Customized Precision Aluminum Alloy Pressure Die Casting Mold Products Supplier

This is an aluminum alloy die-casting product. The surface treatment selected by our customers is an electroplating process. After the surface treatment, the product will look more beautiful. After this aluminum alloy die-casting product is made, it is not so beautiful at the beginning. When the product is die-casted, there will be some excess materials attached to it. In this case, we will polish by hand and machine equipment to remove the excess material. And according to the customer's mold requirements, the product will be tapped and turned, and the surface of the processed product will be beautiful.

Audited supplier

Audited supplierWe have a handmade polishing team and experienced polishing masters to make the castings to increase the beauty of the castings. Improve the corrosion resistance and abrasion resistance of the material surface, more than 50 polished hands, high output, fast and stable shipment. The surface treatment process of die-casting parts is environmentally friendly, and the products are not outsourced. It has its own electroplating factory, the process is environmentally friendly, the product is beautiful, and it improves the wear resistance, conductivity, light reflection and corrosion resistance of the product.

Product features

1. No glitches:It has advanced deburring equipment and reprocessed by hand. Let each product be clean without leaving burrs

2. No deformation: All the polishing masters have more than 10 years of polishing experience, and they have one-to-one training before starting to make the polished products have sharp edges and corners without deformation.

3. No pitting: Owning a surface treatment department, no outsourcing processing is required. The surface treatment of the product selects high-quality materials to make the product shiny and super three-dimensional.

4. Strict standards: Each product is fully inspected according to quality standards, and the delivery rate is high.

Product parameter

| Product application field | Beauty and medical, consumer electronics, smart home, automotive, robotics, communicatins,luggage and other industries |

| Equipment | Zinc alloy die casting machine, aluminum alloy die casting machine, CNC equipment, ultrasonic equipment, polishing machine, grinding machine, automatic tapping machine, etc. |

| Material | Zinc alloy: #2, #3, #5 Aluminum alloy: ADC12, A380, ADC10 |

| Surface Technology | Electroplating, baking paint, powder spraying, sandblasting, electrophoresis, silk screen,wire drawing, laser carving, etc. |

| Surface treatment | Trimming, deburring, deburring, drilling and tapping, polishing, CNC machining |

| Product testing | PCA test, white chrome test, alcohol test, eraser test, salt spray test, hardness test |

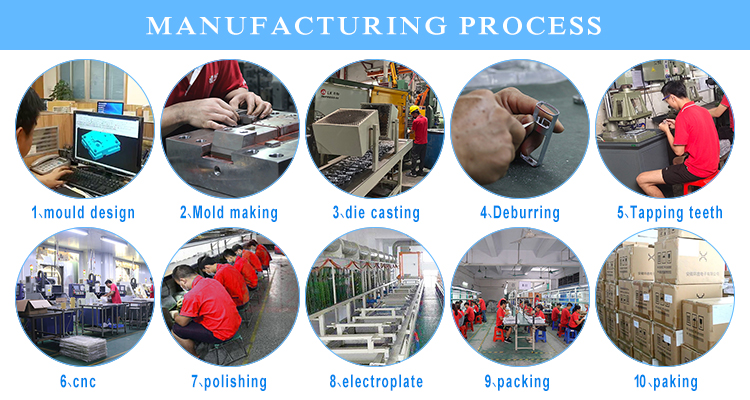

| Production diagram | Drawings or samples → making molds → making samples → casting → deburring →deburring → drilling and tapping → polishing → CNC → surface treatment (plating, baking, sandblasting, powder spraying, or according to customer requirements) → printing Logo → Quality inspection→packaging→delivery |

Our advantage

1. Powerful factory

We are a manufacturer specializing in customization of zinc-aluminum alloy die-casting parts, with 15 years of die-casting production experience, a plant area of 5,000 square meters, 150 production teams, and 10 die-casting machines

2. Strong production capacity, daily output of 20W pieces

10 die-casting machines produce 24 hours a day, with a daily output of 20W pieces

3. Set up independent mold room, mold opening is 2-7 days faster than peers

It has a mold making department and various sophisticated mold manufacturing equipment, and has 3 mold designers with 20 years of experience. Mold opening is 2-7 days faster than the same line

4. Qualification certificate

Won the ISO9001-2015 quality system, RoHS certification

5. One-stop manufacturer

Set up an independent mold room with its own surface treatment department, one-stop production from product mold design to product shipment

Company Profile

Shenzhen Huayin Precision Products Co., Ltd. has focused on the die-casting industry for 16 years. With a plant area of 5,000 square meters, Huayin has a team of more than 200 people. The company specializes in mold design, mold production, zinc-aluminum alloy die-casting, CNC machining, stamping and injection molding.

Our product application areas include: beauty and medical, electronics, smart home, automobiles, robots, communications, luggage and other industries. We can meet any complex requirements of customers in the shortest time. To provide customers with the best manufacturing solutions and quality service is our aim.

Huayin is equipped with a brand new die-casting machine, enabled intelligent automated production, and equipped with the necessary testing instruments in the die-casting industry. During the production process, we have professional project engineers to follow up your products throughout the process, with guaranteed quality and production speed quick.

We sincerely look forward to establishing a happy cooperation with you!

Packing&Shipping

Payment:

Standard payment terms:30%deposit in advance,70% balance before shipment

Online trade assurance order.

More payment terms(T/T,Paypal)

Shipping:

Port:Shenzhen

Time:10-20 working days after payment receipt confirmed

Packing: according to customer's demand ( with pearl-cotton package.)

professional goods shipping forwarder

FAQ

Q. Are you a factory or trade company?

We are a factory with over 16 years in die casting. We service customers zinc alloy 、aluminum alloy die casting、CNC machining、packing、and surface treatment.

Q. How to quote?

We will make the quotation when received the sample or 3D drawing,usually one or two days.

Q. How about your quality?

It passed ISO 9001 Certificate.Operation instruction will be made once the sample is approved.

Q. How about the lead time?

Mold: 3-5 days, Mass production: 30 days.

Q、What is your MOQ ?

We support a small number of sample orders to ensure your recognition of product quality, but the minimum monthly order quantity in the later period is at least 5,000 sets.

Q、Do you offer after-sales service?

We have a professional after-sales team, if you have any quality problems after receiving the product, you can contact us at any time.

If you have any questions, please to contact us !

Audited supplier

Audited supplier

Customized Precision Gravity Die Casting Zinc Alloy Parts

Zinc alloy die-casting beauty instrument accessories

Zinc Alloy Die Casting Parts Manufacturers - Huayin

Aluminum Die Casting Parts Supplier & manufacturers | Huayin

Custom Zinc Die Casting Parts Supplier & manufacturers | Huayin

China Zinc Alloy Die Casting Parts Manufacturers - Huayin

Precision Aluminium Die Casting Parts Supplier & manufacturers | Huayin

Custom Zinc Alloy Die Casting Products | Huayin

Intro to Zinc Alloy Die Casting Services for Customized Industrial Parts Huayin