FDM & Full Color 3D Printing Services

2 years ago

130

Share

In addition to providing a variety of industrial grade 3D printing services, 3D SAHPING also provides other 3D printing services, such as FDM 3D printing and full-color 3D printing.

Comments

No comments received

Suppliers

Hangzhou 3D SHAPING Technology Co., Ltd.

Audited supplier

Audited supplierChina3YRS

58 Xiangshan Road, Wenyan street, Xiaoshan District, Hangzhou, Zhejiang, China

Product details

Comments

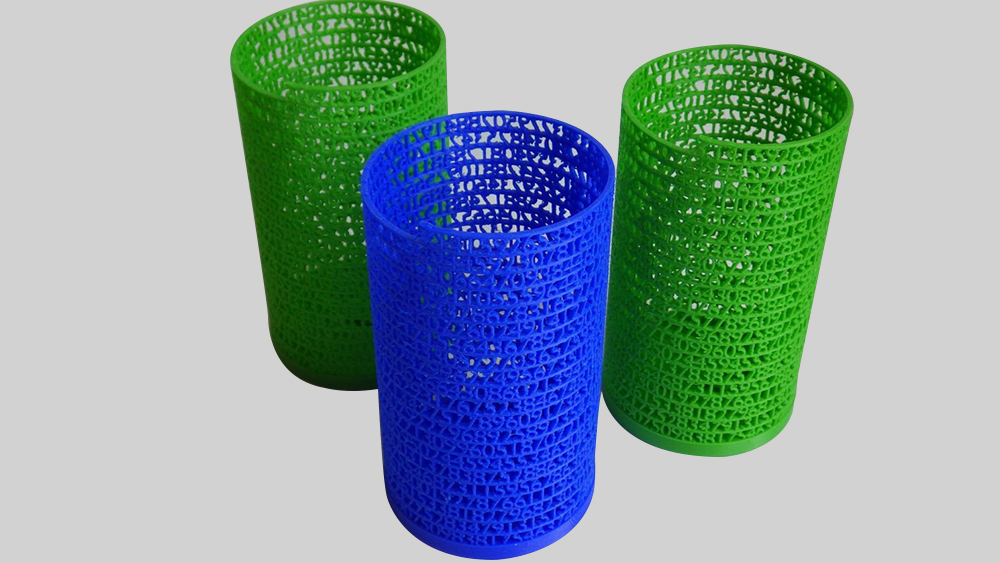

PRODUCT DISPLAY

PRODUCT ADVANTAGES

3D SHAPING has a professional technical team and a variety of 3D printing equipment, which can meet different production needs of customers. And can provide customers with a complete set of production solutions, from design to final product production.

Professional

Fast Production

Many Equipment

Rich Materials

One-stop Services

PRODUCT FEATURES

FDM printing has become very popular all over the world because the machine using this technology is simple and cheap. It usually costs only a few hundred dollars and is the first choice for many DIY lovers. However, individuals will not buy too many FDM machines, and they will be unable to cope with mass production.

In the past, the material used for FDM printer was mainly PLA, which is a degradable environmental protection material. Now FDM can print many composites. If you have printing requirements for different materials, you can contact us.

Full-color 3D printers are even more impressive. 3D SHAPING uses Stratasys equipment, from simulating wood textures to transparent parts. The printable colors have been certified by Pantone, and the original design is 100% restored. Support OBJ/3MF documents. The parts produced by full-color 3D printing do not need to be colored by hand, are not afraid of complicated textures, and do not need to be made separately by internal disassembly.

Disadvantages of full color printing (using polyjet Technology):

1. Support structure is required.

2. The cost of consumables is relatively high. Although photosensitive resin is used as consumables like SLA, the price is higher than SLA.

3. The strength of formed parts is low. Polyjet needs specially developed photosensitive resin. The strength and durability of the formed workpiece are not too high, so it is more suitable for customers who inspect the product design appearance and structure.

2. The cost of consumables is relatively high. Although photosensitive resin is used as consumables like SLA, the price is higher than SLA.

3. The strength of formed parts is low. Polyjet needs specially developed photosensitive resin. The strength and durability of the formed workpiece are not too high, so it is more suitable for customers who inspect the product design appearance and structure.

PRODUCT SPECIFICATION

- Q. Can you make my product?A. You can prepare your ideas and requirements, and then contact us.

- Q. How is 3D printing charged?A. It is generally charged according to the weight of the model.

Suppliers

Hangzhou 3D SHAPING Technology Co., Ltd.

Audited supplier

Audited supplierChina3YRS

58 Xiangshan Road, Wenyan street, Xiaoshan District, Hangzhou, Zhejiang, China

You may also like

Wholesale Application of 3D Printing in Medical Treatment -- Surgical Learning Tool - 3D SHAPING

Best Quality Best 3D Printing of Architectural model - 3D SHAPING Factory

Wholesale Transparent Bone From Silicone Rubber Mold Casting with good price - 3D SHAPING

3D Printing Rockery Model Supplier & manufacturers | 3D SHAPING

3D Printing Rockery Model Supplier & manufacturers | 3D SHAPING

Rapid Prototyping PMMA Transparent Window Supplier & manufacturers | 3D SHAPING

3D Printing Crossbones Supplier & Manufacturers | 3D SHAPING

Application of 3D printing in preoperative medical planning

Application of 3D printing in preoperative medical planning