Injection Molding Manufacturing Services

3D SHAPING has many large and small injection molding machines, which can meet customers' needs for mass processing of plastic products. Injection molding products have the characteristics of optional materials, customizable colors, high precision and low price. It is the most mainstream processing method of plastic products in modern industrial production.

In 3D SHAPING, when you complete the product design and confirm the rapid prototyping, we can make molds for mass production.

Audited supplier

Audited supplier3D SHAPING has a professional technical team and a variety of 3D printing equipment, which can meet different production needs of customers. And can provide customers with a complete set of production solutions, from design to final product production.

Professional

Fast Production

Many Equipment

Rich Materials

One-stop Services

1. Automatic production, short molding processing cycle and high production efficiency

2. Plastic parts with metal or non-metal inserts with diversified shapes and accurate dimensions

3. The quality of injection molded products is stable

4. The process has a wide range of application

Disadvantages:

1. The price of injection molding equipment is high

2. The structure of injection mold is complex

3. The production cost is high and is not suitable for the production of single piece and small batch plastic parts

4. In the early stage, we need to make molds, which requires capital and time investment

- Q. How long does it take for injection molding production of my products?A. The production time of mold is 30-45 days, and the production speed is 3000 pieces / day. In addition, the time of transportation and modification of 3D drawings shall be considered.

- Q. What is a one-stop service?A. One stop service means that you can complete product design, prototype verification and mass production in 3D SHAPING.

1. ABS

①Typical application range:

Automobiles (dashboards, tool hatches, wheel covers, mirror boxes, etc.), refrigerators, high-strength tools (hair dryers, blenders, food processors, lawn mowers, etc.), telephone housings, typewriter keyboards , Recreational vehicles such as golf carts and jet skis.

2. PA6

①Typical application range:

Because of its good mechanical strength and rigidity, it is widely used in structural parts. Because of its good wear resistance, it is also used in the manufacture of bearings.

3. PA12

①Typical application range:

Water meters and other commercial equipment, cable sets, mechanical cams, sliding mechanisms and bearings, etc.

4. PA66

①Typical application range:

Compared with PA6, PA66 is more widely used in the automotive industry, instrument housings and other products that require impact resistance and high strength requirements.

5. PBT

①Typical application range:

Household appliances (food processing blades, vacuum cleaner components, electric fans, hair dryer housings, coffee utensils, etc.), electrical components (switches, motor housings, fuse boxes, computer keyboard keys, etc.), automotive industry (radiator grilles) , Body panels, wheel covers, door and window parts, etc.).

6. PC

①Typical application range:

Electrical and commercial equipment (computer components, connectors, etc.), appliances (food processors, refrigerator drawers, etc.), transportation industry

(The front and rear lights, dashboard, etc. of the vehicle).

7. PC+ABS

①Typical application range:

Computer and business machine housings, electrical equipment, lawn and gardening machines, car parts (instrument panels, interior decoration, and wheel covers).

8. PC+PBT

①Typical application range:

Gearboxes, automobile bumpers, and products that require chemical resistance, corrosion resistance, thermal stability, impact resistance, and geometric stability.

9. PE-HD

①Typical application range:

Refrigerator containers, storage containers, household kitchen utensils, sealed lids, etc.

10. PE-LD

①Typical application range:

Bowls, cabinets, pipe connectors

11. PEI

①Typical application range:

Automotive industry (engine parts such as temperature sensors, fuel and air processors, etc.), electrical and electronic equipment (electrical couplings, printed circuit boards, chip housings, explosion-proof boxes, etc.), product packaging, aircraft interior equipment, and medical industry (surgical equipment) , Tool housings, non-implanted devices).

12. PET

①Typical application range:

Automotive industry (structural components such as mirror boxes, electrical components such as headlight mirrors, etc.), electrical components (motor housings, electrical connectors, relays, switches, internal components of microwave ovens, etc.). Industrial applications (pump housings, manual instruments, etc.).

13. PETG

①Typical application range:

Medical equipment (test tubes, reagent bottles, etc.), toys, monitors, light source covers, protective masks, refrigerator fresh-keeping trays, etc.

14. PMMA

①Typical application range:

Automobile industry (signal lamp equipment, instrument panel, etc.), pharmaceutical industry (blood storage container, etc.), industrial applications (video discs, light diffusers), daily consumer goods (beverage cups, stationery, etc.).

15. POM

①Typical application range:

POM has a very low coefficient of friction and good geometric stability, and is especially suitable for making gears and bearings. Because it also has high temperature resistance characteristics, it is also used in pipeline devices (pipe valves, pump housings), lawn equipment, etc.

16. PP

①Typical application range:

Automotive industry (mainly using PP containing metal additives: mudguards, ventilation ducts, fans, etc.), appliances (dishwasher door liners, dryer ventilation ducts, washing machine frames and covers, refrigerator door liners, etc.), Japan Use consumer goods (lawn and garden equipment such as lawnmowers and sprinklers, etc.).

17. PPE

①Typical application range:

Household products (dishwashers, washing machines, etc.), electrical equipment such as controller housings, optical fiber connectors, etc.

18. PS

①Typical application range:

Product packaging, household goods (tableware, trays, etc.), electrical (transparent containers, light source diffusers, insulating films, etc.).

19. PVC

①Typical application range:

Water supply pipes, household pipes, house wall panels, commercial machine housings, electronic product packaging, medical equipment, food packaging, etc.

20. SA

①Typical application range:

Electrics (sockets, housings, etc.), daily commodities (kitchen appliances, refrigerator devices, TV bases, cassette boxes, etc.), automotive industry (headlight boxes, reflectors, dashboards, etc.), household goods (tableware, food knives, etc.) Etc.), cosmetics packaging, etc.

Audited supplier

Audited supplier

Wholesale Application of 3D Printing in Medical Treatment -- Surgical Learning Tool - 3D SHAPING

Best Quality Best 3D Printing of Architectural model - 3D SHAPING Factory

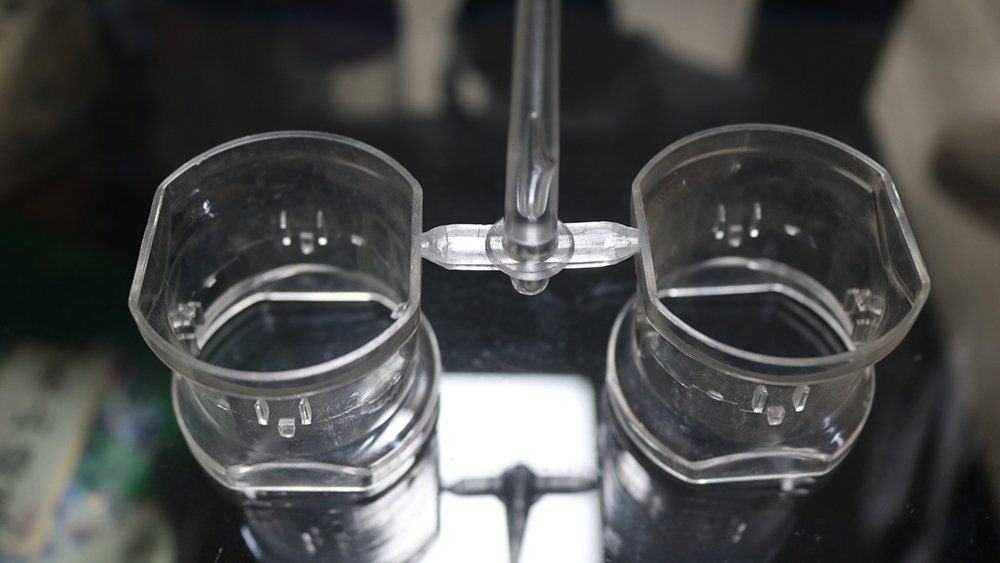

Wholesale Transparent Bone From Silicone Rubber Mold Casting with good price - 3D SHAPING

3D Printing Rockery Model Supplier & manufacturers | 3D SHAPING

3D Printing Rockery Model Supplier & manufacturers | 3D SHAPING

Rapid Prototyping PMMA Transparent Window Supplier & manufacturers | 3D SHAPING

3D Printing Crossbones Supplier & Manufacturers | 3D SHAPING

Application of 3D printing in preoperative medical planning

Application of 3D printing in preoperative medical planning