Zinc Die Casting Parts | Professional Production Die Casting Manufacturer

This is a zinc alloy die casting electronic product.Zinc die casting alloys have a wide range of excellent physical and mechanical properties, castability and finishing properties. Zinc alloys can be die cast into thinner parts than any commonly used die cast alloy. Due to the lower pressure and temperature of die-cast zinc alloys, the life of the die is significantly extended and the maintenance of the die is minimal.

Audited supplier

Audited supplierProduct Description

Zinc Die Casting Parts | Professional Production Die Casting Manufacturer

The material of this product is zinc alloy, and the product made of zinc alloy is heavier than the product of aluminum alloy, because the density of zinc alloy is heavier and the hardness is stronger. Advantages of zinc alloy: good fluidity, easy fusion welding, corrosion resistance; and strong plasticity, even the scrap can be recycled for remelting, and at the same time, it can die-cast precision parts with complex shapes and thin walls, and the surface of the castings is smooth. It can also carry out surface treatment such as electroplating, spraying, painting, polishing, grinding, etc., and has good mechanical properties and wear resistance at room temperature.

| Product application field | Beauty and medical, consumer electronics, smart home, automotive, robotics, communications, luggage and other industries |

| Equipment | Zinc alloy die casting machine, aluminum alloy die casting machine, CNC equipment, ultrasonic equipment, polishing machine, grinding machine, automatic tapping machine, etc. |

| Material | Zinc alloy: #2, #3, #5 Aluminum alloy: ADC12, A380, ADC10 |

| Surface Technology | Electroplating, baking paint, powder spraying, sandblasting, electrophoresis,silk screen, wire drawing, laser carving, etc. |

| Surface treatment | Trimming, deburring, deburring, drilling and tapping, polishing, CNC machining |

| Product testing | PCA test, white chrome test, alcohol test, eraser test, salt spray test, hardness test |

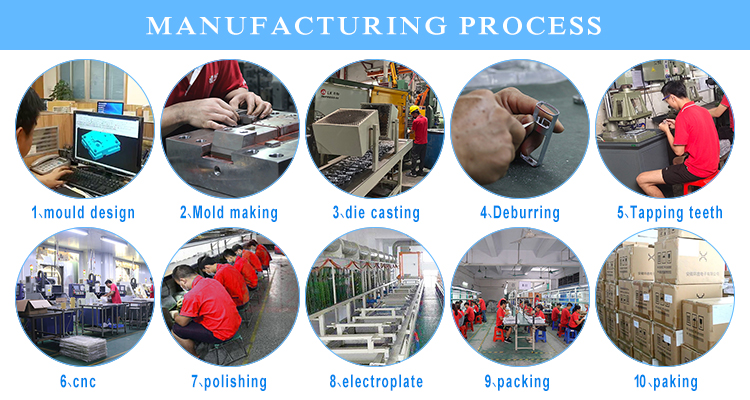

| Production diagram | Drawings or samples → making molds → making samples → casting → deburring → deburring →drilling and tapping → polishing → CNC→Surface treatment (electroplating, baking paint, sandblasting, powder spraying, or according to customer requirements) →Printing Logo→Quality inspection→Packing→Delivery |

Production process

Packing&Shipping

Payment:

Standard payment terms:30%deposit in advance,70% balance before shipment

Online trade assurance order.

More payment terms(T/T,Paypal)

Shipping:

Port:Shenzhen

Time:10-20 working days after payment receipt confirmed

Packing: according to customer's demand ( with pearl-cotton package.)

professional goods shipping forwarder

Our advantage

1. Strong production capacity, daily output is 200,000 pieces

10 die-casting machines produce 24 hours a day, with a daily output of 200,000 pieces

2. Set up an independent mold room, and the mold opening is 2-7 days faster than the peers

It has a mold making department and various precision mold making equipment, and has three mold designers with 20 years of experience. Mold opening is 2-7 days faster than peers

3. Qualification certificate

Won the ISO9001-2015 quality system Rohs certification

4. One-stop manufacturer

Set up an independent mold room, with its own surface treatment department, one-stop production from product mold design to product shipment

5. Drawings are kept confidential for life

Sign a confidentiality agreement, a sound confidentiality system, and three-level confidentiality of drawings and documents

6. Perfect quality control system

Huayin implements quality management: 5S quality management, production inspection, final inspection, quality control plan, incoming material inspection, production parts approval procedure, and employee periodic training. All staff participate in quality control.

Company Profile

Shenzhen Huayin Precision Products Co., Ltd. has focused on the die-casting industry for 16 years. With a plant area of 5,000 square meters, Huayin has a team of more than 200 people. The company specializes in mold design, mold production, zinc-aluminum alloy die-casting, CNC machining, stamping and injection molding.

Our product application areas include: beauty and medical, electronics, smart home, automobiles, robots, communications, luggage and other industries. We can meet any complex requirements of customers in the shortest time. To provide customers with the best manufacturing solutions and quality service is our aim.

Huayin is equipped with a brand new die-casting machine, enabled intelligent automated production, and equipped with the necessary testing instruments in the die-casting industry. During the production process, we have professional project engineers to follow up your products throughout the process, with guaranteed quality and production speed quick.

We sincerely look forward to establishing a happy cooperation with you!

FAQ

Q. Are you a factory or trade company?

We are a factory with over 16 years in die casting. We service customers zinc alloy 、aluminum alloy die casting、CNC machining、packing、and surface treatment.

Q. How to quote?

We will make the quotation when received the sample or 3D drawing,usually one or two days.

Q. How about your quality?

It passed ISO 9001 Certificate.Operation instruction will be made once the sample is approved.

Q. How about the lead time?

Mold: 3-5 days, Mass production: 30 days.

Q、What is your MOQ ?

We support a small number of sample orders to ensure your recognition of product quality, but the minimum monthly order quantity in the later period is at least 5,000 sets.

Q、Do you offer after-sales service?

We have a professional after-sales team, if you have any quality problems after receiving the product, you can contact us at any time.

If you have any questions, please to contact us !

Audited supplier

Audited supplier

Customized Precision Gravity Die Casting Zinc Alloy Parts

Zinc alloy die-casting beauty instrument accessories

Zinc Alloy Die Casting Parts Manufacturers - Huayin

Aluminum Die Casting Parts Supplier & manufacturers | Huayin

Custom Zinc Die Casting Parts Supplier & manufacturers | Huayin

China Zinc Alloy Die Casting Parts Manufacturers - Huayin

Precision Aluminium Die Casting Parts Supplier & manufacturers | Huayin

Custom Zinc Alloy Die Casting Products | Huayin

Intro to Zinc Alloy Die Casting Services for Customized Industrial Parts Huayin