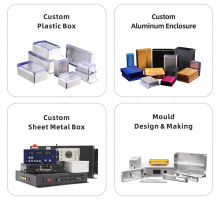

Die casting aluminum enclosure case junction box Control box

Casting is a process of metal smelting and processing, usually using the gravity of the metal to cast in a mold

Brief Introduction

Casting is a process of metal smelting and processing, usually using the gravity of the metal to cast in a mold. But "aluminum die casting" is not done by gravity, but by applying a certain pressure. It is somewhat similar to "injection molding". However, it has a more technical system of core extraction and cooling. In general, the material is delivered to the cavity to be cast through a centralized inlet to form the part.

Features

High pressure and high-speed filling of die-cast aluminum types are the two main characteristics of die-cast aluminum. It is commonly used pressure injection specific pressure is from thousands to tens of thousands of kPa, even up to 2×105 a. filling speed is about 10~50m/s, sometimes even up to 100m/s or more. The filling time is very short, generally in the range of 0.01~0.2s.

Advantages

1, good product quality: casting size accuracy is high, generally equivalent to 6 ~ 7, or even up to 4; the surface finish is good, generally equivalent to 5 ~ 8; strength and hardness is high, strength is generally 25 ~ 30% higher than sand casting, but elongation is reduced by about 70%; size stability, good interchangeability; can die-cast aluminum thin-walled complex castings. For example, the current zinc alloy die-casting aluminum parts minimum wall thickness of up to 0.3mm; aluminum alloy castings up to 0.5mm; minimum cast out hole diameter of 0.7mm; the minimum pitch of 0.75mm.

2, high production efficiency: high machine productivity, for example, domestic J Ⅲ3 type horizontal cold air die-casting aluminum machine can die-cast aluminum 600 ~ 700 times in eight hours on average, small hot chamber die-casting aluminum machine can die-cast aluminum 3000 ~ 7000 times every eight hours on average; die-casting aluminum type life is long, a pay die-casting aluminum type, die-casting aluminum bell alloy, life can reach hundreds of thousands of times, or even millions of times; easy to realize mechanization and automation.

3, the economic effect is excellent: because the die-casting aluminum size is accurate, the advantages of the table pan are glossy and clean. Generally, no longer mechanical processing and direct use, or processing volume are very small, so both improve the utilization rate of metal, but also reduce a large number of processing equipment and man-hours; castings are cheap; can use a combination of die-casting aluminum to other metal or non-metallic materials. Both save assembly time and save metal.

Disadvantages

1, die-casting aluminum because of the high speed of liquid metal filling cavity, the flow state is not stable, so the general die-casting aluminum method, the castings are prone to porosity, can not be heat treated.

2, for the concave complex castings, die-casting aluminum is more difficult

3, high melting point alloy (such as copper, ferrous metals), die-casting aluminum type life is low.

4, not suitable for small batch production, the main reason is the high cost of manufacturing die-casting aluminum type, die-casting aluminum machine production efficiency, small batch production is not economic.

Plastic Enclosure ABS Control Box Network Case

Different steel sheets for Electronic Equipment Case

Wall-mounted enclosures

Best Quality Custom abs pc injection parts plastic electronic enclosure molds Factory

Aluminum factory supply extrusion housing for pcb

What are the basic requirements that need to be met when designing a sheet metal enclosure?

Printers made of sheet metal / Aluminum Case

About Shenzhen Hongfa Shunda Mould Co., Ltd. 17 inch LCD screen aluminum case

Extruded aluminum enclosure electronic Mini PC case