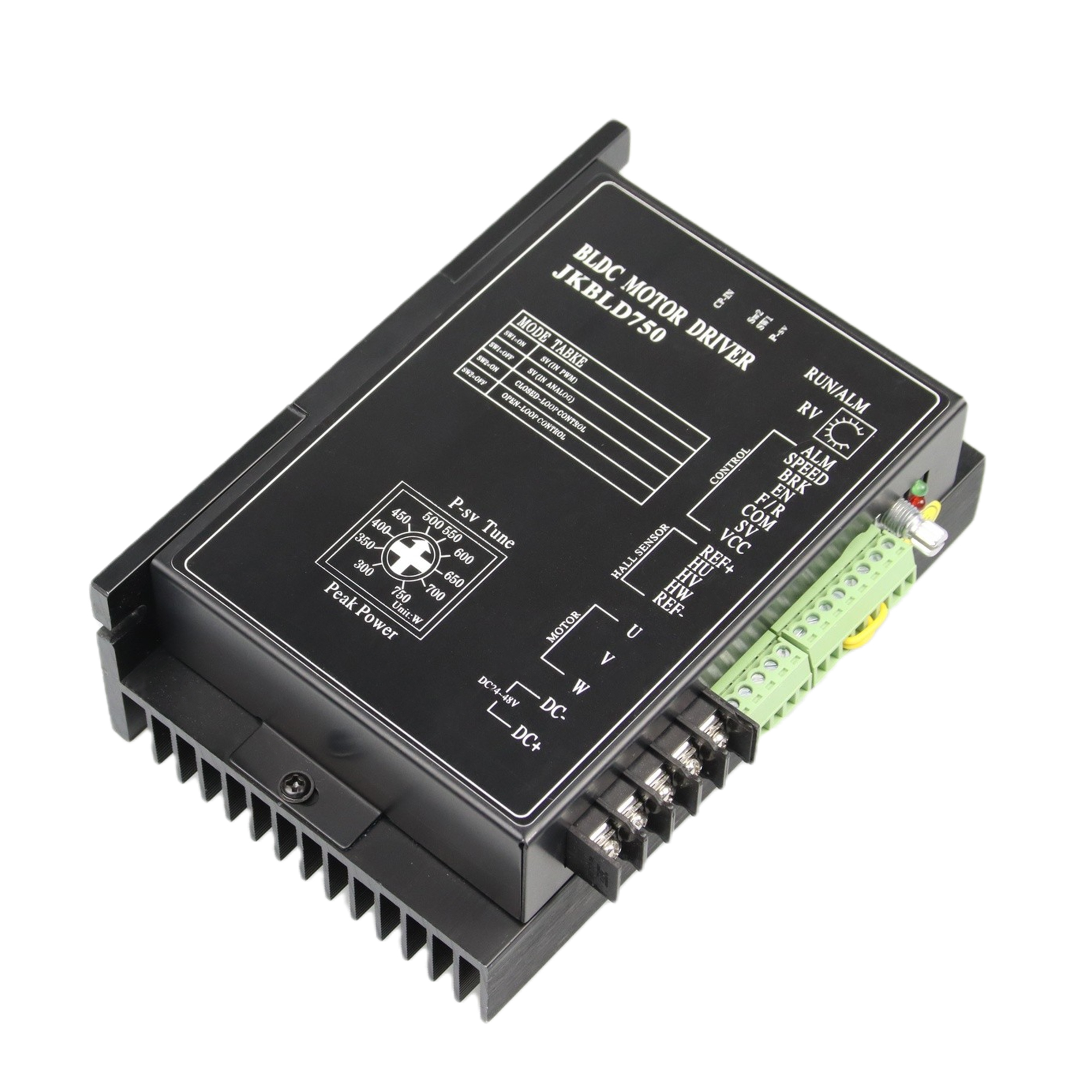

JKBLD750 Brushless DC Motor Driver

Product Type: 750W BLDC Motor Driver

Place of Origin:china

Minimum order quantity:10pcs

Support Motor: Brushless dc motor less of 750w

Packing:The sample is packed in carton,the batch with plastic pallet

Delivery time:Standard product: 7-10days

Customized product: 25-30days

Transaction mode:EXW, FOB, FCA, CIF, FAS, CFR, CPT, CIP, DAF, DEQ, DDU, DDP...

Audited supplier

Audited supplier

Product Overview

The JKBLD750 BLDC motor drive is a high performance, cost-effective 3phase BLDC motor drive, which can provide power output Max 750VA.The design is based on advanced DSP technology and feature high torque, low noise, low vibration, PID speed loop, PID current loop, over current protection, over load protection and a combined use of manual speed adjustment and automatic speed adjustment.

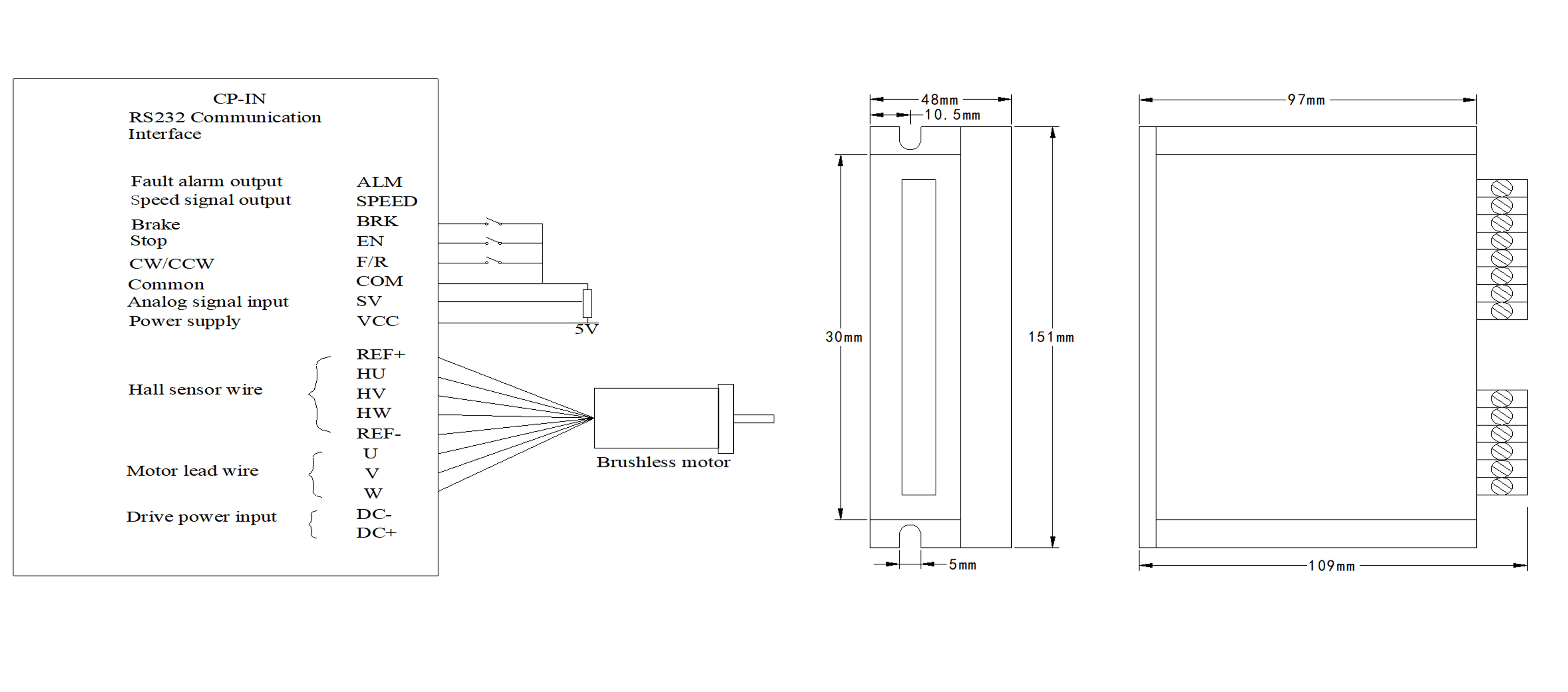

Connection Definition

Mark | Definition |

DC+/DC- | DC Power Input (DC24V~DC48V) |

U,V,W | Motor Lead Wire |

Hu,Hv,Hw | Hall Sensor Lead Wire |

REF+ | Hall Sensor Power Supply + |

REF- | Hall Sensor Power Supply - |

VCC | External Potentiometer Power Supply ( Internal Power Supply Only) |

SV | External Potentiometer ( No Connection When Adjusting Speed With Internal Potentiometer ) or Pulse Rate In Note① |

COM | Common (Low Level/Ground) |

F/R | Direction: Low Level/CCW High Level or No Connection/CW Note ② |

EN | Enable: High Level/Stop Low Level/Run Note ② |

BRK | Quick Brake: High Level/Stop Low Level/Run |

SPEED | Speed Signal Output |

ALARM | Alarm Signal Output |

Note①: Potentiometer/10KΩ or analog signal DC 0V~+5V (Change

internal switch J1/DC0-10V).Turn off the internal potentiometer RV

when using an external potentiometer to adjust the motor speed.

Note②:High level/5V (5mA)

Parameter | Min | Rated | Max | Unit |

Motor Hall Sensor Angle | 120°/240° |

| ||

DC Power Input | 18 | 48 | 50 | V |

Drive Current Output | 0 | 25 | 45 | A |

Suitable Motor Speed | 0 |

| 20000 | rpm |

Hall Sensor Voltage | 4.5 | 5 | 5.5 | V |

Hall Sensor Current |

| 20 |

| mA |

External Potentiometer |

| 10K |

| Ω |

●Motor Speed Adjusted By The Internal Potentiometer RV:

SW1/ Off (Factory setting)

●Motor Speed Adjusted By Analog DC 0V~+5V Input:

SW1/ Off (Factory setting) set J1 (internal) as (user Setting) RV—Turn Off

● Motor Speed Adjusted By Analog DC 0V~+10V Input:

SW1/ Off (Factory setting) set J1 (internal) as (user Setting) RV—Turn Off

● Motor Speed Adjusted By Pulse Rate Input:

Pulse rate: 0K—3KHZ Speed linear modulation

Pulse amplitude: 5V Pulse duty ratio: 50%

SW1/ On (User setting) RV—Turn Off

J7 (Internal)/ Switch on with the jumper cap on J1 (User setting)

● Motor Speed Quick Response Setting:

SW2/ On ( User setting): PID closed loop--quick speed response

SW2/Off (Factory setting): Open loop--Normal speed response

● Motor Speed Signal Output:

Connecting SPEED and COM to get pulse output F=N*P/60

F—Pulse output frequency

P—Pole number of BLDC motor

● Drive Alarm Output:

When drive alarm, it will break over with the port of COM and be low

level. The drive stop to work and alarm light run.

Lead Wire Connection: Take care of the sequence of U,V,W

Motor Parameter set by ICAN BLDD-01 (Optional) :

●RS232 Communication Interface CP-in

The BLDD48-45A BLDC motor drive support RS232 communication Protocol to set motor run-up time, etc. When choose ICAN BLDD-01 as host controller, the operating process and instruction as below:

●ICAN BLDD-01 Motor Setting Panel Operating Process:

Connect to CP-in (BLDD48-45A)

SW1/ Off (Factory setting) RV—Turn Off

BLDD-01 Parameter Setting Table:

Function code | Mode | Setting range | Unit | Factory setting | Alteration |

P000 | Control mode | 00 BLDD-01 control |

| None Panel control | ★ |

P001 | Panel setting speed | 0~Rated speed | RPM |

| ★ |

P002 | Run-up time | 0.1~9.9 | S | 0.2 | ★ |

P003 | Motor pole number setting | 1~99 | Pole pairs | 4 | ★ |

P004 | CW CCW | 01 CW |

| 01 | ★ |

P005 |

|

|

|

| Reserved |

P006 |

|

|

|

| Reserved |

● BLDD-01 Panel Setting Process:

1. Turn on the power supply, press <Set> to stop the motor

2. Press <▲> or <▼> to choose the mode you need (Press Esc return and motor running)

3. Press <Set> enter into parameter mode (Press Esc return and motor running)

4. Press <> or <> to change the parameter (flashing)

5. Press <Set> to reserve, parameter stop to flash. Press <Esc> return and motor running.

Panel Protection Mode:

When the system running, panel nixie light shows Err×

Err0 represents Over-voltage or Over-temperature protection

Err1 represents Over-current protection

Err2 represents Hall sensor error protection

●Motor Parameter set by other host controller:

BLDD48-45A Communication Protocol (RS232)

1. Communication Interface:

Asynchronous serial communication

Baud rate:2400

Start bit:1 bit

Stop bit:1 bit

Data bit:8 bits

Even/odd parity:none

Communication interface voltage:3.3V

2.Communication Protocol:

Function1:Motor speed controlled by drive BLD-750 itself

Communication format :“i”

Instruction:send a character

Function2:Motor speed controlled by host computer

Communication format:“o”

Instruction:send a character

Function3:Motor speed set by host computer

Communication format:“v”0X00,0X00

Instruction:send a character “v” then two hexadecimal numbers

the high 16bits,the low 16 bits

Function4:run-up time

Communication format:“y“ 0X00

Instruction:send “y“ then a hexadecimal number

Audited supplier

Audited supplier

1.8°Nema 34 Linear Stepper Motor 86x86mm for for 3D printer CNC Engraving Milling Machine

1.8° Nema 14 Hybrid Stepper Motor 35x35mm 0.5A or 1A with 4leads

1.8° Nema 34 Hybrid Stepper Motor 86x86mm with 4leads or 6leads

1.8° Nema 16 Hybrid Stepper Motor 39x39mm with 4leads or 6leads

1.8 Degree Nema 11 Hybrid Stepper Motor 28x28mm 0.67A or 0.95A With 4leads or 6leads

0.9° 36mm 2-Phase Hybrid Round Stepper Motor 36x36mm With 4leads

1.8° Nema 24 Worm Gearbox Stepper Motor 60x60mm for CNC Milling

1.8° Nema 24 HSG Eccentric Gearbox Stepper Motor 60x60mm for CNC Milling

1.8° Nema 24 HSP Planetary Gearbox Stepper Motor 60x60mm for CNC Milling