Gas Electric Rotary Roller Kiln for Ceramic Brick Tile

Roller kiln, also known as roller bottom kiln, is mainly used for the production of ceramic building materials. It is a long-term firing kiln, and a tunnel kiln with twisted rollers as a carrier for the green body.

Audited supplier

Audited supplier1.1 This electrical heating roller kiln project is designed by our professional technical designer team, which combined national conditions and roller kiln characteristic from domestic and abroad, optimized design to produce high quality, high efficiency and energy saving roller kiln. With the advantage of large output, stable quality, low energy consumption, easily operation and others, it is ideal firing equipment.

1.2 Kiln adopts modulization design and field assembling method, to ensure the precision of manufacturing, meanwhile to shorten installation time. Kiln firing use gas fire flame direct fire heat products, to improve products quality and level, reduce energy consumption and save more energy.

1.3 This kiln adopts excellent refractory thermal insulation materials, use mullite light-weight refractory brick as liner in

firing zone. Thermal insulation materials use high quality insulates plate and light-weight insulates felt greatly reduce the heat dissipation of kiln.

1.4 This kiln use automatic and manual control according to requirement of actual work, while ensuring to reach technical

requirements at the same time, it can greatly save investment. The kiln driving use 45 degree helical gear driving by cycloid reducer, transducer control driving speed, it is easy to control firing cycle to meet the demand of firing requirement of different products. It has advantage of easy operation, convenient, stable and reliable driving and others.

Audited supplier

Audited supplier

VP75 Vacuum Clay Brick Production Line With Tunnel Kiln

Shuttle Kiln

JKR18 Small Vacuum Clay Brick Tile Extruder Machine

Clay brick packing machine for rotary kiln

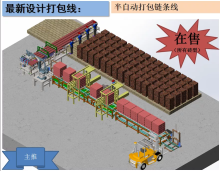

Semi auto clay brick packing machine with stacker

Gas Electric Rotary Roller Kiln for Ceramic Brick Tile

Full Auto Semi-Auto Clay Cement Brick Block Packing Machine

Fully Automatic Mud Vacuum Extruder Hollow Red Clay Brick Making Machinery

Clay Wire Cut Brick Making Machine