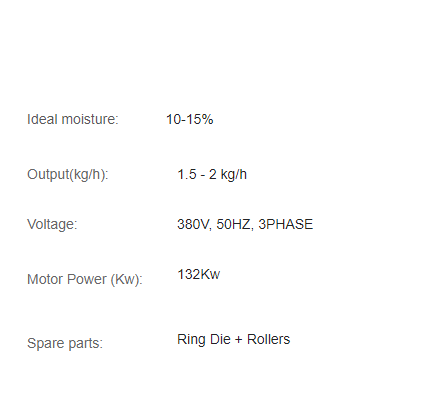

Wood Pellet Production Line Sawdust Pellet Mill Rice Husk Pellet Making Machine

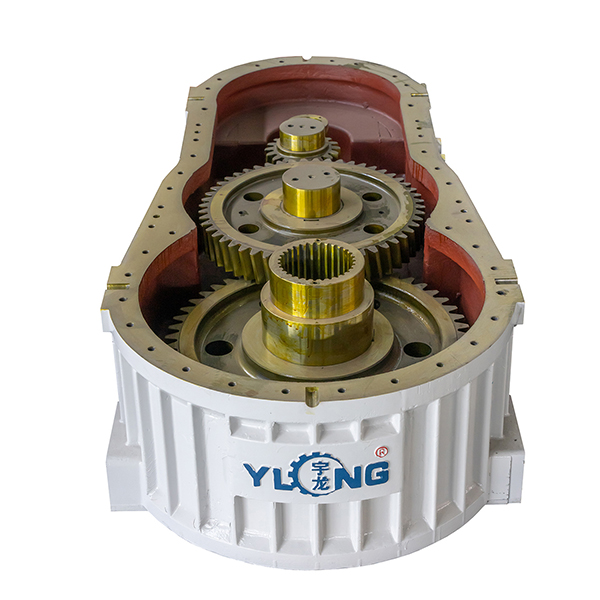

The centrifugal high-efficiency pellet machine originated from Yulong, and has undergone many core technology improvements and functional improvements since its development in 2010. Now updated to the eighth generation products.

Yulong has always mastered the patent and core technology of this product. The appearance of the product is easy to imitate by peers, but the core technology has never been surpassed.

The Main Advantages of the Eighth Generation Pellet Machine:

1. The main motor is changed to a standard flat key motor, and the German standard KTR elastic coupling is adopted with the reducer, which solves the problem of regular lubricating grease for the spline of the seventh generation granulator. Moreover, the replacement cost of KTR elastomer is much lower than the replacement cost after spline damage.

2. The positioning of the spindle frame plate and the spindle has been upgraded and improved, the pin positioning that is not easy to disassemble and easy to wear is removed, and the embedded positioning method of CNC machining is adopted, which is easy to disassemble and not easy to wear.

3. Improvement of kick-out system: The reducer of kick-out plate is replaced by a cycloidal pinwheel reducer to a hard-tooth surface reducer. The rotating components of the kick-out system are completely separated from the kick-out boot (the entire driving operation is outside), which completely solves the problem that the kick-out system is susceptible to high temperature steam. Moreover, in the kick-out boot of the pellet machine, except for the kick-out turntable, the rest of the non-moving parts that can contact the material and steam are all made of stainless steel, which fundamentally solves the corrosion problem of metal materials.

Audited supplier

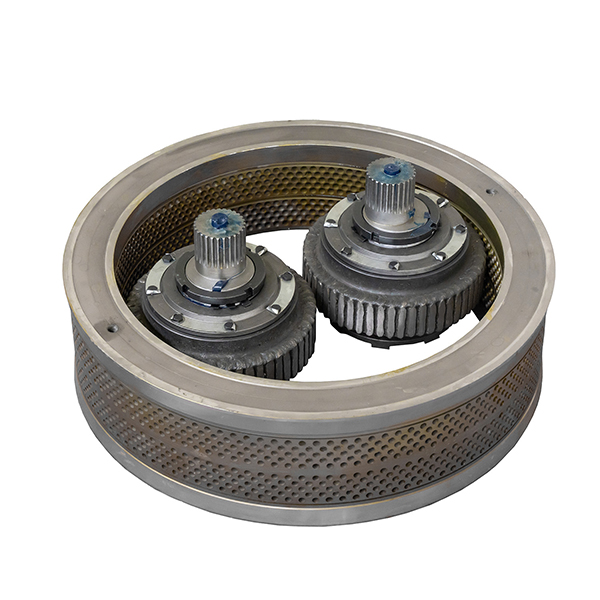

Audited supplierThe YULONG series vertical efficient centrifugal pellet mill incorporated the distinguishing features of all kinds of pellet mill at home and abroad. It has unique design, reasonable structure, lower energy consumption, higher efficiency, more stable in motion and much longer service life. It is a YULONG`S patent product which filled a gap of vertical pellet mill. It is wide applicability to the materials which is hard to molding and adhesive: ex. Palm fruit fibre and shell, rice husk, peanut shell, sunflower seed shell, agro-residues, timber processing residues, industial residues . XGJ series pellet mill has a variety of applications in feed plants, woodworking factories, biomass fuel plants, fertilizer plants, and chemical plant etc. It is an ideal dense compression molding equipment.

Audited supplier

Audited supplier

Making Fuel Pellets From Peanut Shells

Sugarcane Bagasse Pellet Making

Straw for Pellets Fuel Production

Rice Husk Pellet Processing Technology and Equipment

![How to Assemble Pellet Machine / Pellet Machine Installation - Detailed Guide [2022]](/static/images/placeholder/220x125.png)

How to Assemble Pellet Machine / Pellet Machine Installation - Detailed Guide [2022]

![How to Assemble Pellet Machine / Pellet Machine Installation - Detailed Guide [2022]](/static/images/placeholder/220x125.png)

How to Assemble Pellet Machine / Pellet Machine Installation - Detailed Guide [2022]

Making Fuel Pellets From Peanut Shells

YULONG 8th Generation Centrifugal High Efficient Pellet Machine

Activated Carbon Granulation

![How to Assemble Pellet Machine / Pellet Machine Installation - Detailed Guide [2022]](https://img001.video2b.com/995/file_01650013905751.jpg?x-oss-process=image/resize,m_lfit,w_220)