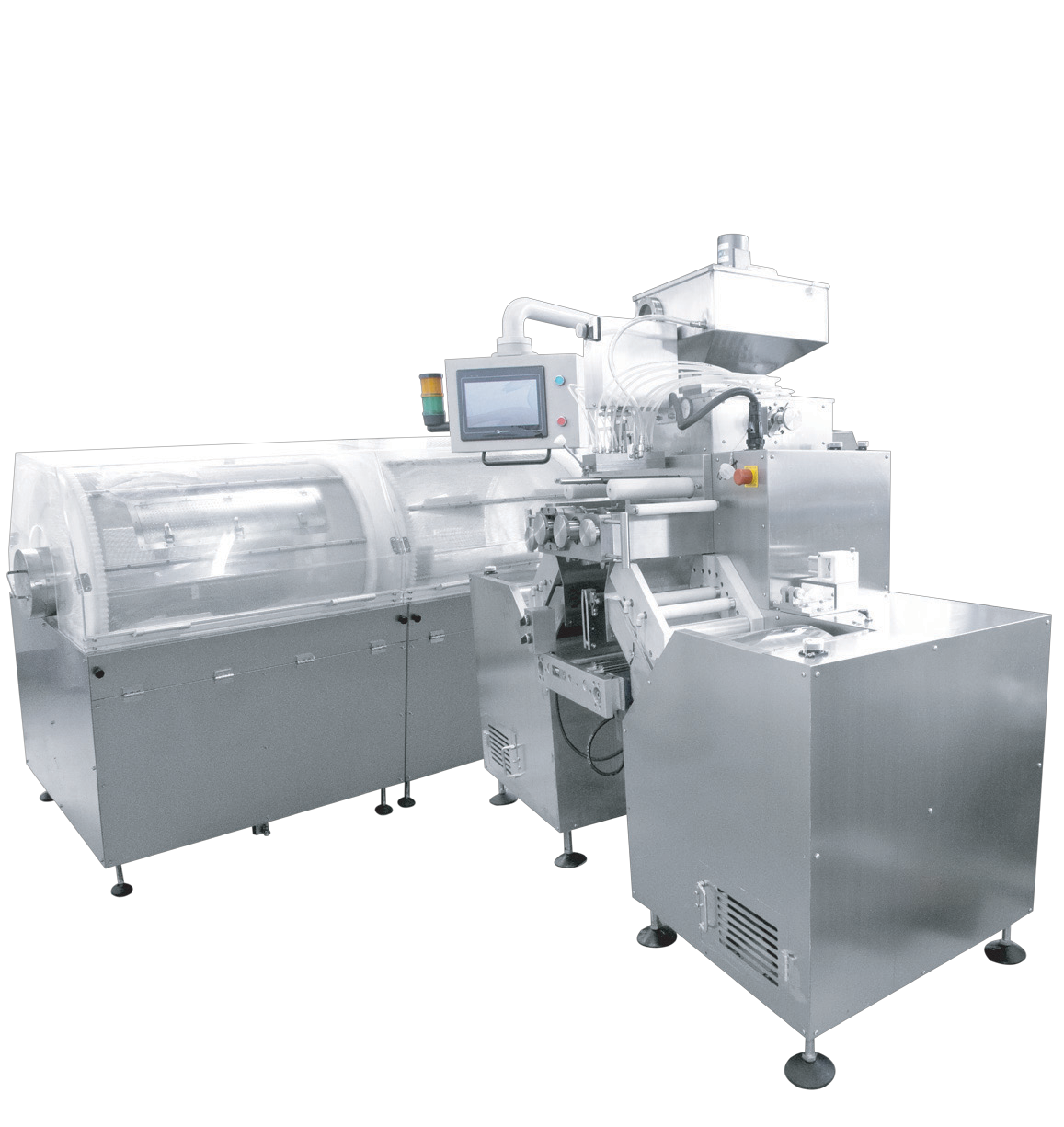

HSR Encapsulation Machine

This is your team section. It’s a great space to tell your story and to describe who you are and what you do. If you're a business, talk about how you started and tell the story of your professional journey. People want to know the real you, so don't be afraid to share personal anecdotes. Explain your core values and how you, your organization, or your business stand out from the crowd.

?New modular and standardized design:structure simple and stable, the spindle runs more stable.

?Main machine drive system:No liquid lubricant required.

?Materials supplying pump system:

Specially design for the extracts suspension sticky filling materials,wide range of applicable filling materials.

?Injection Wedge temperature control:Double PID control to ensure rapid response and precise control of injection wedge temperature.

?Gelatin film transmission:Full-range autonomous drive into the die roller,no sliding pull, no film deformation and perfect capsules shape.

?Gelatin film linear conveying, no need to adjust, production stable.

? Control type: Each system independent control, coordinated accordingly, easy to adjust.

?Die roller Pressure type: Pneumatic constant voltage, digital display, stable and convenient.

?Die roller adjustment: Free line aligning design, simplified operation to prevent operator’s error.

? Injection wedge lifting type: Electric self-locking, safe and reliable.

? Material supply pump: Free adjust design, easy install, prevent operator’s error,design of all rolling bearings to prolong service life.

?Material supply pump direction guidance: spherical guide (numerical control machine tool technology)