OEM Zinc Alloy Die Casting Machine Parts

In recent years, zinc alloy die castings have been widely used, and the technical level of the zinc alloy die casting industry has also been greatly improved. So, what are the advantages of using zinc alloy die castings?

1. The products produced by zinc alloy die castings are relatively much larger, and have a good sense of layering and net weight. The compressive strength of zinc alloy die castings is also much larger than that of plastic injection molding.

2. The surface of the product produced by zinc alloy die casting is very smooth and not rough.

3. The die casted by zinc alloy can carry out surface production and processing, and can carry out electroplating process, spraying and other production and processing on the surface.

4. Zinc alloy die-casting is used to manufacture molds, its productivity is very high, and the number of times the molds can be used can reach tens of thousands of times.

5. Zinc alloy die castings have excellent production results. The products produced by zinc alloy die castings have very good physical properties at room temperature. In addition, they also have very good wear resistance. Not easy to damage.

6. Another key point is that the price of molds produced by zinc alloy die castings is much lower than that of molds produced by traditional handicrafts, which greatly saves product costs. This is the point that every customer pays the most attention to.

Audited supplier

Audited supplierOur Service

1) OEM、Die Casting、CNC Machining、Surface Treatment

2) Own mould R&D team and mould making workshop.

3) Own factory to offer the reasonable prices and quick response.

4) One-to-One after sales services,answer question for customers 24 hours every day

5) Experienced project team,each product is tracked by a specially assigned person

| Product application field | Beauty and medical, consumer electronics, smart home, automotive, robotics, communications,luggage and other industries |

| Equipment | Zinc alloy die casting machine, aluminum alloy die casting machine, CNC equipment, ultrasonic equipment, polishing machine, grinding machine, automatic tapping machine, etc. |

| Material | Zinc alloy: #2, #3, #5 Aluminum alloy: ADC12, A380, ADC10 |

| Surface Technology | Electroplating, baking paint, powder spraying, sandblasting, electrophoresis, silk screen, wire drawing, laser carving, etc. |

| Surface treatment | Trimming, deburring, deburring, drilling and tapping, polishing, CNC machining |

| Product testing | PCA test, white chrome test, alcohol test, eraser test, salt spray test, hardness test |

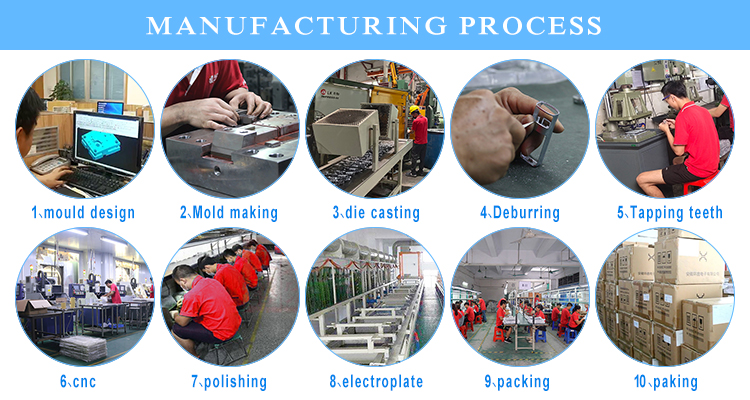

| Production diagram | Drawings or samples → making molds → making samples → casting → deburring → deburring → drilling and tapping → polishing → CNC→Surface treatment (electroplating, baking paint, sandblasting, powder spraying, or according to customer requirements) →Printing Logo→Quality inspection→Packing→Delivery |

Our advantage

1.16 years of experience in customizing zinc aluminum alloy die castings.

2. 10 die-casting machines produce 24 hours a day, with a daily output of 20W pieces.

3. Set up an independent mold room, with a mold making department and various sophisticated mold manufacturing equipment.

4. Won the ISO9001-2015 quality system and RoHS certification.

5. Have its own surface treatment department, one-stop production from product mold design to product shipment.

6. The drawings are kept confidential for life, signed a confidentiality agreement, and a sound confidentiality system.

Company Profile

Shenzhen Huayin Precision Products Co., Ltd. has focused on the die-casting industry for 16 years. With a plant area of 5,000 square meters, Huayin has a team of more than 200 people. The company specializes in mold design, mold production, zinc-aluminum alloy die-casting, CNC machining, stamping and injection molding.

Our product application areas include: beauty and medical, electronics, smart home, automobiles, robots, communications, luggage and other industries. We can meet any complex requirements of customers in the shortest time. To provide customers with the best manufacturing solutions and quality service is our aim.

Huayin is equipped with a brand new die-casting machine, enabled intelligent automated production, and equipped with the necessary testing instruments in the die-casting industry. During the production process, we have professional project engineers to follow up your products throughout the process, with guaranteed quality and production speed quick.

We sincerely look forward to establishing a happy cooperation with you!

Packaging & Shipping

Payment:

Standard payment terms:30%deposit in advance,70% balance before shipment

Online trade assurance order.

More payment terms(T/T,Paypal)

Shipping:

Port:Shenzhen

Time:10-20 working days after payment receipt confirmed

Packing: according to customer's demand ( with pearl-cotton package.)

professional goods shipping forwarder

FAQ

Q1. Are you a factory or trade company?

We are a factory with over 16 years in die casting. We service customers zinc alloy ,aluminum alloy die casting,CNC machining,packing,and surface treatment.

Q2.What kind of production services do you provide?

Mold opening ,Die-casting ,CNC machining and Surface treatment.

Q3. How long should we take for a quotation?

After receiving detailed information(your 3D drawings or samples), we will quote you within 2 days.

Q4.What materials can your company do?

Our company can make both zinc alloy and aluminum alloy. Which material do you want to make?

Q5.What is your quotation element?

Product structure, material, size, craftsmanship, weight, quality, order and other information

Q6.How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment.

If you have any questions, please to contact us !

Audited supplier

Audited supplier

Customized Precision Gravity Die Casting Zinc Alloy Parts

Zinc alloy die-casting beauty instrument accessories

Zinc Alloy Die Casting Parts Manufacturers - Huayin

Aluminum Die Casting Parts Supplier & manufacturers | Huayin

Custom Zinc Die Casting Parts Supplier & manufacturers | Huayin

China Zinc Alloy Die Casting Parts Manufacturers - Huayin

Precision Aluminium Die Casting Parts Supplier & manufacturers | Huayin

Custom Zinc Alloy Die Casting Products | Huayin

Intro to Zinc Alloy Die Casting Services for Customized Industrial Parts Huayin