How Do Hot Melt Glue Work?

What is a hot-melt glue?Let's start at the beginning!

Audited supplier

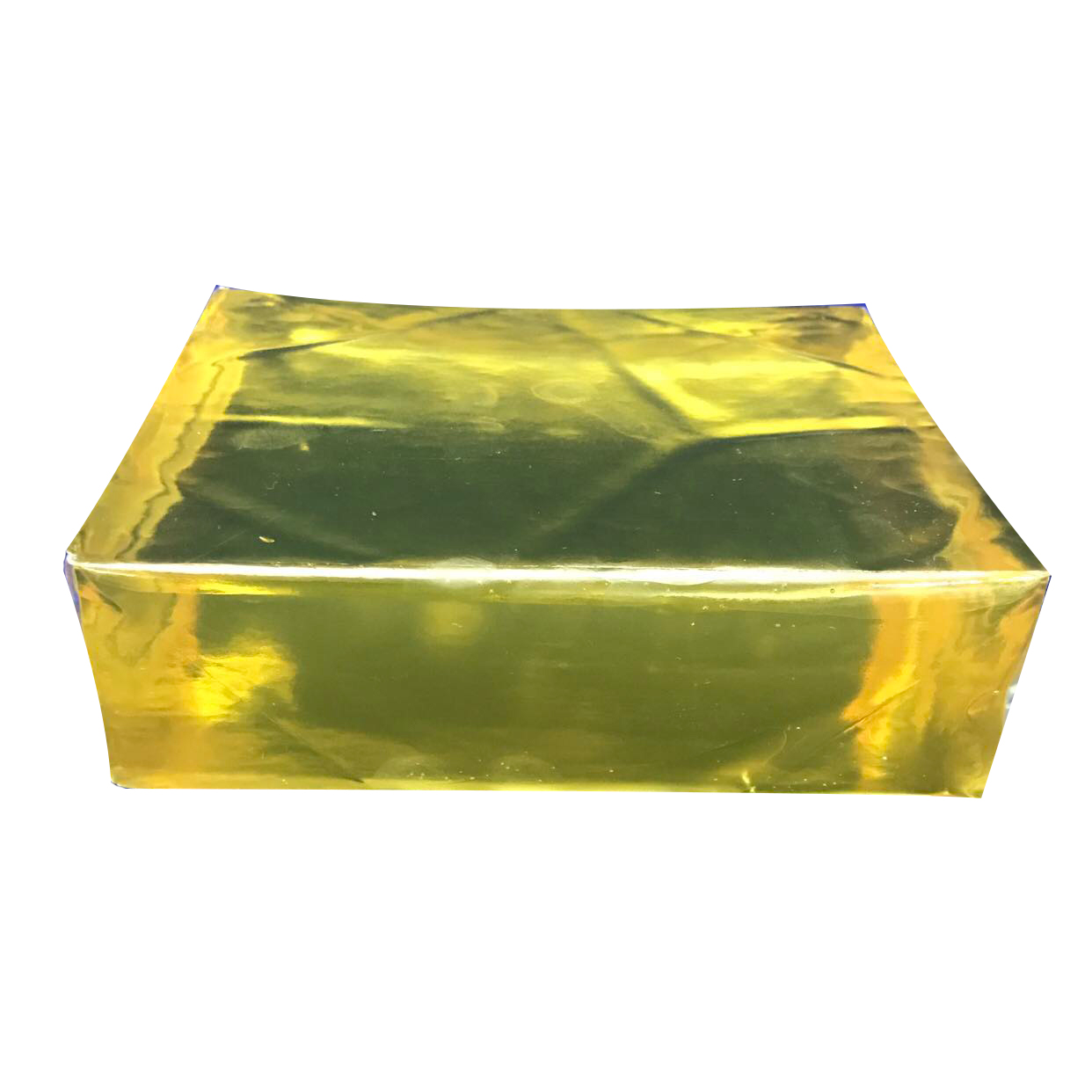

Audited supplierHot melt glue is a very important raw material for baby diapers, sanitary napkins, underpads, and adult diapers. The video can show you how is hot melt glue working.

What hot melt adhesives made of?

Hot melt adhesives are 100% solid and contain no solvents and no water and our instant bonding. They set by the loss of heat which gives them a very fast setting speed. They can Vaughn both similar and dissimilar materials. Polymers give the adhesive strength and the degree of flexibility. Resins give a major hot tap of the adhesives. Wax thins the adhesive so that it can be applied an antioxidant help preserve the adhesive at high temperatures.

So how do hot melts work?

Hot melt adhesives are applied to a material in a liquid or molten state. The time between applying the adhesive and then bringing the second material in contact is called open time. When the second material is brought into contact the adhesive cools down and solidifies very quickly. Compression of materials is very important at this stage.

What effects adhesion as hot melt adhesive set by the loss of heat?

The temperature at which they are applied is critical. It must be liquid or molten enough to wet out the substrates and be hot enough for assembly before cooling. If the adhesive is not hot enough in the molten stage, a bond may be made which will fail at a later stage which is called a cold one.

On the other hand, if the adhesive is applied at to higher temperature will remain molten for too long and may come out of the compression stage still soft. Any stress on the bond will then cause failure immediately or produce a weakened bond that will fail at a later stage. Hot melt adhesives such as EBA, acrylic, polyamide, polyolefin, or thermoplastic products and melt with each and set solid by the loss of heat. This is an important fact to consider when selecting a grade. Do you need a high heat-resistant will the glue line be exposed to the heat of direct sunlight.

What about water?

Standard hot melt adhesives such as EBA, acrylic, polyamide, polyolefin are not waterproof, and applications involving water should be avoided. Hot melt adhesives are not recommended for external use. However, polyurethane adhesives cross-laid once cured offer excellent heat and chemical resistance and can even be dry-cleaned and used externally.

Application tips

Materials being bonded must be clean dry and free of dust oil and grease. Hot melt adhesives must be applied at the correct temperature. The temperature of the materials and surroundings can affect perfusion. Too hot and the adhesive takes too long to set. Too cold and the adhesive sets before the materials are bonded. The amount of adhesive applied will greatly affect the body. Too little and the adhesive will cool more quickly perhaps before the bond has been made properly. Too much adhesive prevents the bond from cooling down before coming out of compression allowing it to come apart.

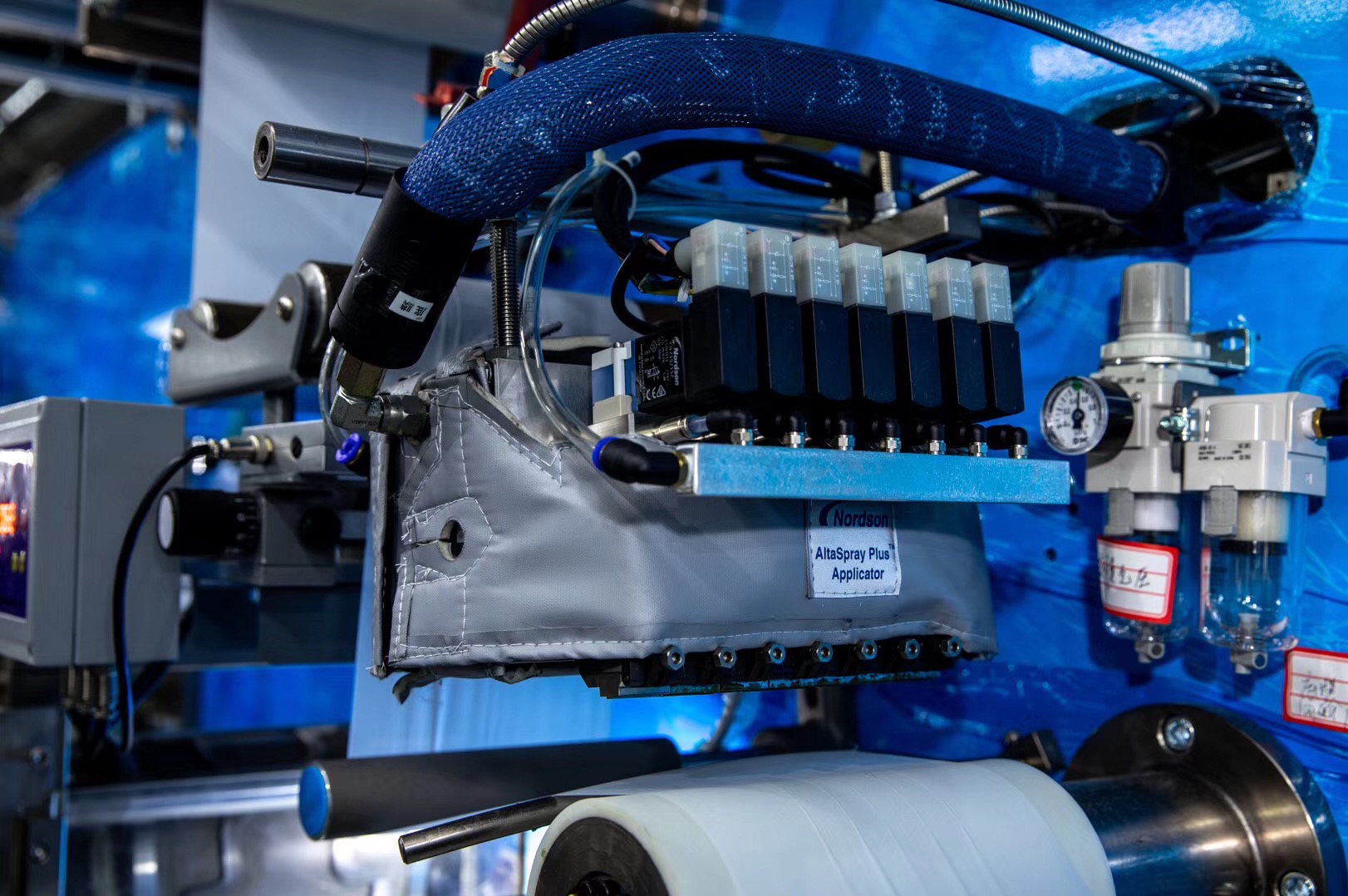

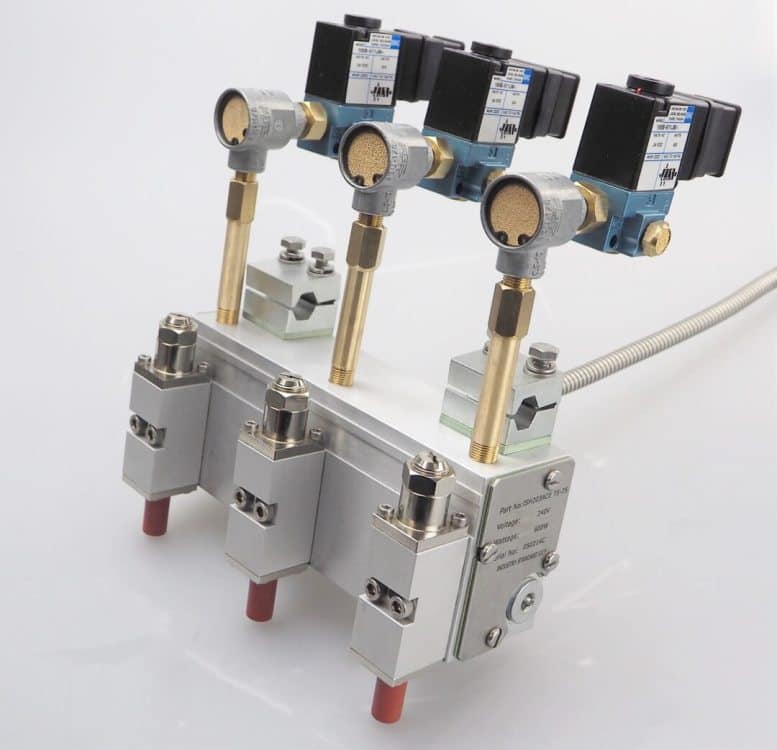

Hot melt glue is a very important raw material for baby diapers, sanitary napkins, adult diapers, and underpads. It is different from normal hot melt adhesives. Also required high precision glue system to spray it. We QZWXM use a high-performance glue system to keep the machine stable running. It can save the raw material and keep producing good quality.

This is Quanzhou Wanxiang Machinery Manufacturing Co., Ltd(QZWXM) 2021 catalog. Our products include a professional production line of baby diapers (I&T diaper, baby pant, full waistband diaper), adult diapers production line (adult diapers, adult pants), sanitary napkins (pulp fluff and ultra-thin), and panty liner production line, underpad and pet training pad production line, disposable breast pad production line and mask (included face mask and 3D mask) machine.

Audited supplier

Audited supplier

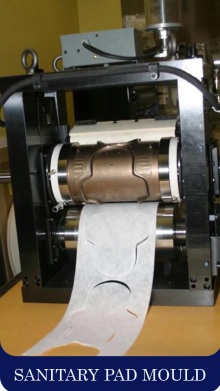

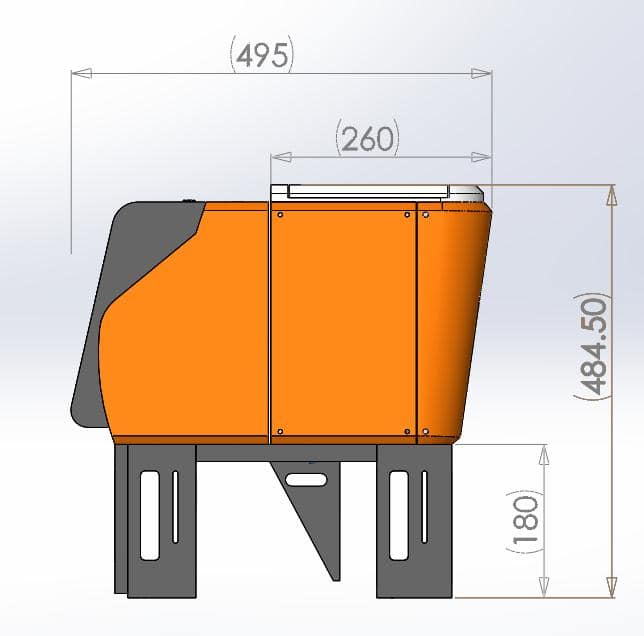

Cut or Embossing Roller

adult diaper machine

adult diaper machine customer review

China domestic pension institutions call for: advocate the use of high-quality adult diapers

THE DEVELOPMENT AND UTILIZATION OF POLYMER ABSORBENT RESINS (SAP) IN DIFFERENT FIELDS

the epidemic prevention glow mask is coming, and the place where the virus is attached to the mask will glow!

Four packing solutions for baby diaper manufacture

what you should know about panty liner machine

Development of baby diaper core structure