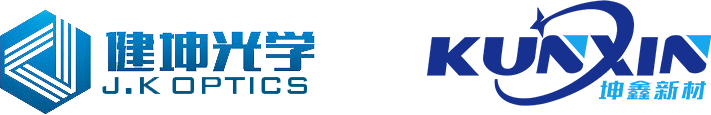

DIFFUSER SHEET FOR LED LIGHTING

WELCOME TO J.K OPTICS

J.K OPTICAL PLASTIC CO.,LTD is a group with two factory and two brand, it's "J.K Optics" & "KunXin Material",which specialize in optical plastic sheet manufacturing & Textured acrylic sheet separately, has been serving the lighting industry & decoration market for almost 10 years, products included: Acrylic diffuser sheet, PC diffuser, PS diffuser, Acrylic textured/pattern plate, and optical PMMA & PC sheet/film, it's widely used in Fluorescent light fixtures, Led panel light, Ceiling light & architectural applications and display panels,digital photo frames.

Audited supplier

Audited supplier

PMMA/PC/PS Diffuser Sheet for LED LIGHTING

1, Light Transmission: Normally 90%、85%、80%、76%、60%, can tailor to customer's requirements

2, Appearance: One side matte, another side smooth;one side matte, another side orange peel texture;

3 ,Outstanding LED Hiding Ability

4, Easy To Fabricate

5, Environment Friendly

6, OEM/ODM Customizable

DESCRIPTION

Excellent Selection Of 100% Virgin Material & Unique Formula

Base on the optical theory, the Led diffusion sheet is produced with Optical grade PMMA raw material and scientific formula processing,

the light can be reflected and refracted and scattering in the chemistry particles and resin continuously to achieve the best light transmission

and excellent Led hiding ability and Increases light uniformity throughout the lighting diffuser

Excellent Optic Diffusion Performance & EfficiencyLED Lighting Diffuser enable high efficiency extraction of light from a luminaire without

sacrificing performance. Transmission well in excess of 90% is typical, and luminaire dependent efficiency can be even higher.

Strong illuminant Hiding Ability

Lighting diffuser offer outstanding hiding of LED and fluorescent light sources, with excellent color mixing. The diffuser solve the most difficult

LED hiding problems while maintaining excellent efficiency.

Matte surface & Orange Peel Texture

Matte Surface for one side or Orange Peel Texture side specifically designed for LED panel light, downlight and so on, it features a unique combination

of high light diffusion and high light transmission through a combination of optimized surface texture and advanced diffuser technologies. Increases

light uniformity throughout the lighting diffuser;

Application:

Our diffuser sheet being widely used for the panel light, Down light, linear light and so on, that's because our diffuser sheet with different levels of

light diffusion to meet various fixture performance requirements. "Some designs, for example, may want a low level of diffusion to soften the edges

of emitted light. Others may need more light diffusion to reduce direct glare. Also, variables such as the LED-to-lens distance and the LED matrix spacing

affect the optimal light diffusion. While diffusion and light transmission are directly associated, having these diffusion options allows the light fixture

designer the ability to achieve the lighting qualities they desire for a specific fixture."

J.K has got over 10 years in Polycarbonate sheets and Acrylic Sheets manufacturing and supplying, and successfully achieved two brand "J.K Optics" & "KunXin

plas", which specialize in optical Acrylic / Polycarbonate diffusion sheet manufacturing & Textured acrylic panel separately , has been serving the lighting industry

& decoration material market for almost 10 years, products included: Acrylic diffuser plate, PC diffuser film, PS diffuser sheet, Acrylic textured/pattern panel, and

optical PMMA & PC sheet/film, it's being widely used in Led light fixtures, Led panel light, Ceiling light; architectural applications and display panels,digital photo f

rames.......

So far we have introduced advanced Co-extrusion equipment, and raw material we only use "Mitsubishi" from Japan and "Qimei" from Jiangsu, The key manufacturing

procedures of extrusion, calendaring, cooling, and masking film are all completely in dust-free condition. The production lines are fully automatic and controlled by

computer, and now is one of the leading companies in the optical plastic industry in china, which monthly process capability reach to 600 tons, and share a large market

in china. As a commitment to our customers, Kunxin company continues to re-invest heavily in research and development along with the very latest technology in our

plants,for a continued stream of new products, quality and cost control. This enables Kunxin company to assist our customers in meeting the everyday challenges in an

ever changing global marketplace.

Our goal is to satisfy our customers with high precision and reliable quality to

ensure that every customer can feel comfortable and confident with our goods in

their applications.

We are committed to producing the best quality products at the most competitive

prices. Therefore, we sincerely invite all interested companies to contact us for more information.

Audited supplier

Audited supplier

Acrylic sheet, diffuser sheet, PMMA Acrylic sheet for lighting .

PMMA ACRYLIC HONEYCOMB SHEET

PROFESSIONAL MANUFACTURER OF ACRYLIC DIFFUSER PRISMATIC SHEET

TEXTURED ACRYLIC SHEET

DIFFUSER SHEET FOR LED LIGHTING

Professional manufacturer of optical plastic sheet J.K OPTICS

PMMA/PC PRISMATIC DIFFUSER

PROFESSIONAL MANUFACTURER OF LED DIFFUSER SHEET

DIFFUSER SHEET FOR LED LIGHTING