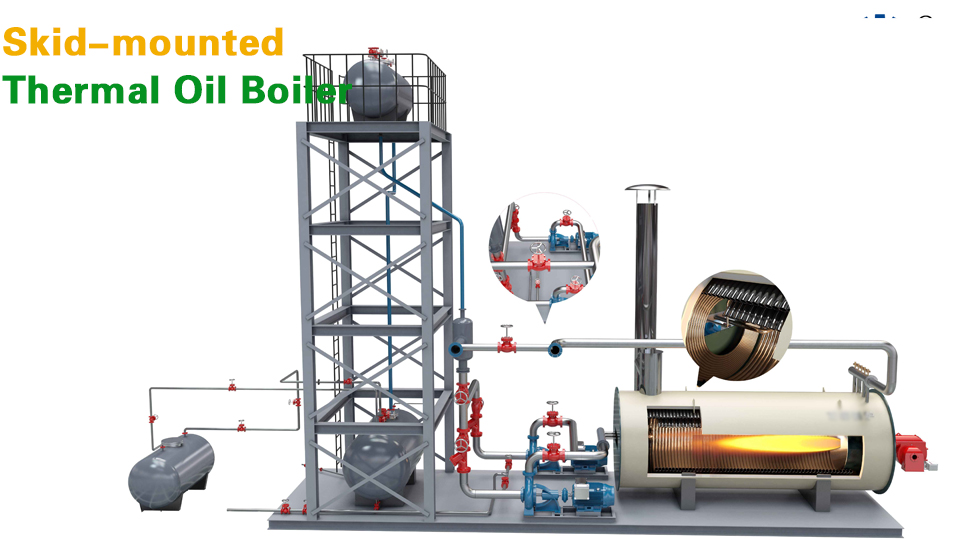

Skid-mounted Thermal Oil Boiler

Skid mounted thermal oil boilers are special designed for customer who do not want to install in their local or want to remove this thermal oil boiler from place to place. Thermal oil heater use diesel or gas or coal as fuel, the thermal oil is heated in the tube. Using the circulating pump to force the liquid thermal oil circulation,and then transporting the heat to the thermal equipment. At last, the oil return back the thermal oil heater.

Audited supplier

Audited supplierSkid mounted thermal oil boilers are special designed for customer who do not want to install in their local or want to remove this thermal oil boiler from place to place. Thermal oil heater use diesel or gas or coal as fuel, the thermal oil is heated in the tube. Using the circulating pump to force the liquid thermal oil circulation,and then transporting the heat to the thermal equipment. At last, the oil return back the thermal oil heater.

Thermal oil heater use diesel or gas or coal as fuel, the thermal oil is heated in the tube. Using the circulating pump to force the liquid thermal oil circulation,and then transporting the heat to the thermal equipment. At last, the oil return back the thermal oil heater. Two return structure enhance the thermal efficiency and lower flue gas temperature. Thicker insulated material layer makes radiating at minimum limit. All heaters are assembly structure which is easy for installation by just connecting system device by pipes. Intelligent system control makes coal fired thermal oil boiler operation easier and more simple. Controller with imitation screen display has auto igniting, burning, circulation pumps control, alarm functions.

Main featurers of Skid-mounted Thermal Oil Boilers:

1.High heat efficiency ,special structure ,could keep total heat efficiency up to 100%.

2.The control of the oil temperature will be concise within the range from -1°C to +1°C.Under low working pressure of 0.8Mpa ,boiler could achieve working temperature of 320°C.

3.There's a connection for the inert gas on the front shroud and it could fill 3 times of the capacity of the furnace with inert gas within 15 minutes in case of emergency to protect it and thus extend the life span.

4.Fully shop-assembled ,save transportation cost and installation fees.

5.The boiler operates automatically and will get rid of misconduct .With a nuclear PLC ,the percentage will be adjusted automatically and the monitor will be ral time ,together with the chainining protection.

Audited supplier

Audited supplier

Solid Fuel Boiler

Bidragon Boiler

Thermal Fluid Heater Advantages

500kw Thermal Oil Boiler Delivery To Russia

High Quality DZH Series Activity Grate Coal Biomass Fired Steam Boiler Wholesale - Bidragon Machinery Co., Ltd.

Skid-mounted Thermal Oil Boiler

Industrial Biomass Wood Chips Coal Solid Fired Boiler

SZL Series Biomass Fired Steam Boiler

Bidragon Gas Fired Thermal Oil Boiler Heater for The Production of Plywood