How To Make Sure The Clean Room Work Successfully

SUZHOU PHARMA MACHINERY CO.,LTD.2023-03-270 views

Ensure the purification of materials entering the clean room

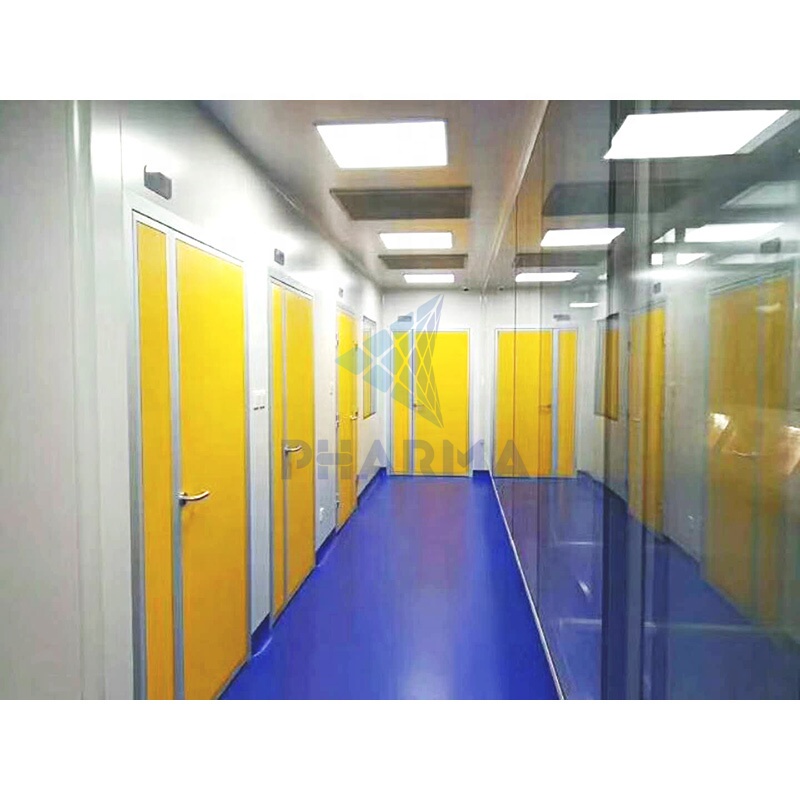

Materials entering the clean room shall be cleaned and purified before being transported into the clean room, so as to reduce the amount of dust generated by materials in the clean room. Small items entering the clean room generally enter through the transfer window between the clean room and the outer corridor or between the clean rooms (adjacent rooms with different cleanliness levels).

Ensure that the air entering the clean room is clean

During the operation of the purification air conditioning system, the air filters at all levels used must be intact without damage or leakage. In order to prevent the air supply system from bringing dust particles that should not enter the room into the room, it is necessary to regularly check the leakage of the primary, medium and end air filters used in the system.

Ensure the air supply volume of the purification air conditioning system

To ensure the air supply volume of the air conditioning system is to ensure the number of air changes in the clean room to meet the needs of indoor air distribution. During the normal operation of the purification air conditioning system, the air supply volume of the system should be measured regularly. The measuring points can be selected at the inlet (outlet) of the air supply fan and the air supply outlet. Because the air supply volume of the system is comprehensively considered in terms of energy consumption, indoor air distribution and other aspects. If the air supply volume of the system is too low, the air flow velocity at the air supply outlet in the clean room will be reduced, thus damaging the indoor air flow organization form, making the indoor polluted air unable to be discharged, and failing to meet the indoor cleanliness level required.

Ensure the positive and static pressure in the clean room as required.

During the operation of a clean room, it is generally required to maintain a certain positive and static pressure difference between the clean room and the adjacent room and corridor (including the outer corridor), that is, the static pressure value of the clean room is higher than that of the adjacent room (rooms with different cleanliness levels) and corridor, so as to avoid pollution caused by the air outside the clean room with high dust concentration such as the adjacent room and corridor. Therefore, during the operation of the clean room and purification air conditioning system, attention should be paid to the regular inspection, maintenance, adjustment and repair of the residual pressure valve in the system, as well as the pressure sensor, transmitter, regulator and actuator, so as to keep them in normal operation and maintain the required positive and static pressure in the room

Suzhou Pharma Machinery Co.,Ltd.

2023/03/15

David

You may also like

Automatic disposable inner ear loop surgical face mask making machine production line YQWD 100

Full Automatic High Speed KF94 FISH FACEMASK-YQWD 50

Noodle macaron pasta automatic weighing and packing machine

how to dry tobacco by IKE drying room

V type Linear Combination Weigher- Carrots Machine

New! Fish Weigher 18 Head Combination Multihead Weigher

Stick Jelly Multihead Weigher

Smart Weigh Dried Fruit Doypack Packing Machine And System

Mushroom & Liquid Preformed Bag Packing Line

Shredded Cheese 14 Head Multihead Weigher