MGG group is a professional cryogenic vials manufacturer in China, in the production process of cryogenic vials, all environmentally friendly medical materials are used to ensure the quality of the products. After the production of the product is completed, our quality inspectors will conduct quality inspections on the product, and the products without problems will be packed in boxes.

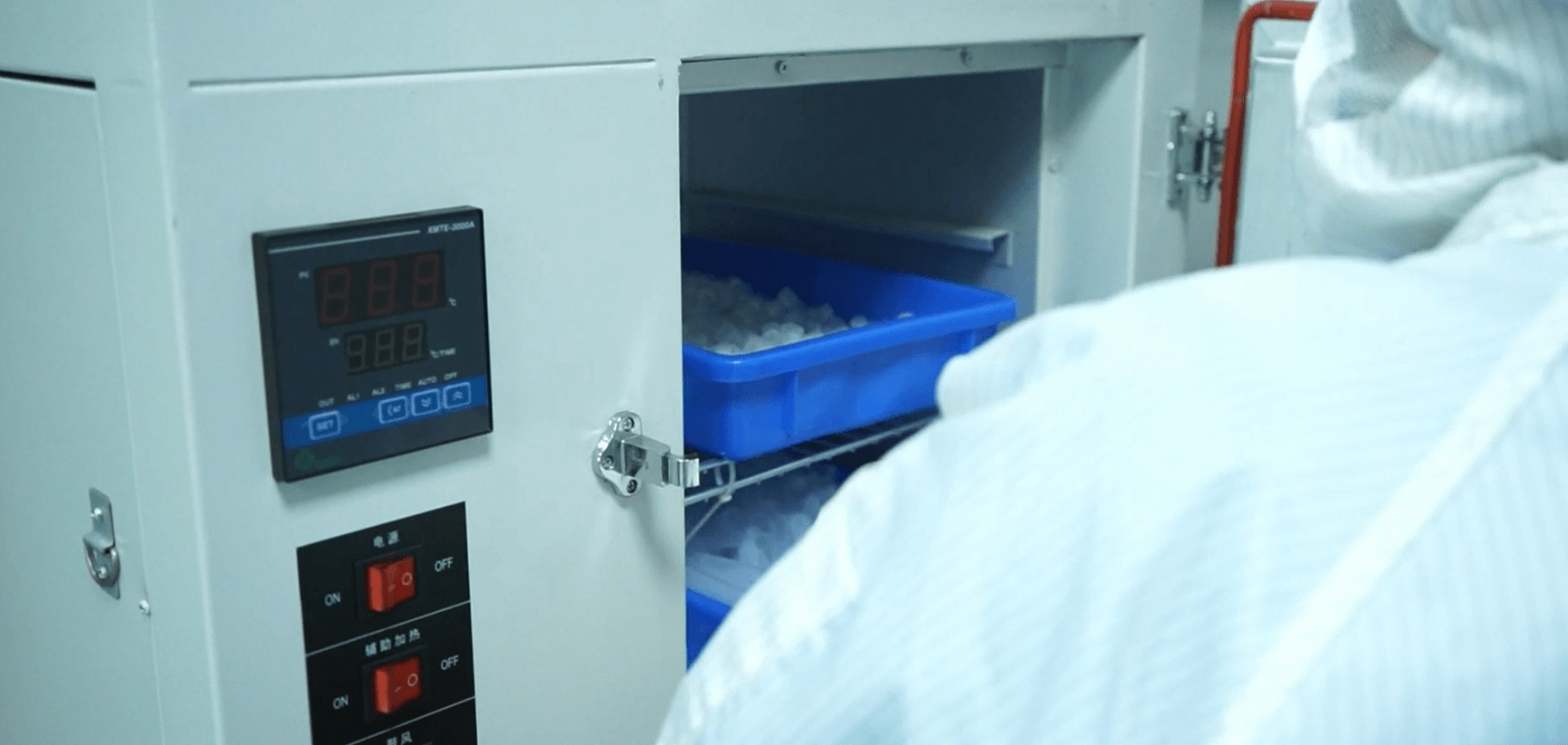

For each batch of products, part of the freezing tubes will be selected for high temperature resistance testing and placed in a machine with a high temperature of 60 degrees for 24 hours to observe changes. Discoloration is not brittle.

MGG group conducts high-temperature testing on cryogenic vials to ensure the quality of products and reassure customers that MGG group is your trusted supplier.

FAQ

1.Do you supply free sample ?

Yes. We are very glad to provide you free sample before formal order. To get free samples by clicking below send and sent us your inquiry.

2.Are you a manufacturer or a trading company?

We are a manufacturer with more than 15 years OEM experience in pharmaceutical ,cosmetics and personal care products packaging.

3.Can I custom my own logo and custom the bottle color ?

Yes. We can custom your logo on product, and custom the color as your desire. Just sent us your artwork and PANTONE code.

Advantages

1.The machines are fully automatic robots, high precision, fast speed, large capacity.

2.15 years OEM experience.

3.Professional R & D teams provide free 3D design,free 3D printing.

4.100,000-class dust-free workshop and passed ISO9001:2015 quality management certification and GMP auditing.

About MGG

Shenzhen Jinlongxin Plastic Co., Ltd established in 2006, it developed into a group(Meiguo International Group Co., Ltd)(Hereinafter referred to as MGG), which has jurisdiction over Jinlongxin Plastic(H.K.) Co., Ltd, Dongguan Meiguo Plastic Co., Ltd, and Huizhou Jinlongxin Plastic Packing Co.Ltd.

MGG is specialized in manufacturing and exporting different kinds of plastic packing container which are mainly used for pharmaceutical ,cosmetics and personal care products industrial, our company have 15 years OEM experience and passed ISO9001:2015 quality management certification and GMP auditing, all products are food and medical grade and all processes are produced in a modern, fully enclosed, 100000 grade dust-free workshop.This is especially important when the epidemic is still severe, and the machines are fully automatic robots, high precision, fast speed, large capacity and we have good market in United states, European, Canada,Mexico, Asia, etc .

Crystal appointed MGG, a personal care plastic bottle supply company, to be their roll on deodorant bottles supplier.

Most anti-perspirant deodorant was a roll-on form plastic bottle made of four components -cap, ball, bottle and the ball base. MGG team re-designed and made it a three components roll on plastic bottle. And passed the vacuum test without leakage , so easy to travel to carry .Crystal was pleased with our work and the orders has been going on for five years.The reducing of component amount means cost-saving, labor reduction and product improving, which is what every company wants.

Crystal's bottles have 8 different surfaces. It is a challenge to cover a single sticker on the 8 surfaces of the bottles. This is one of the few manufacturers that can do it,Our company is one of them. MGG provides labelling services for strange shaped bottles.

Colgate hello and Crystal have also commissioned MGG to develop and produce their deodorant stick container. Our fully enclosed injection molding workshop uses fully automatic machines with a daily capacity of 200,000 units.

MGG professional R & D teams can complete the difficult OEM requirements and provide value-added packaging services for your products. And provide free 3D design, free 3D printing .

MGG's own large mold room can provide free product testing mold, provide packaging containers for customers' new product testing market.

Audited supplier

Audited supplier

Audited supplier

Audited supplier