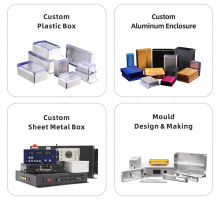

Knowledge points about aluminum enclosure | Shenzhen Hongfa Shunda Mould Co., Ltd.

Aluminum Enclosure Information

FAQ

Advantages

About Shenzhen Hongfa Shunda Mould Co., Ltd.

Aluminum alloys can be divided into two categories according to processing methods: deformed aluminum alloys and cast aluminum alloys.

Deformed aluminum alloys can withstand pressure processing. It can be processed into various forms and specifications of aluminum alloy. It is mainly used in the manufacture of aviation equipment, doors and windows for construction, etc. The deformed aluminum alloys are divided into non-heat treated strengthened aluminum alloys and heat treated strengthened aluminum alloys. The non-heat treatable strengthened type cannot improve mechanical properties through heat treatment, but can only be strengthened through cold working deformation, which mainly includes high purity aluminum, industrial high purity aluminum, industrial pure aluminum and rustproof aluminum. Heat-treatable reinforced aluminum alloy can improve mechanical properties through heat treatment such as quenching and aging, which can be divided into hard aluminum, forged aluminum, super hard aluminum and special aluminum alloy.

Cast aluminum alloys can be divided into aluminum-silicon alloys, aluminum-copper alloys, aluminum-magnesium alloys, aluminum-zinc alloys and aluminum-rare earth alloys according to their chemical composition, among which there are peri-eutectic silicon aluminum alloys, eutectic silicon aluminum alloys and single eutectic silicon aluminum alloys, and cast aluminum alloys are used in the cast state. Some aluminum alloys can be heat treated to obtain good mechanical properties, physical properties and corrosion resistance.

Plastic Enclosure ABS Control Box Network Case

Different steel sheets for Electronic Equipment Case

Wall-mounted enclosures

Best Quality Custom abs pc injection parts plastic electronic enclosure molds Factory

Aluminum factory supply extrusion housing for pcb

What are the basic requirements that need to be met when designing a sheet metal enclosure?

Printers made of sheet metal / Aluminum Case

About Shenzhen Hongfa Shunda Mould Co., Ltd. 17 inch LCD screen aluminum case

Extruded aluminum enclosure electronic Mini PC case