Screen Printing Machine for Socks

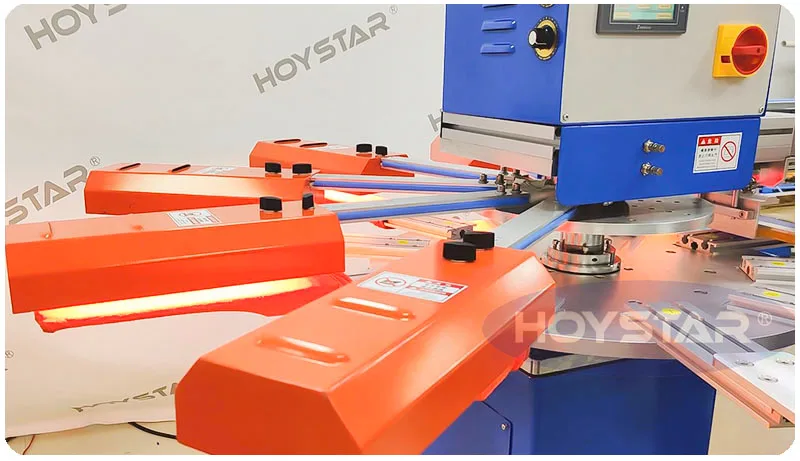

Anti slip automatic rotary socks / gloves silicon printing machine

Application:

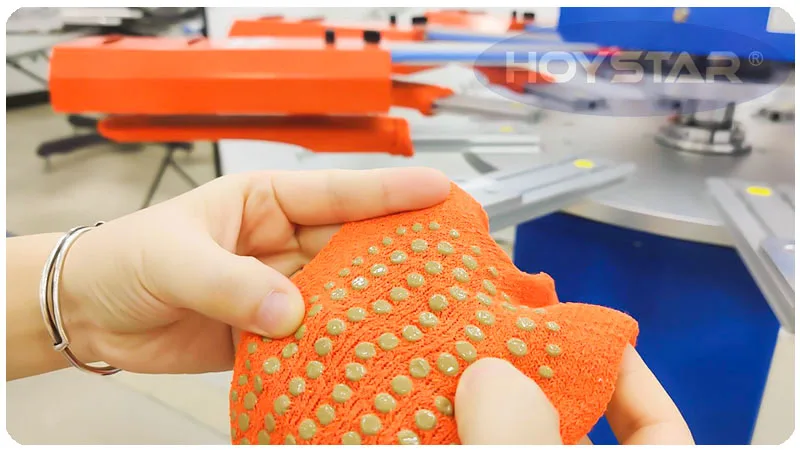

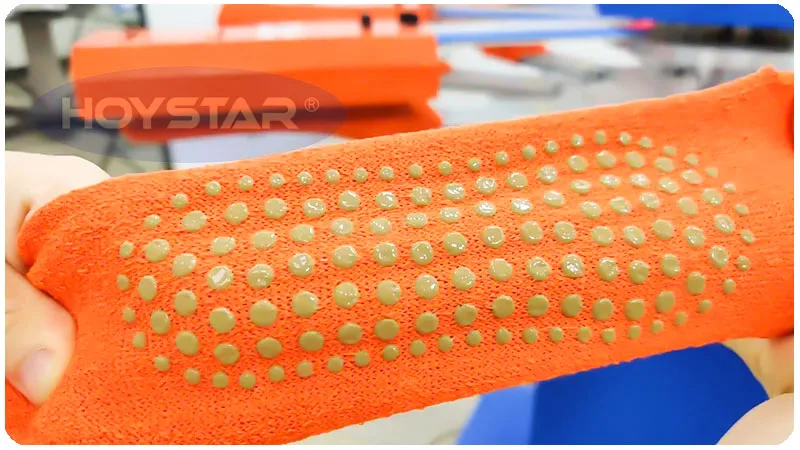

high rapid sock screen printer in textile knitting industry,the speed can be up to 1000PCS/Hr,it is suitable for printing garment tagless,sock or label,

rotary wortable,very convenient to load or unload products,lots of customers like it very much because of high quality and low price

Audited supplier

Audited supplierFunction:

1) PLC controlled,user friendly interface,clear function display and easy operation.

2) Flat screen printing with infrared drying system.Suitable for different types of ink and small area screen frame printing

such as socks,gloves,tagless, T-shirt collar,bags.

3) Ten station driven by step motor to insure stable and smooth running.

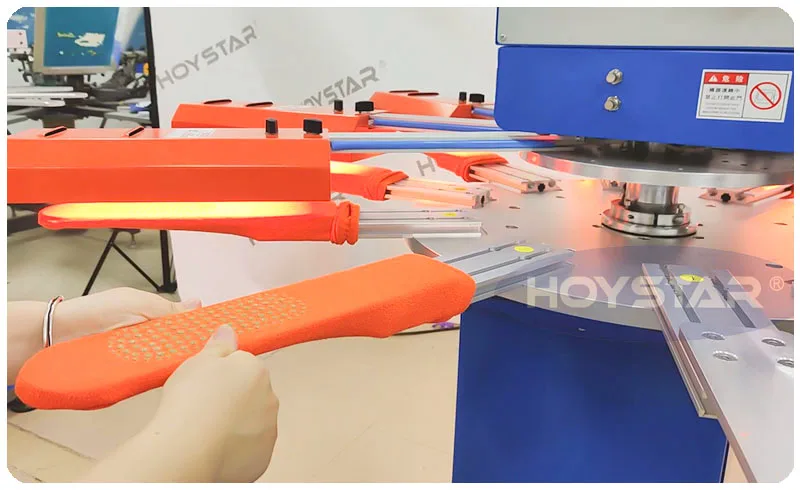

4) Angle and height of squeegee and flood blade can be adjusted to insure consistent printing pressure.

5) Adopts 10 stations rotary worktable,one for substrate loading and one for printing,6 workstation for drying and one for

substrate unloading and five stations working simultaneously.

6) With one cycle and auto function and switch easy.

socks,gloves,garment,tagless,or label,rotary workable,very convenient to load or unload products,lots of customers like it very much because of high quality and low price.

Technical parameters | ||||

1) Max.printing area | 100*250mm | |||

2) Worktable size | 110*300mm | |||

3) Workstaion | 10 pcs | |||

4) Drying system | 6 pcs | |||

5) Power | 6 KW | |||

6) Machine size | 16500*13500*1600mm | |||

7) Weight | 260kg | |||

2) Flat screen printing with infrared drying system.Suitable for different types of ink and small area screen frame printing such as socks,gloves,tagless, T-shirt collar,bags.

3) Ten station driven by step motor to insure stable and smooth running.

4) Angle and height of squeegee and flood blade can be adjusted to insure consistent printing pressure.

5) Adopts 10 stations rotary worktable,one for substrate loading and one for printing,6 workstation for drying and one for substrate unloading and five stations working simultaneously.

6) With one cycle and auto function and switch easy.

Audited supplier

Audited supplier

Full Automatic 2 Color Cylindrical Screen Printing Machine for Oil Filter

Automatic Screen Printing Machine for MDF blackboard/Plastic Chalkboard

Professional Balloon Screen Printing Machine With Rotary Worktable Manufacturers

Fully Automatic 1 Color Pad Printing Machine for Plastic Hanger Size Markers

Best 2 Color Automatic T Shirt Screen Printing Machine Supplier

Best 3 Color Pad Printing Machine for Round Plastic Cover/Container Cover Factory Price - Hoystar Printing

3/4 Automatic Screen Printing Machine with Auto Unloading System For PVC/PCB/Paper

Full Automatic Cutting Mat Printing /Blackboard Automatic Screen Printing Machine with IR drying

Fully Automatic Pad Printing Machine for ruler / scale Printing