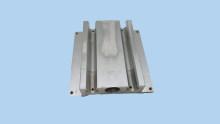

High End Precision Extruded CNC Machining Anodizing in Champagne 5G Equipment Aluminum Profile

2 years ago

237

Share

This is high end precision extruded CNC machining anodizing in champagne 5G equipment aluminum profile.

Our factory equipment protection fence is a fence formed from the main frame structure, a wire mesh, a computer board, an acrylic panel, by an industrial aluminum profile. In the process of processing of aluminum alloy, it is prone to sticky knives, tapping breaks, surface molds. Such equipment guards are generally built in the periphery of the production equipment, and is used with the alarm and terminal equipment. Function is to divide the workshop area, prevent the operator from contacting the device directly, and play a safety warning!

Customers use ordinary columns to save costs, bolts and corners are connected in the middle. Secure anchor connector with an expansion screw. Beautiful and firm!

Aluminum profile processing process

1. Squeeze processing: There is no doubt that aluminum type material heat exchanger is a shaped aluminum profile, which requires mold opening. After designing the mold, it is processing aluminum profile;

2, CNC finishing: Aluminum profile radiator is very high for accuracy, which requires CNC finishing, Our CNC processing can achieve ± 0.01 mm accuracy;

3. Surface treatment: surface treatment is also an indispensable processing step of aluminum profiles. After the surface treatment, the aluminum profile can be lustrous and corrosion.

Characteristics of aluminum alloy display box:

1.All-aluminum alloy material, four sides can be opened, convenient to change, easy to carry, simple installation;

2.Aluminum alloy profiles relative to other materials, the cost price is very low, the price is relatively high;

3.Frames use plane 90 degrees bright corner design, appearance, generous fashion, high advertising art effect,

4.Applicable ranges are relatively wide, such as catering service information, construction site construction, China Mobile communications, shopping mall display information, campus culture publicity, hospital display promotion, etc.

Here are 4 great advantages of Guangdong Aluminum Application Precision Technology Co.,Ltd as following . Strength creation quality:

01

Professional production equipment shorten delivery cycle

Our company has extruded machines, gantry milling, CNC machining centers, drilling machines, tapping machines, latches, etc., can be produced from aluminum to processing one-stop service.

02

The product is tailored to pursue excellence

Our company's various products produced are close, excellent in quality, and create high quality services to customers. Our focus and persistence, serve every new and old customers.

03

Intimate service, let you rest assured

Our company has an efficient and dedicated team, pursuing perfect professionalism, and meticulous services to solve the pre-sale, sale and after-sales issue.

04

Create excellent service tenet

Our company adheres to the business philosophy of customers, the service and equipment is based, abide by: pragmatic innovation, pursuing excellent corporate spirit.

Here answering the common problem:

Order process:

1. Sample or drawings - Project Evaluation - Quote - Customer Confirmation - Signing Contract - Engineering CAD Drawings - Customer Confirmation Drawings Signature Back - Payment Mold - Mold Production - Confirm Sample - Batch Production

2. Batch production - pay 30% prepayment - production - shipping payment

Minimum order quantity: depending on the size of the mold

Production cycle: open mold: 7-15 days, depending on the size of the mold. Production products: 12-20 days

Payment method: Prepaid 30% deposit during order, 70% balance before delivery.

Our factory equipment protection fence is a fence formed from the main frame structure, a wire mesh, a computer board, an acrylic panel, by an industrial aluminum profile. In the process of processing of aluminum alloy, it is prone to sticky knives, tapping breaks, surface molds. Such equipment guards are generally built in the periphery of the production equipment, and is used with the alarm and terminal equipment. Function is to divide the workshop area, prevent the operator from contacting the device directly, and play a safety warning!

Customers use ordinary columns to save costs, bolts and corners are connected in the middle. Secure anchor connector with an expansion screw. Beautiful and firm!

Aluminum profile processing process

1. Squeeze processing: There is no doubt that aluminum type material heat exchanger is a shaped aluminum profile, which requires mold opening. After designing the mold, it is processing aluminum profile;

2, CNC finishing: Aluminum profile radiator is very high for accuracy, which requires CNC finishing, Our CNC processing can achieve ± 0.01 mm accuracy;

3. Surface treatment: surface treatment is also an indispensable processing step of aluminum profiles. After the surface treatment, the aluminum profile can be lustrous and corrosion.

Characteristics of aluminum alloy display box:

1.All-aluminum alloy material, four sides can be opened, convenient to change, easy to carry, simple installation;

2.Aluminum alloy profiles relative to other materials, the cost price is very low, the price is relatively high;

3.Frames use plane 90 degrees bright corner design, appearance, generous fashion, high advertising art effect,

4.Applicable ranges are relatively wide, such as catering service information, construction site construction, China Mobile communications, shopping mall display information, campus culture publicity, hospital display promotion, etc.

Here are 4 great advantages of Guangdong Aluminum Application Precision Technology Co.,Ltd as following . Strength creation quality:

01

Professional production equipment shorten delivery cycle

Our company has extruded machines, gantry milling, CNC machining centers, drilling machines, tapping machines, latches, etc., can be produced from aluminum to processing one-stop service.

02

The product is tailored to pursue excellence

Our company's various products produced are close, excellent in quality, and create high quality services to customers. Our focus and persistence, serve every new and old customers.

03

Intimate service, let you rest assured

Our company has an efficient and dedicated team, pursuing perfect professionalism, and meticulous services to solve the pre-sale, sale and after-sales issue.

04

Create excellent service tenet

Our company adheres to the business philosophy of customers, the service and equipment is based, abide by: pragmatic innovation, pursuing excellent corporate spirit.

Here answering the common problem:

Order process:

1. Sample or drawings - Project Evaluation - Quote - Customer Confirmation - Signing Contract - Engineering CAD Drawings - Customer Confirmation Drawings Signature Back - Payment Mold - Mold Production - Confirm Sample - Batch Production

2. Batch production - pay 30% prepayment - production - shipping payment

Minimum order quantity: depending on the size of the mold

Production cycle: open mold: 7-15 days, depending on the size of the mold. Production products: 12-20 days

Payment method: Prepaid 30% deposit during order, 70% balance before delivery.

Comments

No comments received

Suppliers

Guangdong Aluminum Application Precision Technology Co., Ltd.

Audited supplier

Audited supplierChina3YRS

Road 5, Jihua Road, Chancheng District, Foshan City, Guangdong Province, China

Product details

Comments

Suppliers

Guangdong Aluminum Application Precision Technology Co., Ltd.

Audited supplier

Audited supplierChina3YRS

Road 5, Jihua Road, Chancheng District, Foshan City, Guangdong Province, China

You may also like

AL Aluminum丨OEM Aluminum Extrusion Aluminium Heat Sink High Precision Quality Cylindrical Sun Flower Aluminum Heat Sink

Ali Home Video

Custom Precision Led Aluminum Profile Radiator LED Sunflower Aluminum Profile Radiator

High Precision Quality Industrial Aluminum Alloy Electric Heating Towel Rack Bracket Aluminum Profile

High Precision Quality Customized Laser Marking Machine Aluminum Profile

High End Precision Quality Jewelry Showcases Aluminum Profiles Parts Cases Frame

OEM Custom Aluminum Alloy Die Casting LED Lighting Housing

High Precision Quality Cylindrical Sun Flower Aluminum Heat Sink Led Aluminum Profile

Aluminum Alloy Panel Customized Stamping Processing Customized Aluminum Alloy Keyboard Base