China Custom high quality dispos plastic, home appliance spoon,fork mould manufacturers - Times Mold

Best Plastic spoon mould Supplier.

The product has been tested with accurate data.

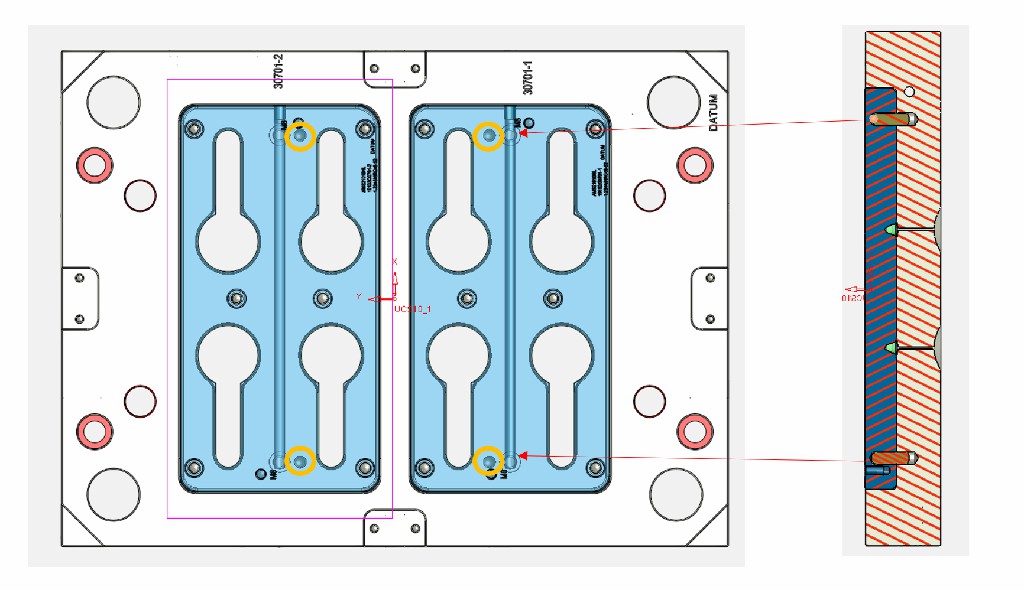

Milk powder spoon mold

Below is compliment from our customer :

" I was just informed by the customer that the Scoop 50ml was tested after delivery in Holland. First results are very good, compliments from customer.

The fitting of the cavity side on the hot half was perfect, dimensions are all correct.

Products look nice, polishing was done good. They need to check product dimensions but they estimate this is not an issue.

customer is happy to hear that also the Lipstick Samplers moulds) are being manufactured at the same toolmaker.

They expect the good quality for these tools as well. And since you take your job in testing and checking the mould

(and also solving the final issues of the powder problem) seriously they are confident of receiving good moulds."

Audited supplier

Audited supplierPart /mould information :

Place of Origin: Shenzhen, China

Shaping Mode: Plastic Injection Mould

Product Material: PP

Product Name: Plastic spoon mould

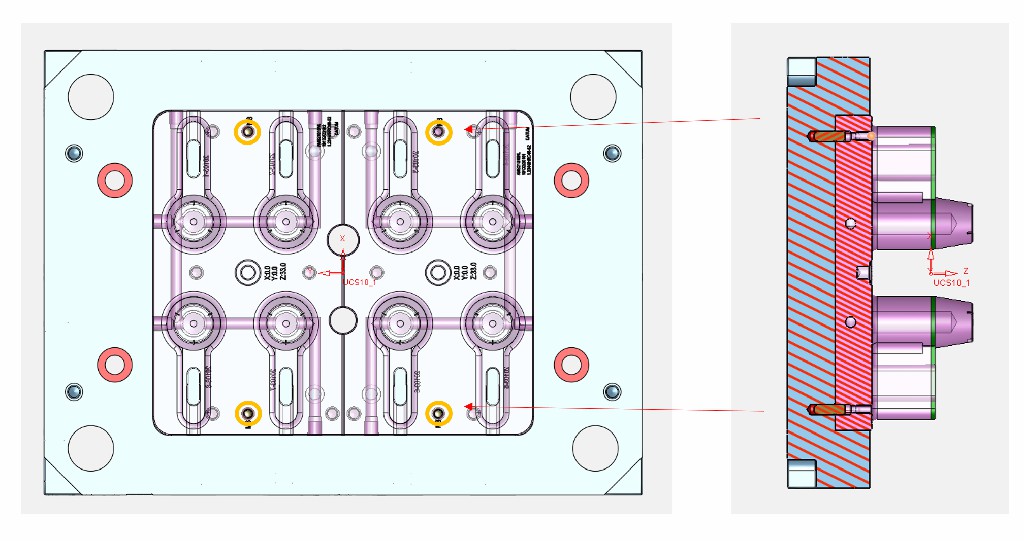

Runner: Hot Runner System

Mould Base: LKM.HASCO.ETC

Mould Life: 100K-1Million Shots

Design: 3D/2D(UG/Pro-e/CAD)

Surface Treatment: Mirror Polish

Lead Time: 25-50 Days

Mould Precision: +/-0.01 mm

Mould Cavity: 1*8 with interchangeable for different versions /spec. of spoons

Multiple Cavity

Mould Material:

Steel

Supply Ability : 300 Sets of moulds / per Year

Packaging & Delivery

Packaging Details : Vaccum Packed / wooden box,or as your requirement

Port : Shenzhen Port

Checking the gap between the core and stripper plate. This must be measured. Also checking if the ejector plate over the cores that the height is not flush, there should be approx. 0.1 mm difference to make sure there is a gap between stripper plate and core (0.01 mm). When there is a gap there will be no sticking anymore.

Audited supplier

Audited supplier

Best Quality automative lighting Supplier & manufacturers | Times Mold Factory

Professional Injection Plastic Mold manufacturers-Mold EDM

One-stop global service manufacturer of plastic injection mold - Mold CNC processing

Reverse mold Supplier & manufacturers for cap | Times Mold Supplier & manufacturers | Times Mold

Best High Quality Plastic Injection Mould - 2k mould/ Products | Factory Price - Times Mold

2K mould VW416 OE Ring LE_MID_RI products Supplier & manufacturers | Times Mold

Gear die

China Custom high quality dispos plastic, home appliance spoon,fork mould manufacturers - Times Mold

POM Gear, Parts & injection mould manufacturer Supplier & manufacturers | Times Mold