

You may also like

Best STREET LAMP ALUMINUM PARTS Factory Price - MaiJin Metal

Best ADAPTER OIL DRAIN 3/8 NPT Company - MaiJin Metal

Best QC COVER NUTS Company - MaiJin Metal

Customized SILICON BRONZE NUT manufacturers From China | MaiJin Metal

Quality Phillips fillister head machine screw Manufacturer | MaiJin Metal

Customized BOLZEN BOLT manufacturers From China | MaiJin Metal

Assembly part by TIG welding process Products | MaiJin Metal

In January 2022, Maijn Metal purchased 20 automatic lathes

Quality MALE FEMALE STANDOFF Manufacturer | MaiJin Metal