Gravity Casting Wheels - Iconic Styling & Quality Supplier & Manufacturers | JWHEEL

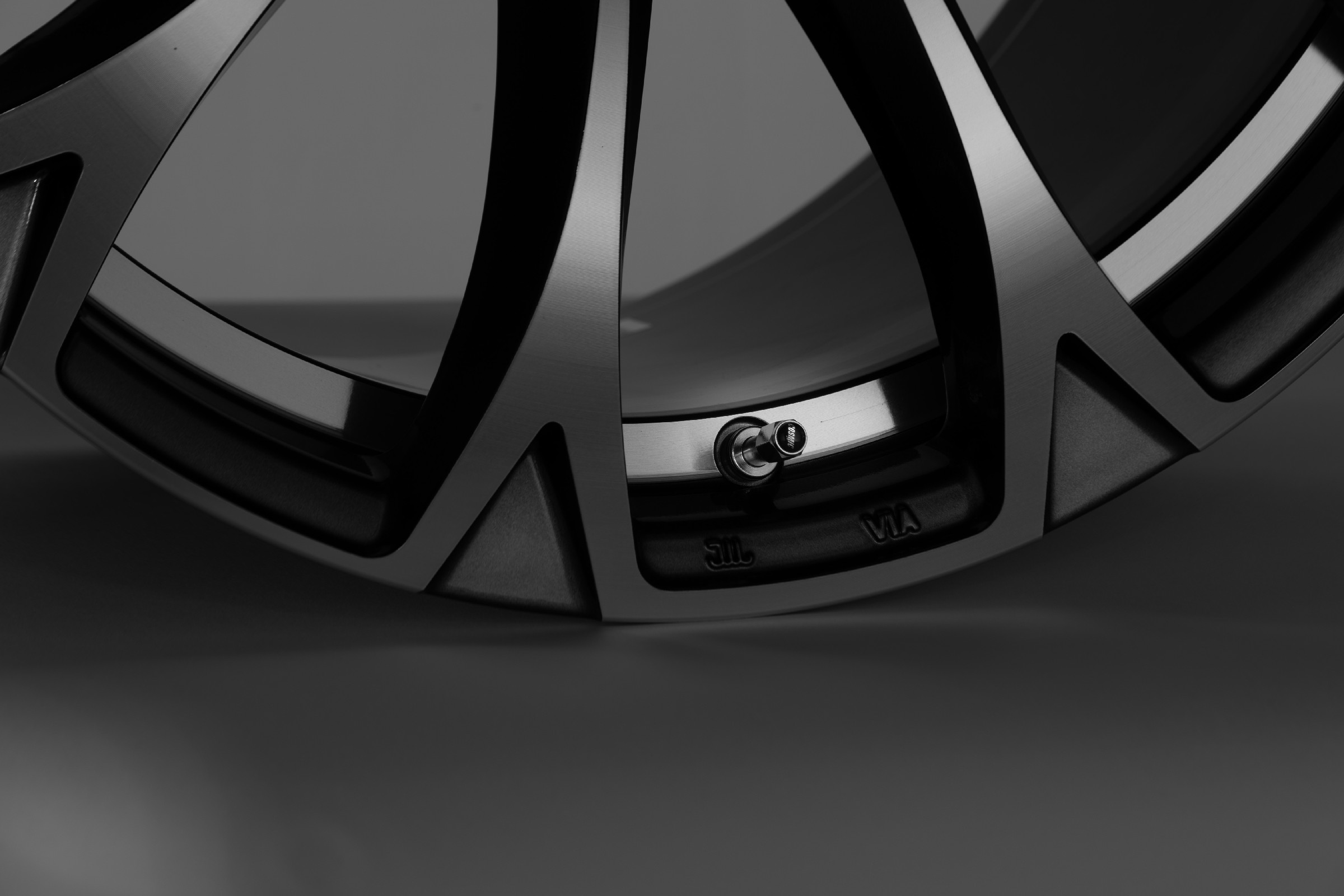

Gravity casting is the most basic process of pouring molten aluminum into a mold utilizing the earth's gravity to fill the mold. Gravity casting offers a very reasonable production cost and is a good method for casting designs that are more visually oriented or when reducing weight is not a primary concern. Since the process relies on gravity to fill the mold, the aluminum is not as densely packed in the mold as some other casting processes. Often gravity cast wheels will have a higher weight to achieve the required strength.

Audited supplier

Audited supplier

FAQ

Advantages

A forged wheel is manufactured from a billet, or a large square piece of solid metal. ... The manufacturing process results in a stronger wheel by eliminating cavities, porosity, and shrinkage. Due to its tighter grain structure, forged wheels are also mechanically stronger, ensuring better wear resistance over time.

Forged rims are made from solid aluminium that are heated to allow pressurized machines to shape the rims. Forged rims gets its name from the process of forging a single piece of aluminium into the shape of the wheel rims. Cast wheels on the other hand are made from aluminium that is melted into the liquid form, and poured into molds.

There are significant advantages to forged wheels such as forged wheels being 3x stronger and 25% lighter which is everything you want in a dedicated race car. The down side is that it costs 3x as much than a cast wheel.

About JWHEEL

Audited supplier

Audited supplier

Intro to Customized Aftermarket Aluminum Wheel JWHEEL

Gravity Casting Wheels - Iconic Styling & Quality Supplier & Manufacturers | JWHEEL

China OEM/ODM Casting Service Supplier JWHEEL for Car Wheel Manufacturers

Wholesale High Quality Porsche Racing Wheels Factory with Best Price - JWHEEL

Customized Alloy Wheels For 2022 New design manufacturers From China | JWHEEL

Professional 2022 New Designs of Two types of Pressure Casting manufacturers Products | JWHEEL

High Quality Two-Piece Forged Car Wheel Rims 18 to 24 inch Supplier & Manufacturers | JWHEEL

Best Nice designs of alloy wheels M3,M4,M5.18~23 inch Always in Stock Factory Price - JWHEEL

Wholesale Customized 18 to 22 inch Aluminum Alloy Gravity Casting Car Wheels Rim Manufactures-JWHEEL