Hot embossing print PMMA/MS LGP for 55inch TV LCD BLU

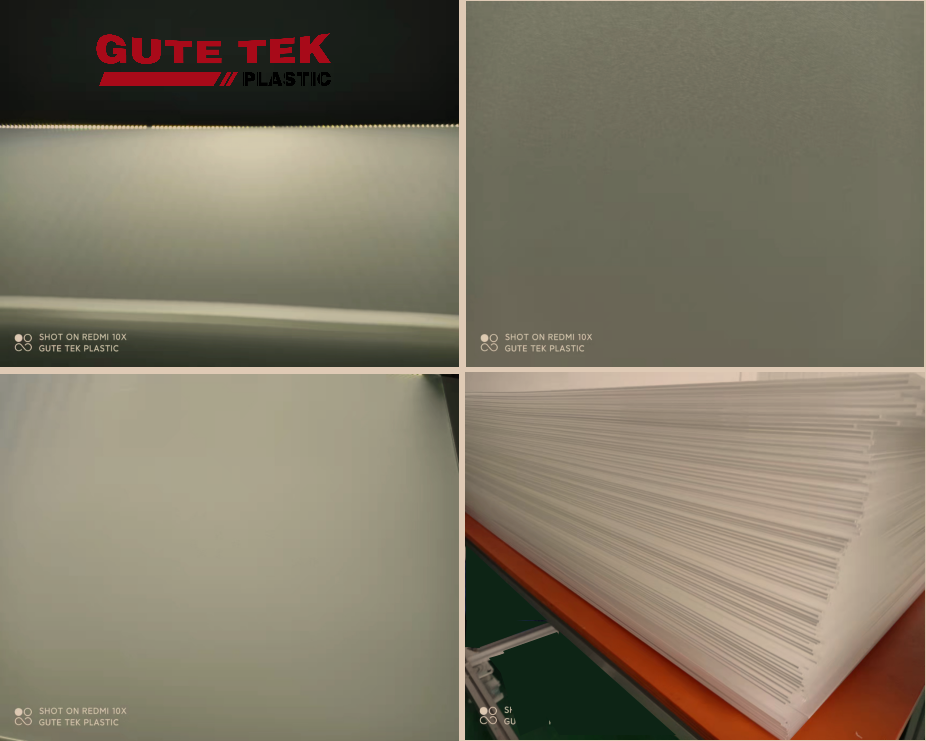

Hot pressing print technology was first applied to the production of notebook light guide plates, mass production in South Korea around 2012, and then introduced to mainland China, and now become one of the dominant technologies for the production of medium and large size light guide plates such as monitors, notebook computers, and LCD TVs. After continuous improvement and improvement, now this technology can process with various sizes, and has the advantages of high production efficiency and high rate of qualified products.

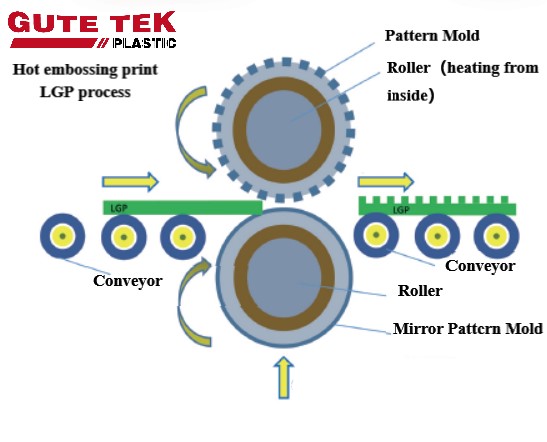

The principle of hot embossing print is the processing of dots is done by using the physical properties of plastic deformation of PMMA/MS/PC LGP materials when heated.

Audited supplier

Audited supplier

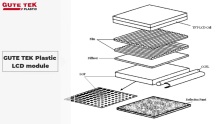

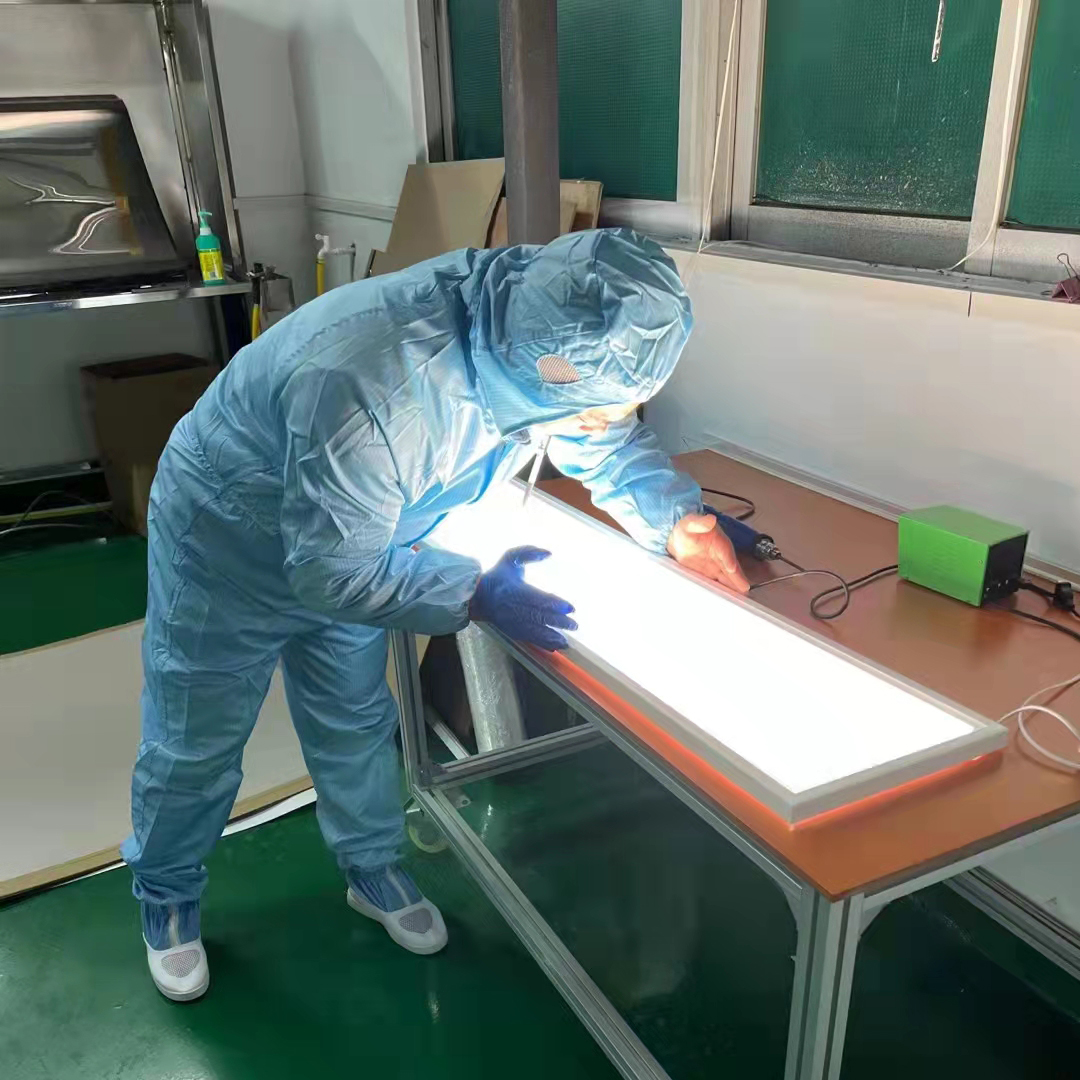

With the rapid update of desktop displays, laptops and other electronic products, usually 1-2 years will be updated once, ultra-thin, narrow boarder, high dynamic display, low energy consumption, high color saturation and size larger which has become a trend;Light guide plate as one of the key components of the backlight module, its structure and performance has tremendous influence on the backlight module and liquid crystal display effect;Customization has also become a trend of the LGP, the processing and production technology requirements of light guide plate are also higher; When purchasing light guide plates, customers will comprehensively consider various factors such as R&D capabilities, process technology, product quality, supply stability, response speed and product quotation of light guide plate suppliers. GUTE TEK PLASTIC not only has a professional R & D team, but also has an independent light guide plate processing workshop, equipped with cutting lathes and laser dotting workshops and hot embossing print light guide plate processing workshops, to provide customers with efficient customized services.

Once the TV set is large size and ultra-thinning, then the requirements of the light guide plate is higher, the light guide plate laser dotting process takes a long time, which has higher requirements for laser energy stability and mechanical operation accuracy, so the production efficiency is difficult to improve; hot embossing print technology no need to worry about this problem, and now the hot embossing print technology is mainly used in televisions, notebooks, displays, LED lamps acrylic PMMA or MS light guide plate(LGP) processing;

For various sizes of televisions, laptop and displays and other products, the size requirements of the hot embossing mold are not the same, and the size of the light guide plate processed is also different, such as:

7-15.6 inch notebook computer, the minimum PMMA/MS light guide plate(LGP) size that can be processed is 150*85mm, the maximum size is 350*195mm, and the thickness is between 0.5-1.0mm. Taking a 15.6 inch notebook computer as an example, the production capacity of a hot embossing printer can be 5650pcs a day;

The 18-32 inch display, the minimum acrylic and MS light guide plate size that can be processed is 400*230mm, the maximum size is 720*400mm, and the LGP thickness is between 1.0-3.0mm. Taking a 32inch display as an example, one machine could make 3450pcs;

The 42-65-inch TV, the minimum LGP size that can be processed is 950*520mm, the maximum size is 1450*850mm, and the thickness is between 1.0-3.0mm. Take a 65-inch TV set as an example, the daily production capacity is 2650pcs;

There are also LED 600*600mm LED Edgelite Slim panel lights, the minimum light guide plate size that can be processed is 450*360mm, the maximum size is 700*700mm, and the thickness is between 1.0-4.0mm. The daily production capacity is 3050pcs;

1200*600mm LED side lighting panel lamp, the minimum LGP size that can be processed is 550*550mm, the maximum size is 1350*700mm, and the thickness is between 1.0-4.0mm. And the daily production capacity of 2650pcs;

Audited supplier

Audited supplier

Hot embossing print PMMA/MS LGP for 55inch TV LCD BLU

GUTE TEK Plastic- how to determine polarizer sheet degree

Reflective film of backlight units for LCD module from GUTE TEK PLASTIC

GUTE TEK Plastic ultra thin light guide plate(LGP)for laptop display

Reflective film of backlight units for LCD module from GUTE TEK PLASTIC

Reflective film of backlight units for LCD module from GUTE TEK PLASTIC

GUTE TEK Plastic 0.125mm thickness light diffuser film for laptop display

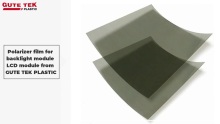

Polarizer film for backlight module LCD module from GUTE TEK PLASTIC

What is the difference between the traditional diffuser film and the LCD diffuser film?