China Heat Resistant Plastic Injection Mold Parts HKH Heat Sink Pipe manufacturers -

China Heat Resistant Plastic Injection Mold Parts HKH Heat Sink Pipe manufacturers -.

The fabric that this bedding is made of can regulate users' body temperature and help them sleep through the static.

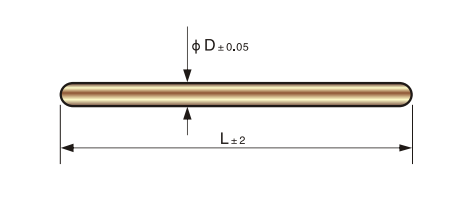

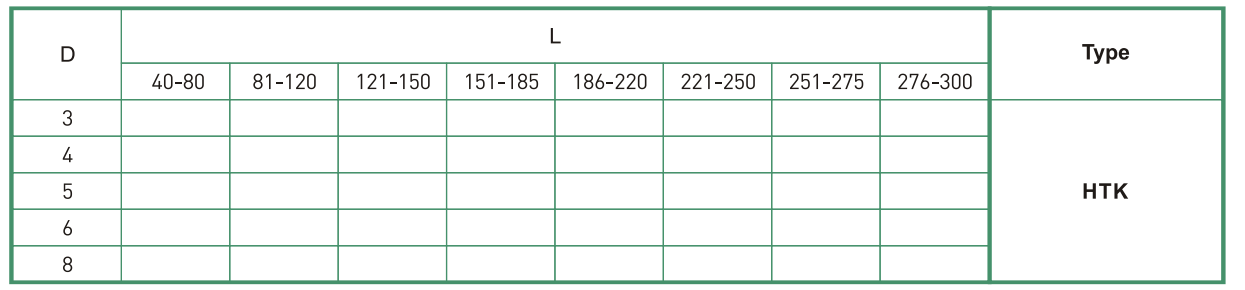

Technical specifications

Product Name: Heatsink

Material: copper+ cooling liquid

Size: According to the standard

Type: HTK

Audited supplier

Audited supplierThe fabric that this bedding is made of can regulate users' body temperature and help them sleep through the static.

Technical specifications

Product Name: Heatsink

Material: copper+ cooling liquid

Size: According to the standard

Type: HTK

Technical specifications

Product Name: Heatsink

Material: copper+ cooling liquid

Size: According to the standard

Type: HTK

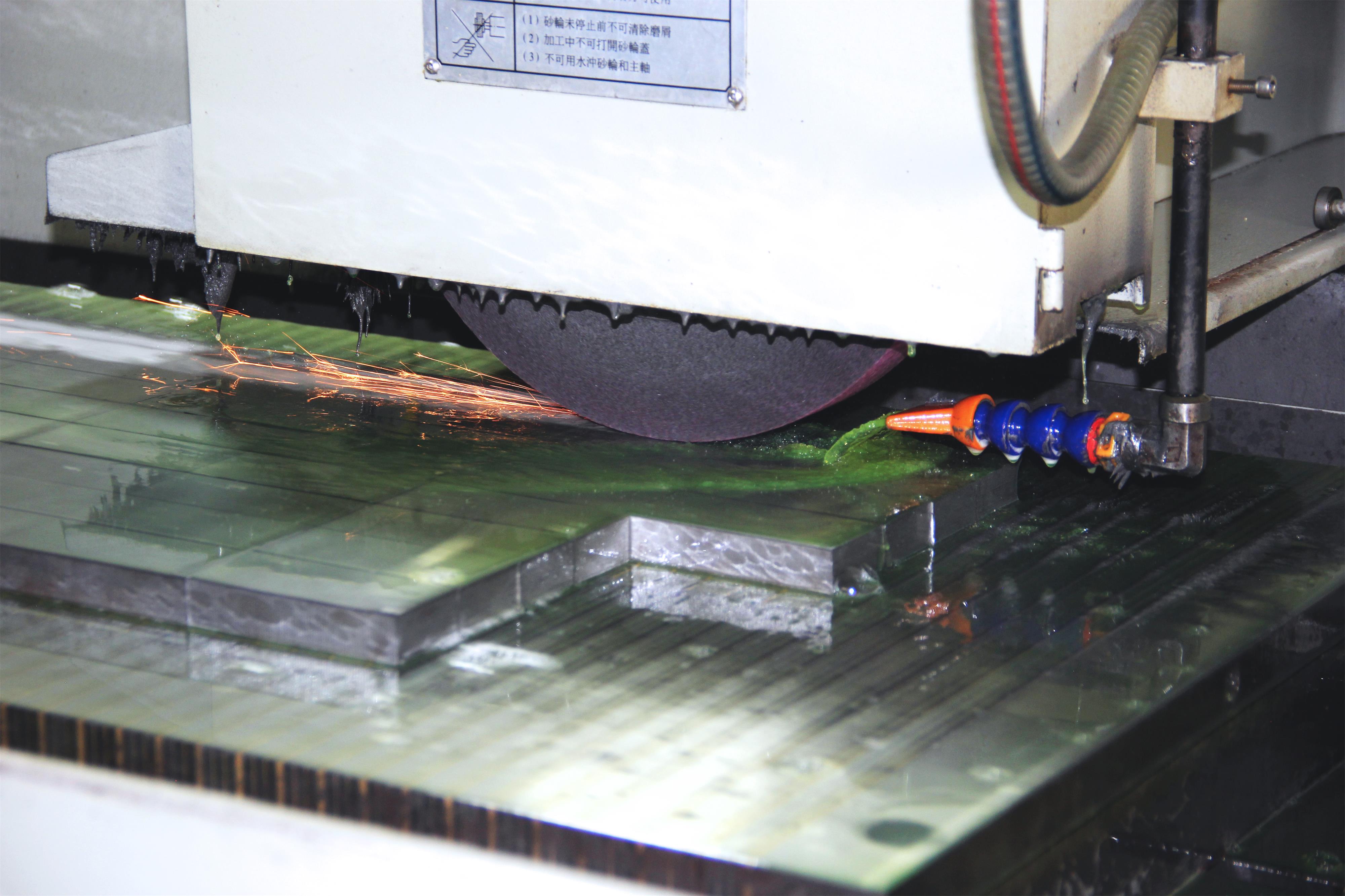

Advantages of heat pipe method:

1. The forming cycle can be shortened by more than 30% (high-speed heat absorption and cooling)

2. A molded product with less residual stress can be obtained (to prevent product shrinkage and deformation)

3. The precision of the formed product is good (the cooling water is boiling)

4. The outer surface of the molded product is good (to prevent the generation of scale)

5. It can reduce the phenomenon of uneven color (can be operated for a long time)

6. Mold maintenance is very effective, so accuracy can be maintained and labor is reduced.

7. Only need to install the additional heat pipe, then the mold can be improved.

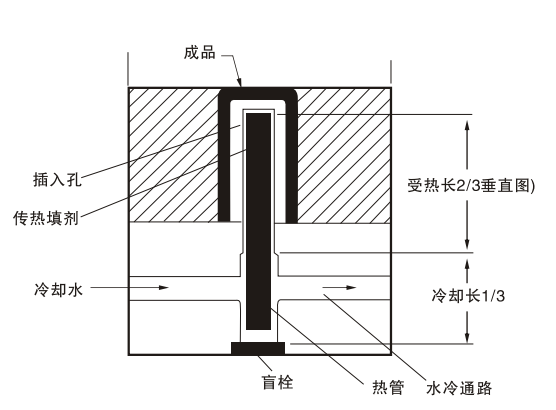

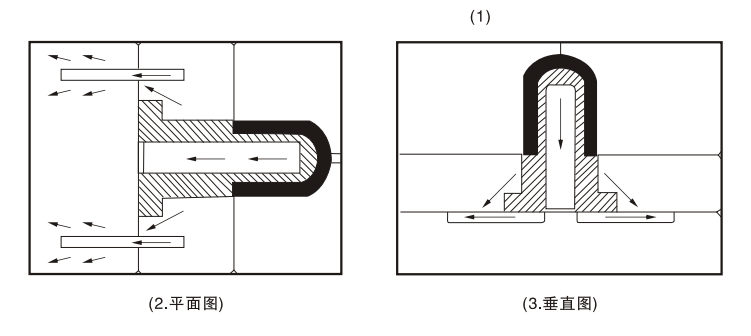

Installation method:

1. The hole diameter of the cooling pipe should be 0.1m/m-0.2m/m larger than that of the cooling pipe.

2. After the cooling pipe is installed, please fill the more space with heat transfer filler.

3. The bore diameter of the cooling water channel should be more than twice as large as the cooling pipe.

4. When installing the cooling pipe, please embed 1/3 or 2/3 of the total length of the cooling pipe into the mold

Within to ensure safety.

5. The heat pipe cannot be cut off and disassembled by fingers, nor can it be bent or flattened.

Audited supplier

Audited supplier

Customized Non-standard mold parts For plastic injection Mold manufacturers From China | BAITO

Quality Non-standard mold parts For plastic injection Mold Manufacturer | BAITO

Customized Non-standard mold parts For plastic injection Mold manufacturers From China | BAITO

Best Non-standard mold parts For plastic injection Mold Company - BAITO

Best Non-standard mold parts For plastic injection Mold Company - BAITO

Best Non-standard mold parts For plastic injection Mold Company - BAITO

Customized Non-standard mold parts For plastic injection Mold manufacturers From China | BAITO

Customized Non-standard mold parts For plastic injection Mold manufacturers From China | BAITO

Quality Non-standard mold parts For plastic injection Mold Manufacturer | BAITO