Factory Pictures

Shandong YULONG Machine Co,Ltd. is a integrated enterprise with product development ,design,manufacturing,training,and trade.

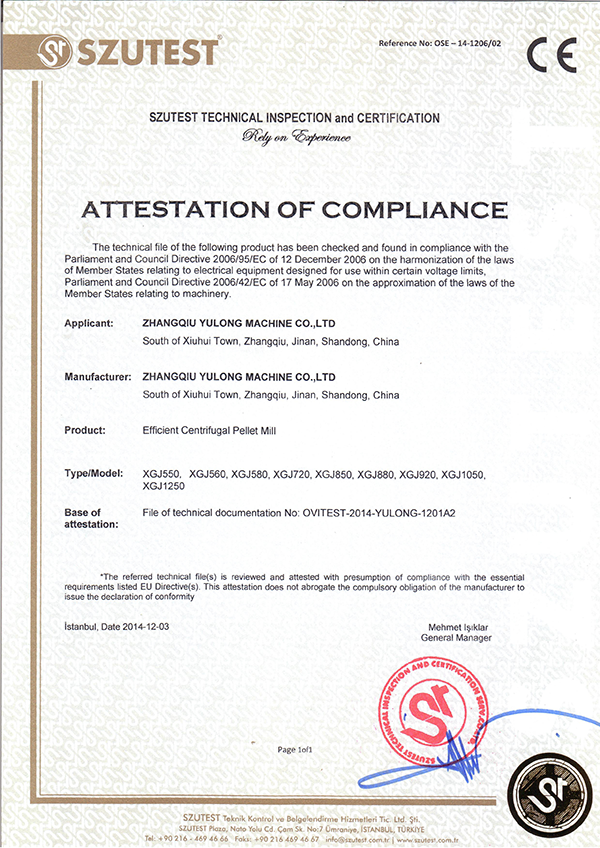

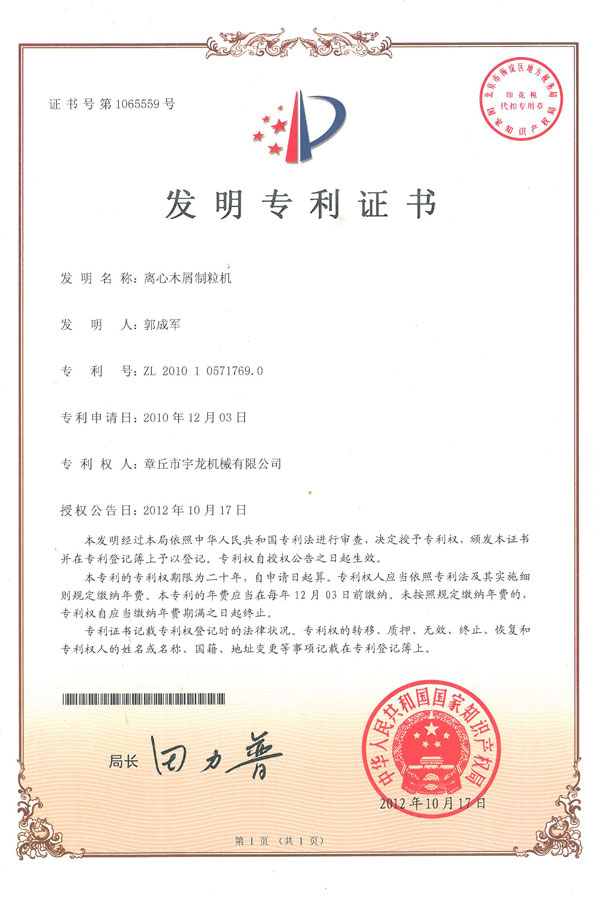

YULONG was founded in August 1988.YULONG has 32 patents on its own R&D products, has passed the ISO9001 quality management system certification, EU CE ,SGS certification and so on,and has been appraised as “high-tech enterprise”,”Shandong province famous trademark”,”shandong province specialized and special enterprise”,”china`s top 100 science and technology innovation small and medium-sized enterprise”,”city level science and technology progress award third prized”,”industrial economy top 100 enterprises”,” third prize of municipal science and technology progress award” and other honorary titles.YULONG has modern R&D facilities and information equipment to facilitate business communication with customers around the world,and create good information conditions for the company`s product exportation.

As a leader of the biomass pelletizing equipment industry, YULONG is committed to creating maximum value for our customers.Our company supports on stop service for biomass pelleting equipment and services. We have first-rate design ability ,first-rate product supply ability, first-rate installation service,first-rate product quality control standards,first-rate program comparison optimization ability and first-rate customer service consciousness.

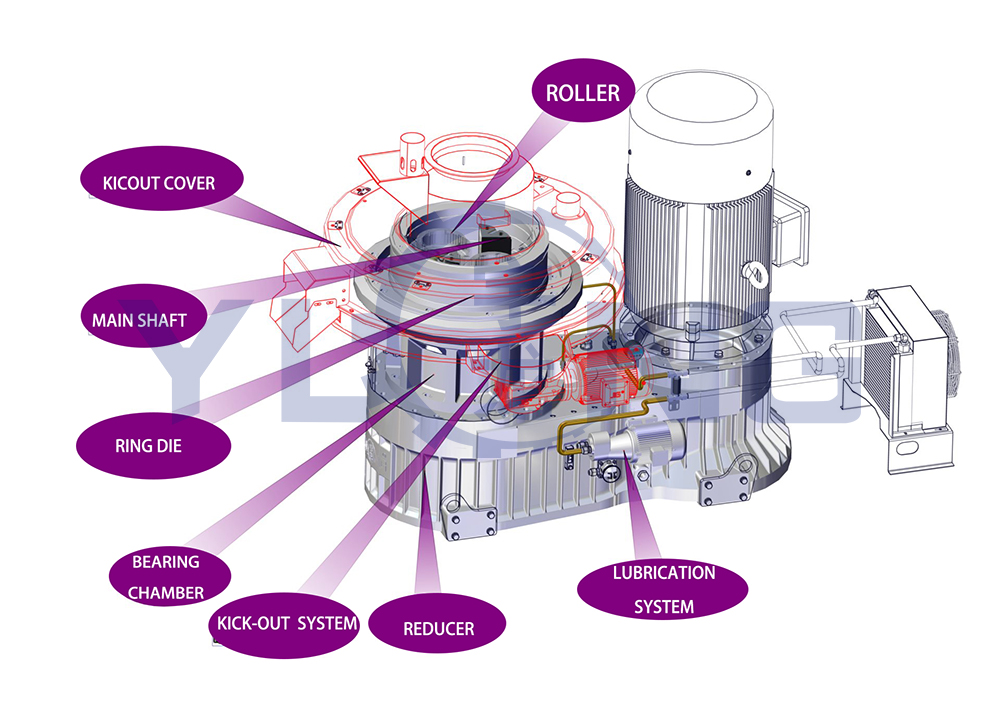

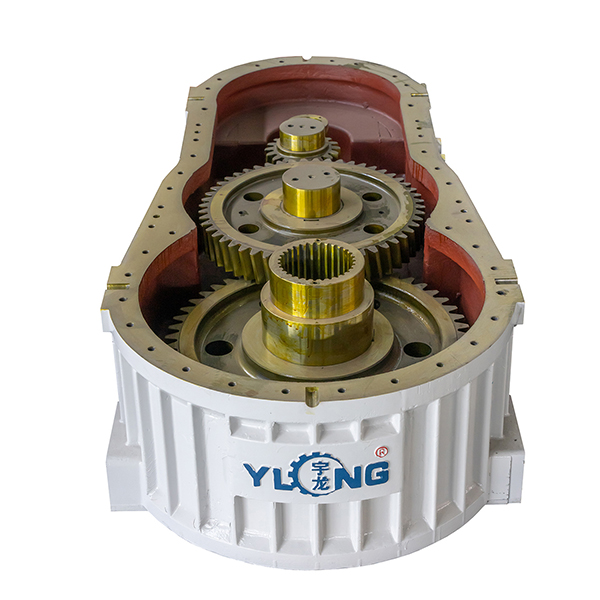

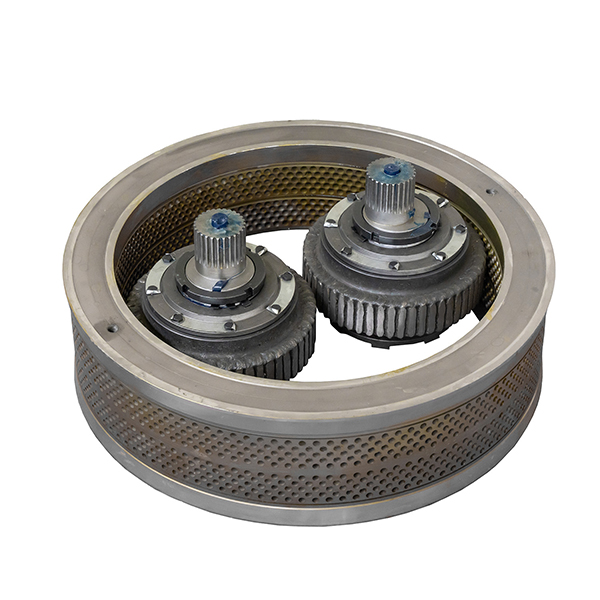

Our company has not only researched three series of pellet mill, briquette press, crushers, hammer mill, mixer, cooler and pasture machinery but also the complete sets of feed, forest, fertilize, energy machinery equipments with more than ten kinds of high-quality products. They have been exported to Southeast Asian, Europe, Africa, and America, and so on.

FAQ

Voltage requirement?

Our machines can use 380V, 220V, 240V, 415V, 480V, and 50Hz, 60Hz.

Will you send engineers to install the machines?

Of course. Our company has professional installation engineers team and specialized after-sale service team. When the machinesarrive your factory, we will send our installation engineers to your factory Our engineers will Guide you to install the machinesand training your workers how to operate the machines and maintain the machine.

How long is your guarantee?

12 months warranty but except quick waering parts.

General questions to design the production line for you?

1. What is your raw materials? (to confirm mould pressure ratio of machines ) 2. What is the moisture content of your raw material?3. How many output capacity do you want per hour / month/ year? Note: If the moisture is high, you need a dryer, becuase the suitable moisture content to enter pellet machine is 13-15%. Andplease provide us above detailed information, then we would design the most suitable production line with reasonble offers.

Our services

The capacity is customized for your needs, 1-1.5 tons, 2.5-3.5 tons, more than 5 tons.

Provide biomass pellet plant design, installation and cost accounting.

Will be available online almot in 24 hours service for your esteemed company.

We are glad to hear from you soon and to start a business relationship with your esteem company.

![How to Assemble Pellet Machine / Pellet Machine Installation - Detailed Guide [2022]](https://img001.video2b.com/995/file_01650013905751.jpg?x-oss-process=image/resize,m_lfit,w_220)